Braided fabric binding presser foot for sewing machine

A technology for knitting fabrics and sewing machines, applied to sewing machine components, sewing equipment, cloth pressing mechanisms, etc., can solve the problems of difficulty in sewing, skewed sewing of knitted fabrics, etc., and achieve the effect of no warping and missing edges and neat sewing lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with drawings and embodiments.

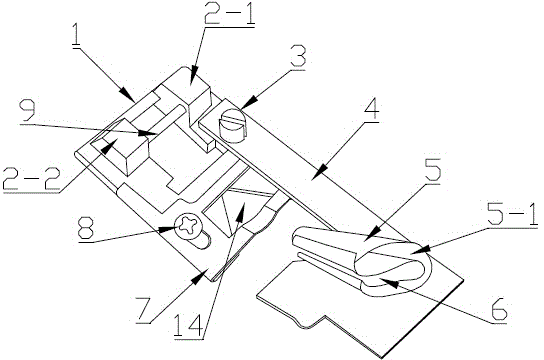

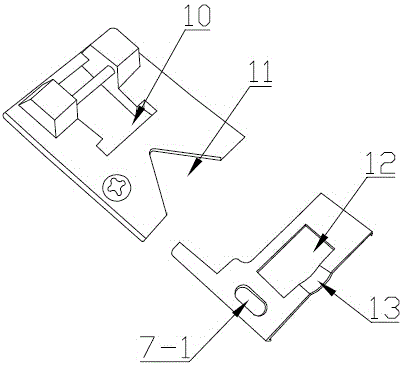

[0010] Such as figure 1 and figure 2 As shown, the present invention includes a presser foot bottom plate 1 and an edge-wrapping connecting plate 4 . The front end of the presser foot base plate 1 is provided with a triangular fork 11, and the fork 11 is covered with a sliding piece 7. The sliding sheet 7 is provided with a through hole 12 , and the through hole 12 and the fork 11 form a braided perforation 14 . The front end of the through hole 12 is provided with a guiding groove 13, which is used for receiving the braided fabric. A first bump 2 - 1 and a second bump 2 - 2 are welded on the bottom plate 1 of the presser foot, and the first bump 2 - 1 and the second bump 2 - 2 are connected by pins 9 . The front ends of the first protruding block 2-1 and the second protruding block 2-2 are provided with movable stitch grooves 10 . Pin is the important part that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com