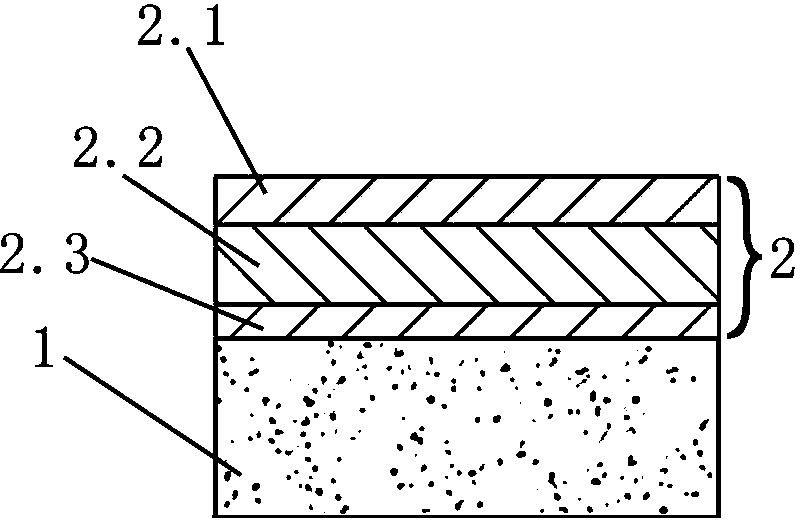

FDM (fused deposition modeling) 3 D (three dimensional) printing cold plate molding resin membrane

A technology of resin film and cold plate, applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of high cost of consumables, low safety, large machine loss, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh 44kg of high-density polyethylene, 5.5kg of linear low-density polyethylene, 2.75kg of color masterbatch (white), calcium carbonate (CaCO 3 ) 2.75kg mixed evenly, sheared by the screw of the co-extrusion blown film machine, melted to the die for extrusion, and then blown, cooled, rotated and drawn, cut and wound to prepare the base layer to obtain the base layer coil; the prepared base The thickness of the layer is 60 μm;

[0023] (2) Put the prepared base layer coil on the glue laying machine, spread ethylene-vinyl acetate copolymer (30kg) on the base layer, cut and roll, prepare the hot melt layer, and obtain the hot melt layer / base layer roll material; the thickness of the prepared hot-melt layer is 60 μm;

[0024] (3) Put the hot melt layer / base layer coil on the glue machine again, spread the oily self-adhesive (15kg) on the other side of the base layer and cut and roll it, and add Separate the release paper to complete the preparation of the FDM 3D...

Embodiment 2

[0026] (1) Weigh 51kg of high-density polyethylene, 3kg of linear low-density polyethylene, calcium carbonate (CaCO 3 ) 6kg mixed evenly, sheared by the screw of the co-extrusion blown film machine, melted to the die for extrusion, and then blown, cooled, rotated and drawn, cut and wound to prepare the base layer to obtain the base layer coil; the prepared base layer The thickness is 109μm;

[0027] (2) Put the prepared base layer coil on the glue laying machine, spread ethylene-vinyl acetate copolymer (25kg) on the base layer, cut and roll, prepare the hot melt layer, and obtain the hot melt layer / base layer roll material; the thickness of the prepared hot-melt layer is 83 μm;

[0028] (3) Put the hot melt layer / base layer coil on the glue machine again, spread the oily self-adhesive (15kg) on the other side of the base layer and cut and roll it, and add Separate the release paper to complete the preparation of the FDM 3D printing cold plate forming resin film; the thic...

Embodiment 3

[0030] (1) Weigh 37.5kg of high-density polyethylene, 7.5kg of linear low-density polyethylene, and 5kg of calcium carbonate (CaCO3) to mix evenly, cut and melt to the die head for extrusion through the screw of a co-extrusion blown film machine, and then blow , cooling, rotating traction, cutting and winding, preparing the base layer, and obtaining the base layer coil; the thickness of the prepared base layer is 45.5 μm;

[0031] (2) Put the prepared base layer coil on the glue laying machine, spread ethylene-vinyl acetate copolymer (30kg) on the base layer, cut and roll, prepare the hot melt layer, and obtain the hot melt layer / base layer roll material; the thickness of the prepared hot-melt layer is 50 μm;

[0032] (3) Put the hot melt layer / base layer coil on the glue machine again, spread the oily self-adhesive (20kg) on the other side of the base layer, cut and roll, and add Separate the release paper to complete the preparation of the FDM 3D printing cold plate for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com