Multifunctional protective material with high-pressure water-jet-cutting resistance and preparation method thereof

A protective material, water jet technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of low production efficiency and yield, achieve high degree of automation, easy filtration and separation, and process automation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 100 grams of novolac epoxy resin (NPPN-638S), 0.2 grams of triphenylphosphine, and 0.1 grams of hydroquinone into the reactor, raise the temperature to 105°C, add 45 grams of acrylic acid and 90 grams of 3,7-dimethyl - The mixed solution of 6-octenoic acid was slowly and continuously added dropwise for 50 minutes with a constant pressure funnel, and after the dropwise addition was completed, it was kept at 105° C. for 2 hours to obtain a novolak epoxy acrylic resin.

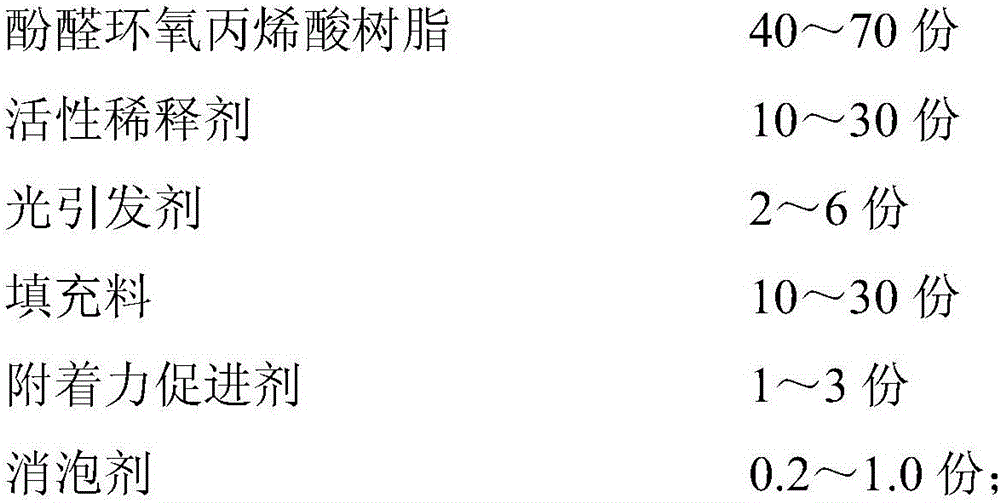

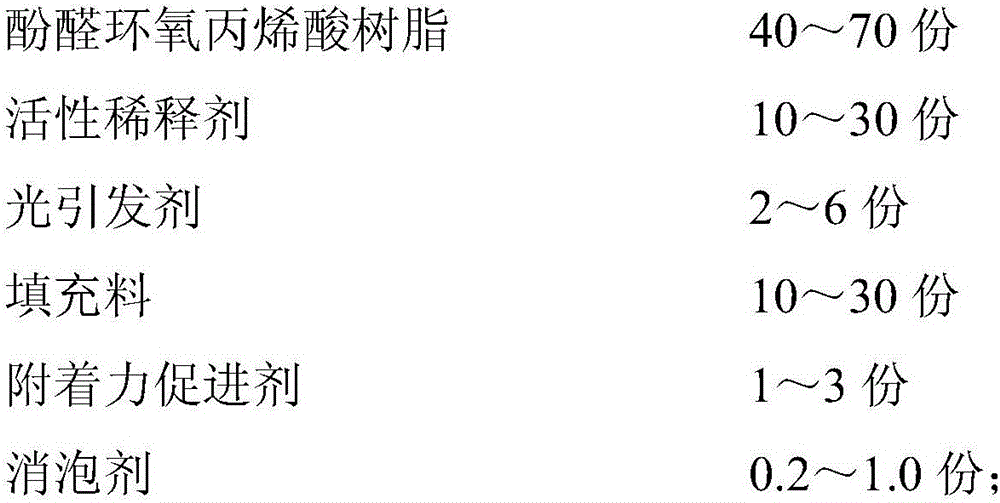

[0036] Weigh the following raw materials in parts by weight: 40 parts of novolac epoxy acrylic resin, 20 parts of alkoxylated nonylphenol acrylate, 2 parts of 1-hydroxycyclohexyl phenyl ketone, 15 parts of talcum powder, 15 parts of barium sulfate, acryloyl trimethyl 1 part of oxysilane, 0.2 part of defoamer. Mix novolac epoxy acrylic resin with active diluent, add photoinitiator, filler, defoamer, form a uniform viscous liquid after high-speed stirring, put the viscous liquid into a grinder and grind ...

Embodiment 2

[0038] Add 100 grams of novolac epoxy resin (NPPN-638S), 0.4 grams of triphenylphosphine, and 0.2 grams of hydroquinone into the reactor, raise the temperature to 95°C, add 30 grams of acrylic acid and 130 grams of 3,7-dimethyl - The mixed solution of 6-octenoic acid was slowly and continuously added dropwise for 90 minutes with a constant pressure funnel, and after the dropwise addition was completed, it was kept at 130° C. for 4 hours to obtain a novolac epoxy acrylic resin.

[0039] Weigh the following raw materials in parts by weight: 70 parts of phenolic epoxy acrylic resin, 10 parts of lauryl acrylate, 6 parts of 2-isopropylthioxanthone, 10 parts of talcum powder, 3 parts of hydroxyethyl acryloyl phosphate, disinfectant 1.0 parts of foaming agent. Mix novolac epoxy acrylic resin with active diluent, add photoinitiator, filler, defoamer, form a uniform viscous liquid after high-speed stirring, put the viscous liquid into a grinder and grind to obtain the protective materi...

Embodiment 3

[0041] Add 100 grams of novolac epoxy resin (NPPN-638S), 0.3 grams of triphenylphosphine, and 0.1 grams of hydroquinone into the reactor, raise the temperature to 101°C, add 35 grams of acrylic acid and 110 grams of 3,7-dimethyl - The mixed solution of 6-octenoic acid was slowly and continuously added dropwise for 70 minutes with a constant pressure funnel, and after the dropwise addition was completed, it was kept at 105° C. for 3 hours to obtain a novolac epoxy acrylic resin.

[0042]Weigh the following raw materials in parts by weight: 50 parts of novolak epoxy acrylic resin, 30 parts of pentaerythritol tetraacrylate, 2-methyl-2-(4-morpholinyl)-1-[4-(methylthio)phenyl] - 4 parts of 1-acetone, 12 parts of zinc stearate, 2 parts of methacryl trippropoxysilane, 0.5 part of defoamer. Mix novolac epoxy acrylic resin with active diluent, add photoinitiator, filler, defoamer, form a uniform viscous liquid after high-speed stirring, put the viscous liquid into a grinder and grind t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com