Circular screen printer device with antiskid roller

A rotary screen printing and roller technology, applied in screen printing presses, printing presses, rotary printing presses, etc., can solve the problems of lifting the edges of both sides of the guide belt, slipping between the guide belt and the roller, affecting the appearance, etc. Solve the effect of easy to produce edge warping, smooth running of the guide belt, and ingenious design concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

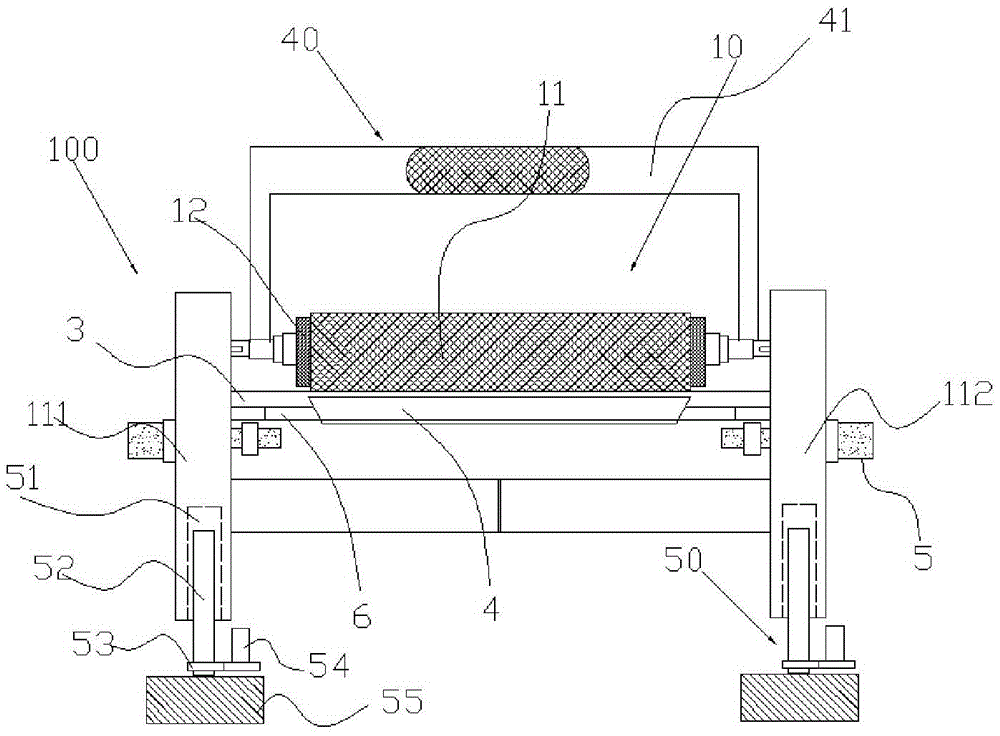

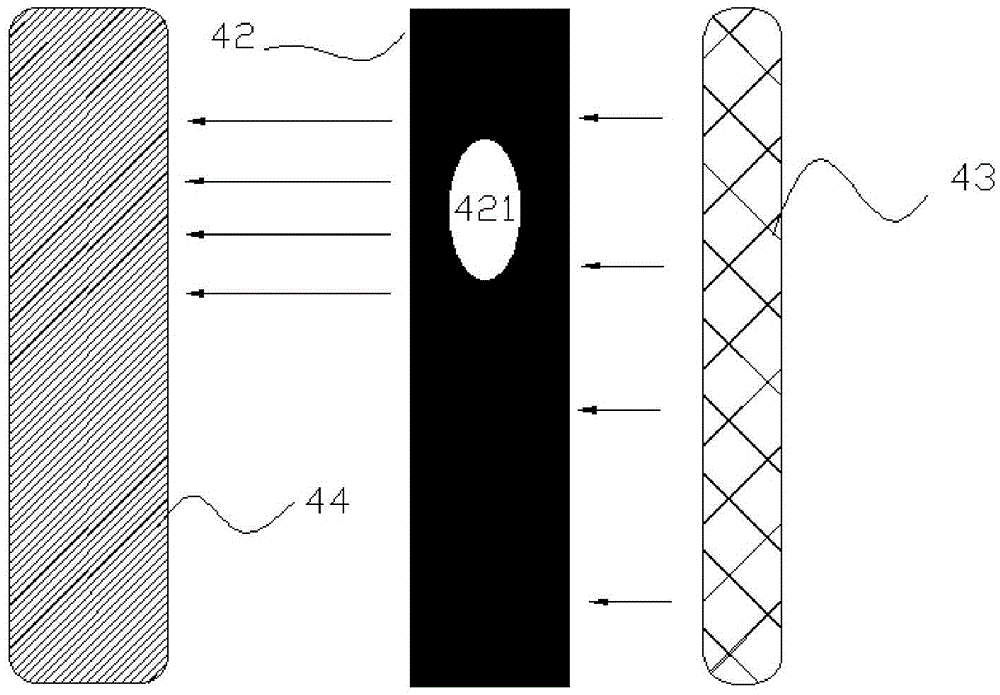

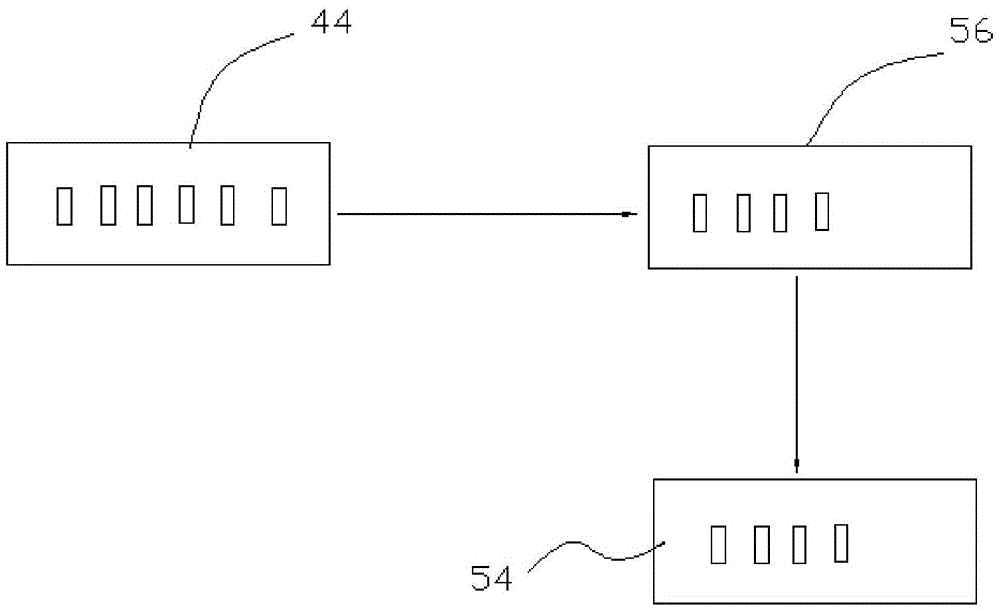

[0021] Such as Figure 1 to Figure 5 A rotary screen printing machine device with non-slip rollers is shown, including a rotary screen, a printing guide belt 3, etc., and is characterized in that it also includes a strip-shaped groove 4 arranged below the rotary screen and the printing guide belt, The outer sides of the two ends of the elongated groove 4 along the lengthwise direction are fixedly connected with a fixing frame 6, and the fixing frame 6 is fixed on the first column 111 and the second column 112 arranged vertically, and the first column 111 The roller printing device 10 is fixed on the second column 112, and the two ends of the roller printing device 10 are connected to the first column 111 and the second column 112 in a rotatable manner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com