A kind of preparation method of plywood for wooden floor

A technology for wood flooring and veneer, which is applied in the field of home decoration, can solve the problems of poor bonding strength and unfavorable long-term use of wood floors, and achieves the effect of strong bonding strength and improving bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

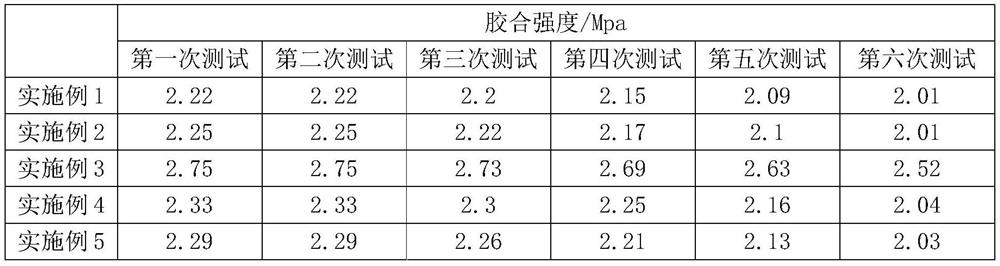

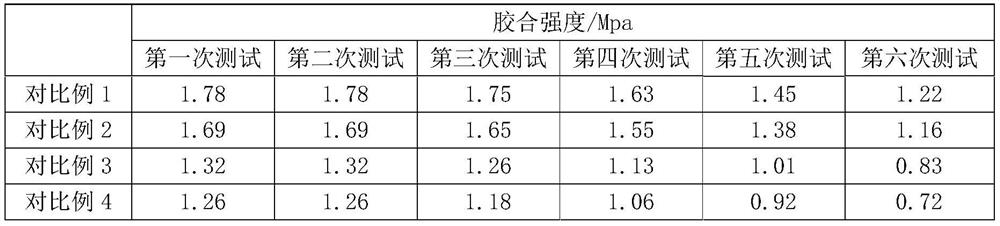

Examples

Embodiment 1

[0032] Method for preparing one kind of wood veneer, comprising the steps of:

[0033] (1) substrate and the faceplate is selected from:

[0034] Select sliced pineapple wood into boards, panels and select from the substrate, wherein the warpage of the substrate is less than 1%, the panel warpage less than 0.8%, the substrate and the panel placed in the baking oven to a moisture content of 6%;

[0035] (2) Configuration Adhesive:

[0036] Adhesive material comprising the following composition by weight:

[0037] Dehydrated urea resin: 90 parts;

[0038] Polyvinyl acetate: 15 parts;

[0039] Titanate coupling agent: 1 part;

[0040] Chlorinated olefin: 0.5 parts;

[0041] Urea: 0.1 parts;

[0042] Chloride: 0.5 parts;

[0043] Flour: 10 parts;

[0044] Wherein the dehydration of urea-formaldehyde resin solids content of 50%, a viscosity of Iwata cup viscosity 12S NK-2, each of the above raw materials are mixed and stirred until a viscous pasty liquid glue, acquired;

[0045] (3) ...

Embodiment 2

[0050] Method for preparing one kind of wood veneer, comprising the steps of:

[0051] (1) substrate and the faceplate is selected from:

[0052] Select Okan sliced wood into boards, panels and select from the substrate, wherein the warpage of the substrate is less than 1%, the panel warpage less than 0.8%, the substrate and the panel placed in the baking oven to a moisture content of 9% ;

[0053] (2) Configuration Adhesive:

[0054] Adhesive material comprising the following composition by weight:

[0055] Dehydrated urea resin: 95 parts;

[0056] Polyvinyl acetate: 20 parts;

[0057] A titanate coupling agent: 2 parts;

[0058] Chlorinated olefin: 1;

[0059] Urea: 0.5 parts;

[0060] Ammonium sulfate: 1 part;

[0061] Flour: 15 parts;

[0062] Wherein the dehydration urea-formaldehyde resin solids content of 55% and a viscosity Iwata NK-2 viscosity cup 15s, each of the above raw materials are mixed and stirred until a viscous pasty liquid glue, acquired;

[0063] (3) coating...

Embodiment 3

[0068] Method for preparing one kind of wood veneer, comprising the steps of:

[0069] (1) substrate and the faceplate is selected from:

[0070] Select ash sliced into a plate, and panel select from the substrate, wherein the warpage of the substrate is less than 1%, the panel warpage less than 0.8%, the substrate and the panel placed in the baking oven to a moisture content of 7%;

[0071] (2) Configuration Adhesive:

[0072] Adhesive material comprising the following composition by weight:

[0073] Dehydrated urea resin: 93 parts;

[0074] Polyvinyl acetate: 16 parts;

[0075] A titanate coupling agent: 1.5 parts;

[0076] Chlorinated olefin: 1;

[0077] Urea: 0.1 parts;

[0078] Chloride: 0.6 parts;

[0079] Flour: 12 parts;

[0080] Titanium dioxide: 0.5 parts;

[0081]Among them, the solid content of the dehydratordehyde resin is 52%, the viscosity is the viscosity 13S of the NK-2 cup viscosity 13S, and the mixture is mixed to the colloidal viscous liquid, which is set;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| warpage | aaaaa | aaaaa |

| warpage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com