Electromechanical integrated novel omnibearing structure wheel device

An all-in-one, new technology, applied in the directions of wheels, transportation and packaging, vehicle components, etc., can solve problems such as control failure, vibration, torque imbalance, etc., to achieve the effect of improved manufacturing process, simple control algorithm, and avoidance of high peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

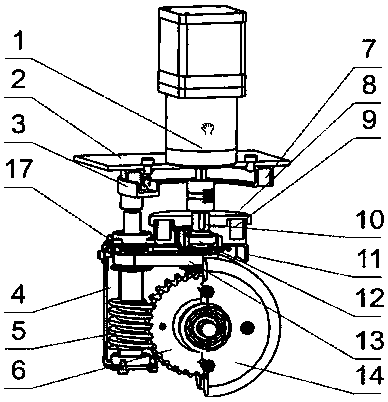

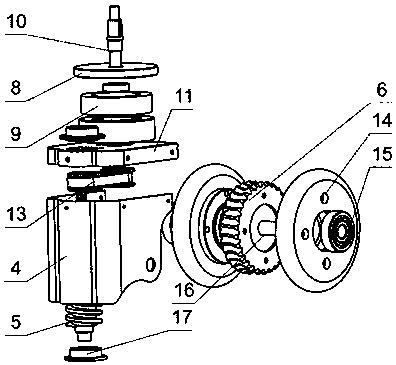

[0015] The present invention will be further described through the following embodiments in conjunction with the accompanying drawings.

[0016] The present invention is realized like this (as figure 1 , 2 shown); the geared motor 1 is installed on the base 2, and the positioning electromagnet 7 and the positioning slip ring 3 are installed on the back of the base 1. The output shaft of the geared motor 1 is directly connected to the upper journal of the transmission shaft 10; The transmission shaft 10 is connected by a key to realize synchronous rotation; the transmission shaft 10 is fixed on the rolling bearing A12 provided in the reversing electromagnet 9 and is concentric with the position of the reversing electromagnet 9, and the lower end journal of the transmission shaft 10 is connected with the transmission pair 13 to the worm 5 transfer torque; the reversing electromagnet 9 is fixed on the wheel frame end cover 11, and the wheel frame end cover 11 is fixed on the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com