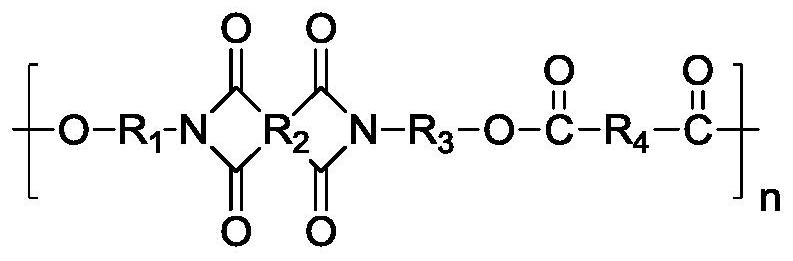

A kind of polyimide film with low thermal expansion coefficient and preparation method thereof

A polyimide film, low thermal expansion coefficient technology, applied in the field of optical materials, can solve the problems of reducing the thermal thermal expansion coefficient, damage the mechanical properties of the film, etc., to achieve the effect of reducing the thermal expansion coefficient, good bonding performance, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

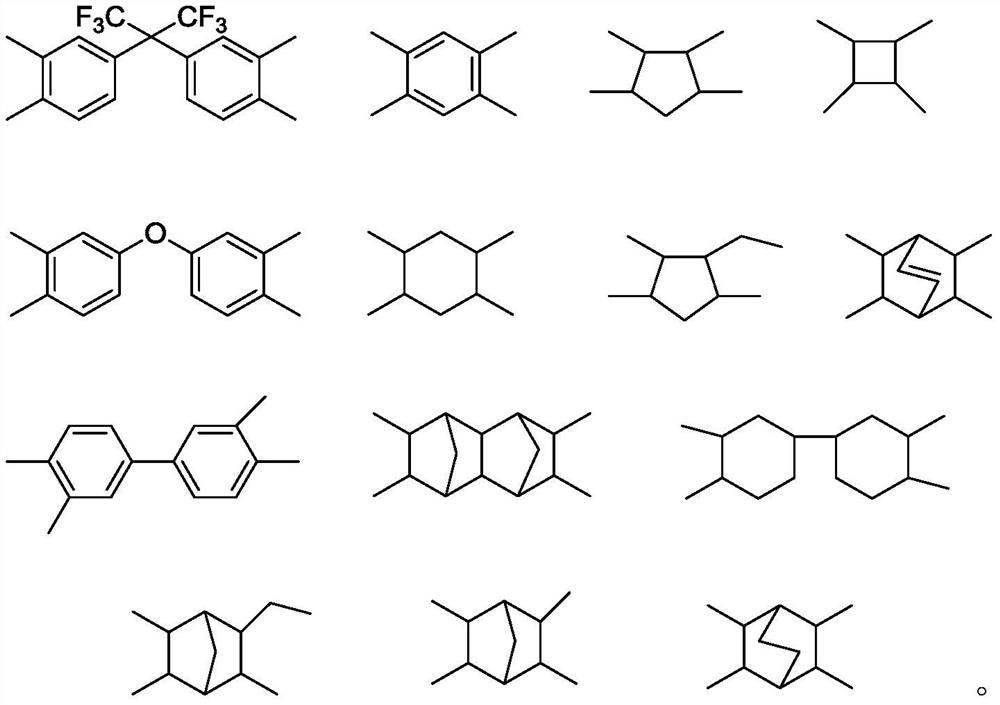

[0033] A kind of polyimide film of low coefficient of thermal expansion, its preparation method comprises:

[0034] Preparation of S1, diphenol monomer:

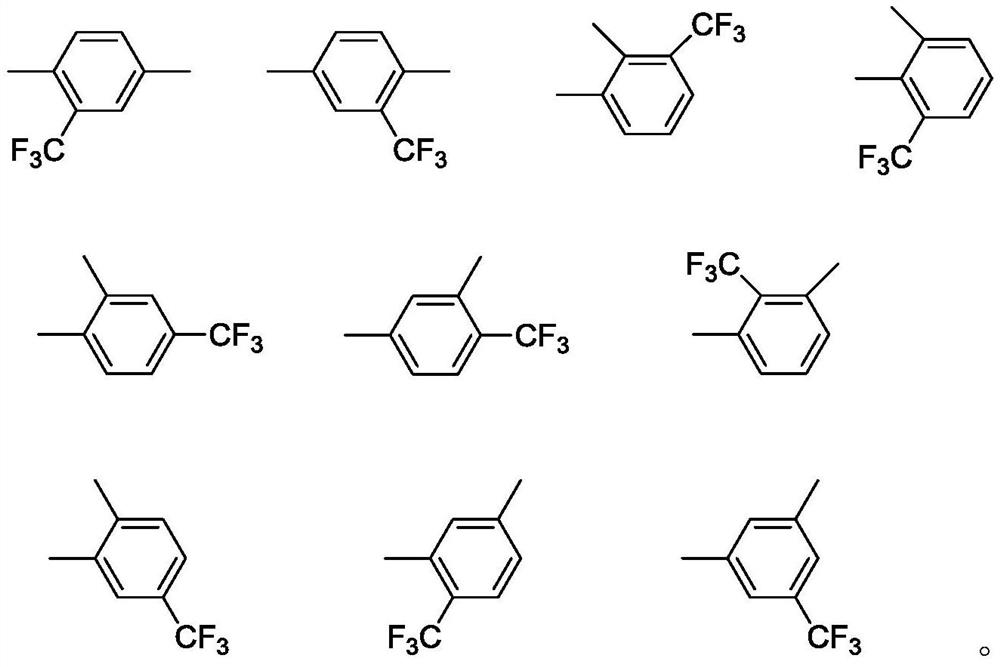

[0035] Under nitrogen protection, 4.4424g (10mmol) 4,4'-(hexafluoroisopropylene) diphthalic anhydride (hereinafter referred to as 6FDA), 3.5426g (20mmol) 4-amino-2-trifluoromethylphenol, Add 32ml of anhydrous N-methylpyrrolidone (hereinafter referred to as NMP) into the reaction flask, stir and react at room temperature for 8 hours, after removing the solvent, the diphenol monomer is prepared, and its structural formula is as follows:

[0036]

[0037] S2, the preparation of polyester amic acid:

[0038] Under nitrogen protection, 7.9848g (10mmol) of the above-mentioned diphenol monomer, 2.0302g (10mmol) of terephthaloyl chloride (hereinafter referred to as CC44), and 38ml of anhydrous N-methylpyrrolidone were added to the reaction flask at room temperature. Stirred and reacted for 8 hours to obtain the polyester amic a...

Embodiment 2

[0043] A kind of polyimide film of low thermal expansion coefficient, the preparation method of this film is identical with embodiment 1, except in the preparation of diphenol monomer, 4.4424g (10mmol) 6FDA, 3.5426g (20mmol) 4-amino- 3-Trifluoromethylphenol and 32ml of anhydrous NMP were added into the reaction flask for reaction, and the relevant performance test results of the polyimide film thus obtained are also shown in Table 1.

Embodiment 3

[0045]A kind of polyimide film of low thermal expansion coefficient, the preparation method of this film is identical with embodiment 1, except in the preparation of diphenol monomer, 4.4424g (10mmol) 6FDA, 3.5426g (20mmol) 2-amino- 4-Trifluoromethylphenol and 32ml of anhydrous NMP were added into the reaction flask for reaction, and the relevant performance test results of the polyimide film thus obtained are also shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com