Full screen, terminal equipment and manufacturing method of terminal equipment

A terminal equipment, full-screen technology, applied in branch equipment, TV, color TV, etc., can solve problems such as poor user experience, troublesome operation, uneven dispensing process, etc., to solve the problem of camera being interfered by light, occupation Small space, avoiding the effect of complex dispensing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

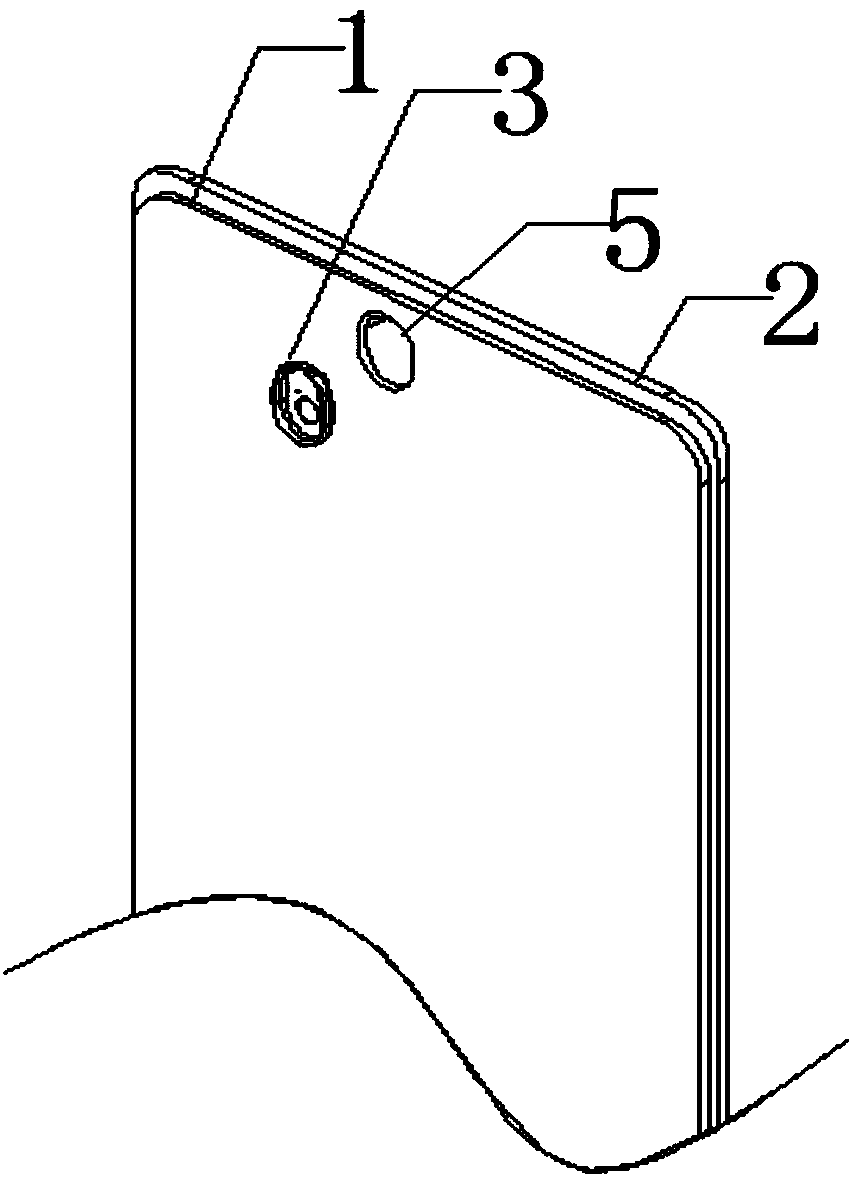

[0066] Such as image 3 As shown, the schematic exploded view of the structure of the first embodiment proposed by the full screen of the present invention, the full screen includes the LCM component 1, the TP cover plate 2 and the light-shielding member 3, the TP cover plate 2 is pasted on the LCM component 1, and the The LCM module 1 is provided with a mounting groove 5 for embedding the camera 4, and a light shielding member 3 covering the lens of the camera 4 is provided in the mounting groove 5, and is used to block the light emitted by the full screen from entering the shooting of the camera 4. area (such as Figure 9 As shown), the position of the shading member 3 corresponding to the lens of the camera 4 is provided with a through hole 6, so that the camera 4 can take pictures through the through hole 6.

[0067] Specifically, in order to better avoid the interference of the light emitted by the full screen and affect the work of the camera 4, the light-shielding memb...

Embodiment 2

[0075] Figure 4 A schematic structural diagram of the second embodiment proposed for the full screen of the present invention; Figure 5 for Figure 4 The Y-Y cross-sectional view; such as Figure 4 and Figure 5 As shown, the present invention proposes a second embodiment of the full screen. The technical solution of the second embodiment is basically similar to that of the first embodiment, the difference is that the installation groove 5 of the second embodiment is U-shaped; and the shading member 3 is an open cylindrical structure, and the through hole 6 is arranged 3 in the middle of the cylinder bottom, the cylinder cross section of the shading member 3 is U-shaped. In this way, the structure of the shading member 3 can be further simplified under the premise of ensuring that the light emitted by the full screen does not interfere with the work of the camera 4 , which not only reduces equipment costs, but also takes up less space.

[0076] The full screen of Embodi...

Embodiment 3

[0085] Figure 6 A schematic structural diagram of the third embodiment provided for the terminal device of the present invention; Figure 7 for Figure 6 The schematic diagram of the structural decomposition, such as Figure 6 and Figure 7 As shown, the present invention also proposes a terminal device, which includes a body, a camera 4 component and a full screen. The body and the camera 4 component are existing technologies in the field, and will not be described in detail in the present invention. The camera 4 components include Figure 6 and Figure 7 The front camera 4 and the rear camera 4 (not shown in the figure).

[0086] Specifically, the terminal device may be other intelligent terminal devices such as a mobile terminal and a palmtop computer, which are not listed here.

[0087] The full screen of the terminal device in the third embodiment includes an LCM component 1, a TP cover 2 and a light-shielding member 3, the TP cover 2 is attached to the LCM compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com