Method and structure used for board thermal insulation system falling, cracking and seepage repair reinforcing

A thermal insulation system and plate technology, applied in building maintenance, building construction, construction, etc., can solve problems such as poor reinforcement effect, easy deformation, unstable anchoring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

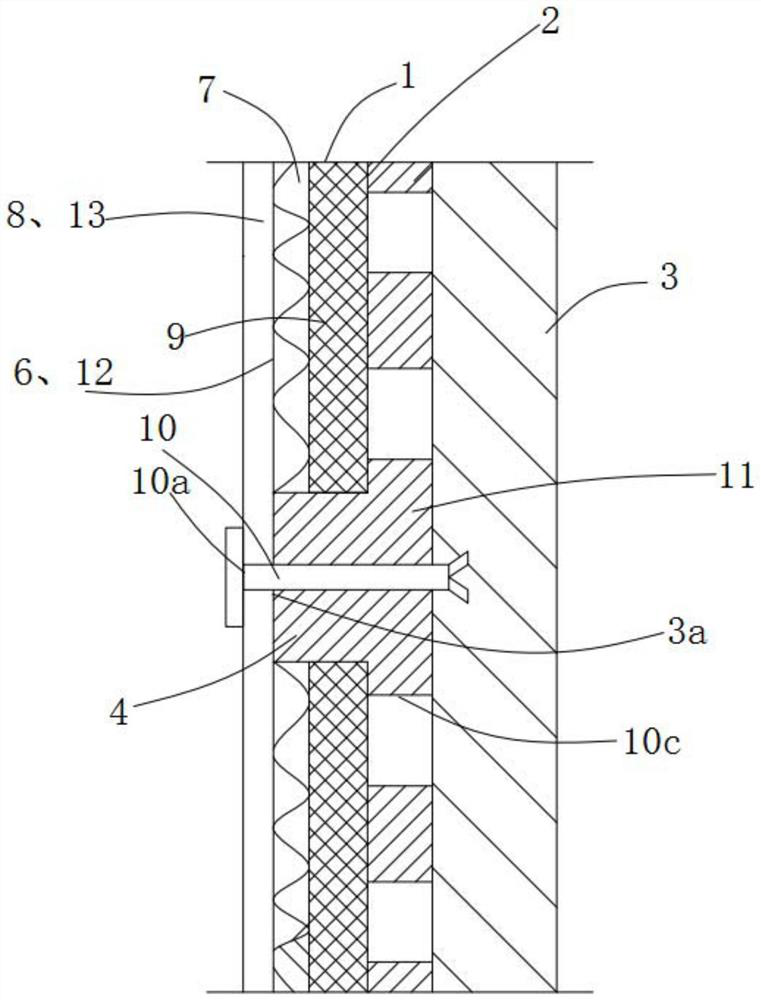

[0072] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0073] see figure 1 , a method for repairing and strengthening board insulation system for shedding, cracking and leakage of the present invention comprises the following steps:

[0074] Step 1: Determine the identification range of the reinforcement area and form a diagnostic report according to the identification range of the reinforcement area, and clean the protective layer on the insulation board 1 within the identification range of the reinforcement area;

[0075] Step 2: Carry out safety calculation and review based on the results provided by the diagnostic report of Step 1;

[0076] Step 3: Identify the reinforcement points within the scope of the reinforcement area identification, and determine the opening depth of each reinforcement point;

[0077] Step 4: Open the glue injection hole 2 on the insulation board 1 of each reinforcemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com