A swing type cutting knife device

A technology of swinging device and slitting knife, which is applied in the directions of transportation and packaging, sending objects, and thin material processing, etc., can solve the problems of deviation, shrinkage thickness of edge layer heat shrinkable film, uneven thickness of heat shrinkable film, etc. The problem of edge warping and the effect of improving the quality of product packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

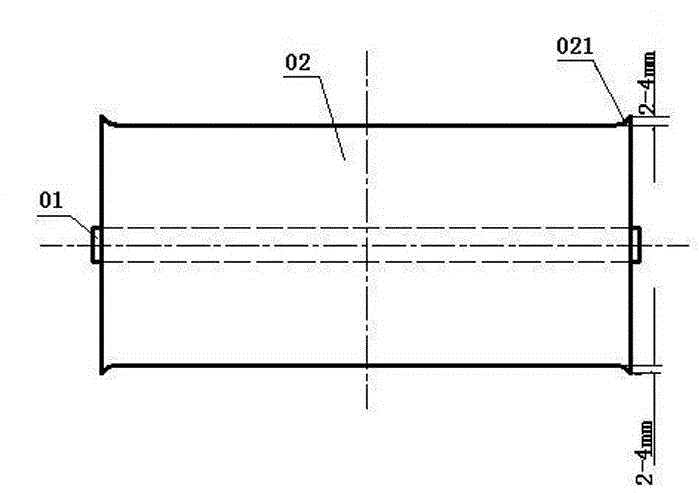

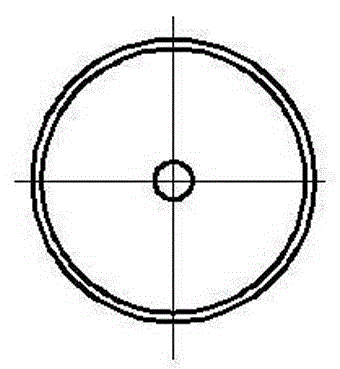

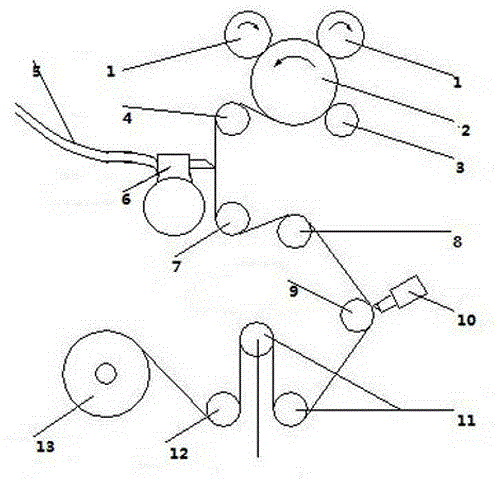

[0022] Such as figure 2 As shown, the present invention provides a swinging slitting knife device, including a winding shaft 1, fixed speed rollers 2, 3, positioning rollers 4, power rollers 8, detection rollers 9, CCD sensors 10, enabling rollers 11, rolling Composed of roller 12, unwinding and deviation correction actuator 13, and swing device. Among them, the winding shaft 1, the fixed speed roller 2, 3, the positioning roller 4, the power roller 8, the detection roller 9, the CCD sensor 10, the energizing roller 11, the flattening roller 12, and the unwinding and deviation correcting actuator 13 are sequentially connected. Swing device is connected with cutter arm fixed track 14, and cutting blade 15 is fixed on the cutter arm, and heat-shrinkable film 18 passes between cutting blade 15 and positioning roller 4,7 and cuts.

[0023] In order to improve the cutting efficiency, the number of cutting knives is 2-20. The preferred number of slitting blades is 6, 8 or 12, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com