Preparation method of polyimide film

A technology of polyimide film and polyamic acid glue, which is applied in the field of preparation of polyimide film, can solve the problems of unfavorable size stability, etc., and achieve the effects of reducing thermal expansion coefficient, high electrical strength, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

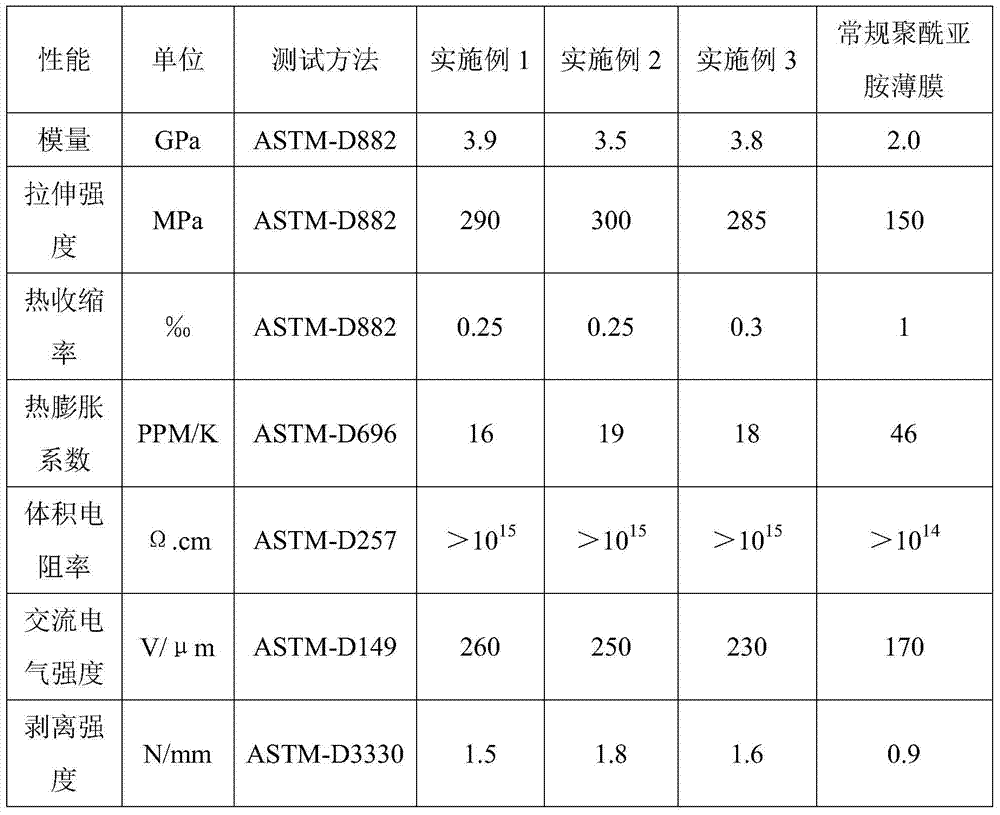

Examples

Embodiment 1

[0021] The preparation method of polyimide film, comprises the following steps:

[0022] (1) Under the condition of normal pressure filled with nitrogen in the kettle body at 45°C, first dissolve 4,4'-diaminodiphenyl ether in dimethylacetamide solvent, and then add pyromellitic dianhydride to carry out polymerization reaction , the reaction time was 4 hours, the mol ratio of pyromellitic dianhydride and 4,4'-diaminodiphenyl ether was 1:1.01, and the polyamic acid glue A with a solid content of 20wt% was obtained (stirring speed in the whole reaction process 90r / min);

[0023] (2) Under the condition of normal pressure filled with nitrogen in the kettle body at 45°C, first dissolve p-phenylenediamine in dimethylacetamide solvent, and then add 3,3',4,4'-benzophenone tetra Formic dianhydride is polymerized, the reaction time is 4.5 hours, the molar ratio of 3,3',4,4'-benzophenone tetracarboxylic dianhydride and p-phenylenediamine is 1:1.004, and the solid content is 20wt%. Poly...

Embodiment 2

[0029] The preparation method of polyimide film, comprises the following steps:

[0030] (1) Under the condition of normal pressure filled with nitrogen in the kettle body at 35°C, first dissolve 4,4'-diaminodiphenyl ether in dimethylacetamide solvent, and then add pyromellitic dianhydride to carry out polymerization reaction , the reaction time was 4 hours, the mol ratio of pyromellitic dianhydride and 4,4'-diaminodiphenyl ether was 1:1.007, and the polyamic acid glue A with a solid content of 17% was obtained (stirring speed in the whole reaction process 90r / min);

[0031] (2) Under the condition of normal pressure filled with nitrogen in the kettle body at 55°C, first dissolve p-phenylenediamine in dimethylacetamide solvent, and then add 3,3',4,4'-benzophenone tetra Formic dianhydride is polymerized, the reaction time is 4.5 hours, the molar ratio of 3,3',4,4'-benzophenone tetracarboxylic dianhydride to p-phenylenediamine is 1.007, and a polyamide with a solid content of 2...

Embodiment 3

[0037] The preparation method of polyimide film, comprises the following steps:

[0038](1) Under the condition of normal pressure filled with nitrogen in the kettle body at 55°C, first dissolve 4,4'-diaminodiphenyl ether in dimethylacetamide solvent, and then add pyromellitic dianhydride to carry out polymerization reaction , the reaction time was 4 hours, the mol ratio of pyromellitic dianhydride and 4,4'-diaminodiphenyl ether was 1.013, and the polyamic acid glue A with a solid content of 23wt% was obtained (the stirring speed of the whole reaction process was 90r / min);

[0039] (2) Under the condition of normal pressure filled with nitrogen in the kettle body at 35°C, first dissolve p-phenylenediamine in dimethylacetamide solvent, and then add 3,3',4,4'-benzophenone tetra Formic dianhydride is polymerized, the reaction time is 4.5 hours, the molar ratio of 3,3',4,4'-benzophenone tetracarboxylic dianhydride and p-phenylenediamine is 1:1.001, and the solid content is 17wt%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com