Hydraulic jacking device capable of moving front and back

A technology of jacking device and forward and backward movement, applied in the direction of lifting device, lifting frame, etc., can solve the problems of inconvenient use, achieve the effect of easy to use, convenient to use and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

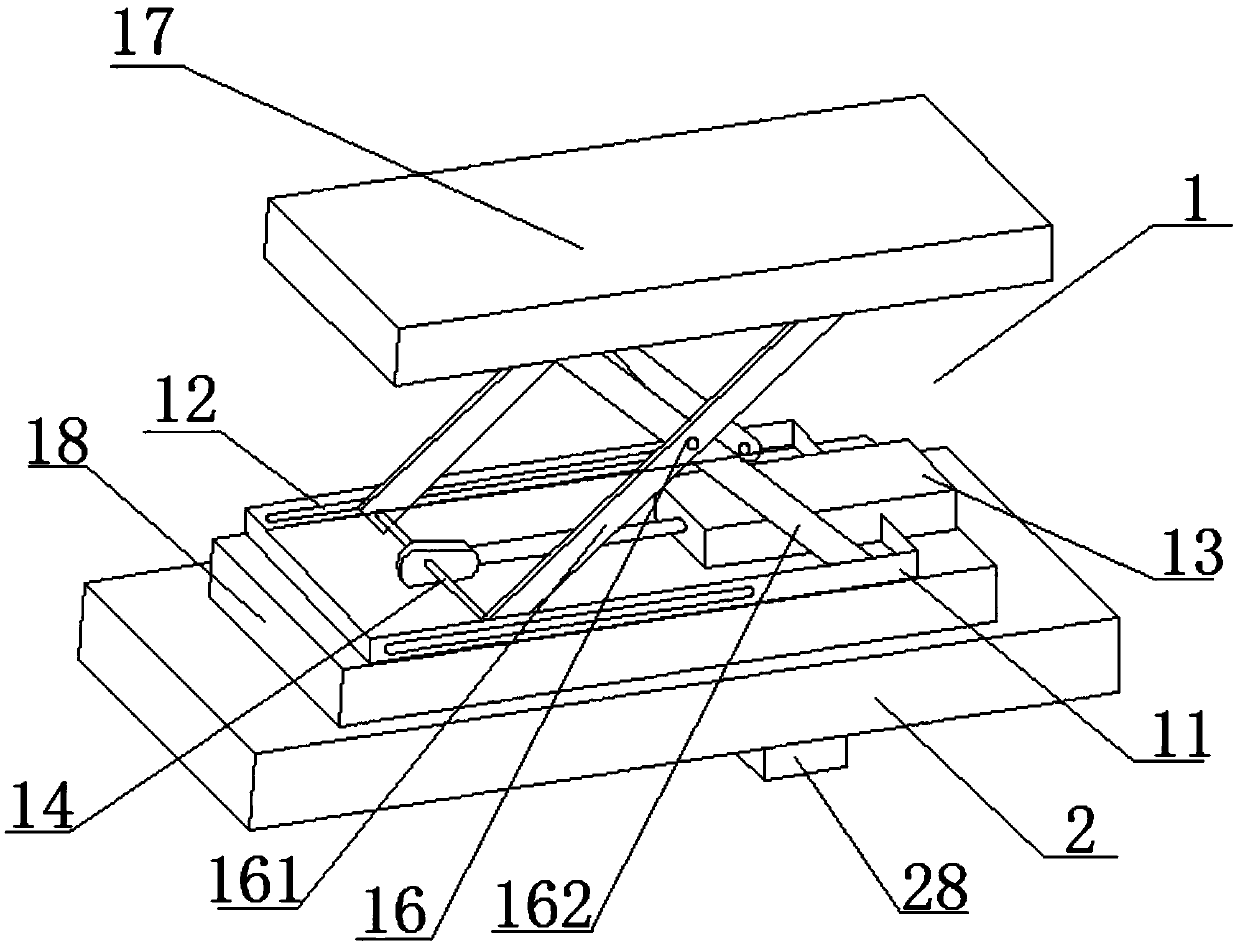

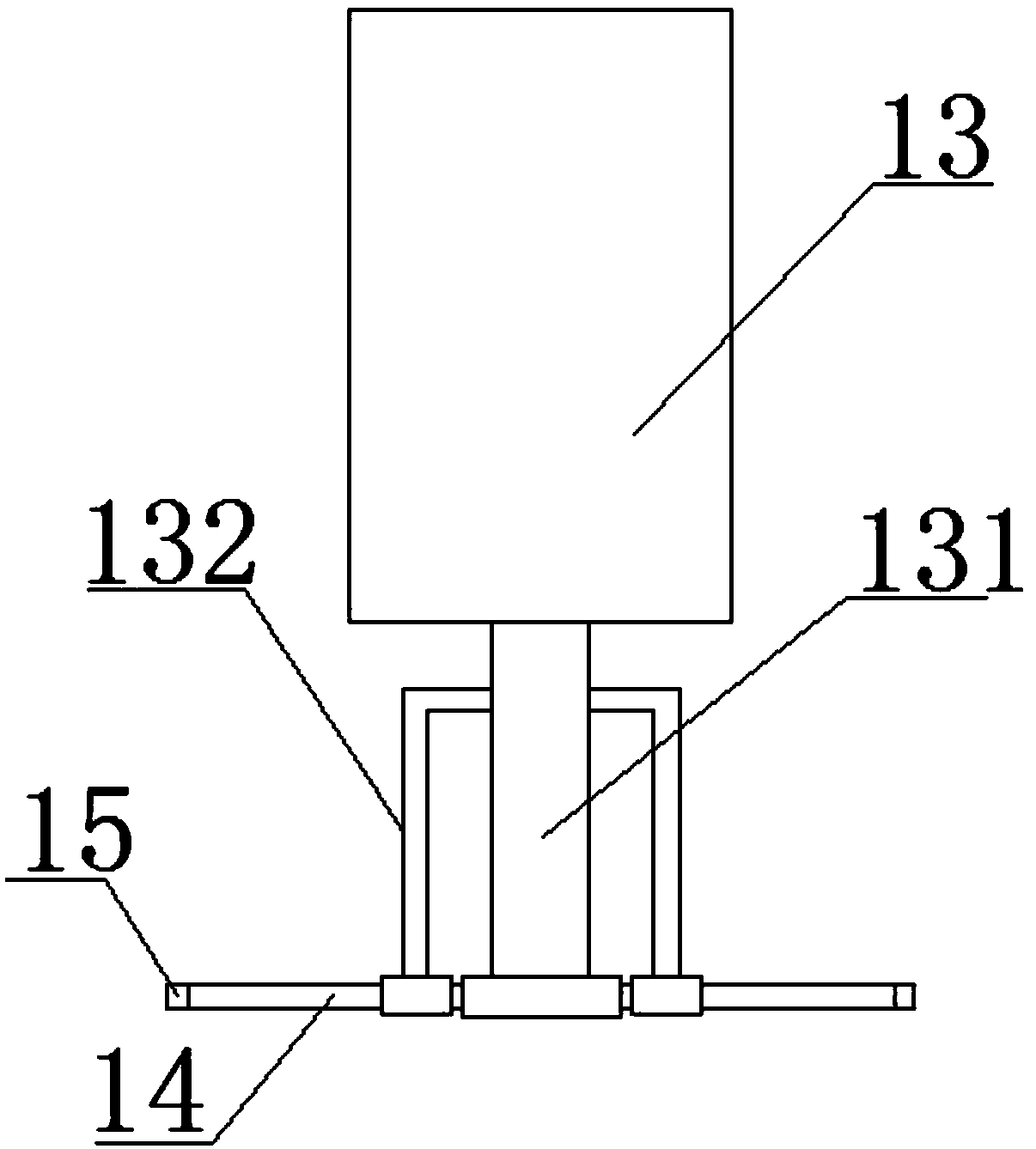

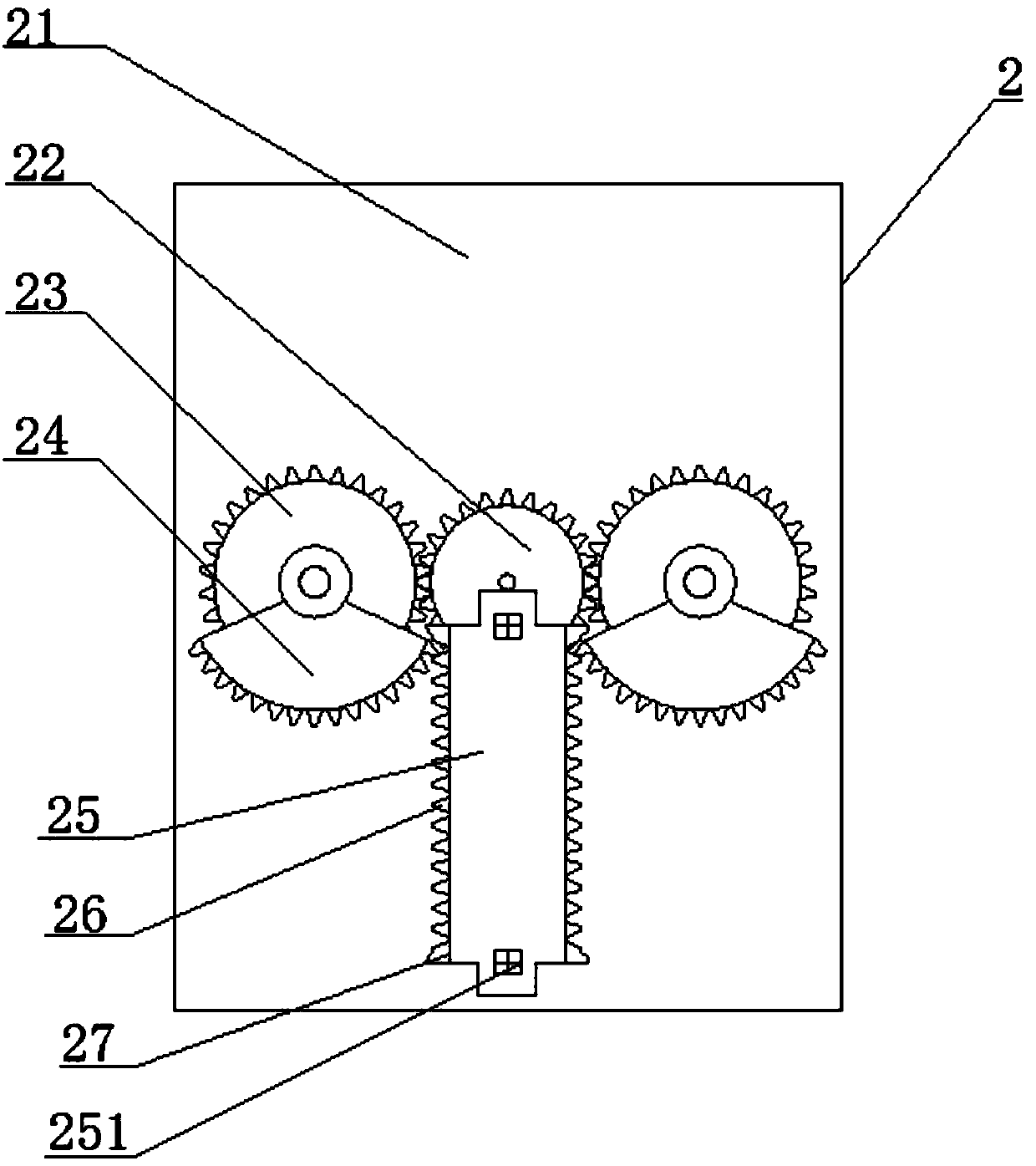

[0027] Such as Figure 1-Figure 3 As shown, a hydraulic jacking device that can move forward and backward is characterized in that it includes a jacking mechanism 1, and the jacking mechanism 1 includes a bottom connecting plate 18, and a rectangular bottom bracket 11 is arranged above the bottom connecting plate 18. , the bottom connecting plate 18 is connected with the front and rear displacement mechanism 2, the two long sides corresponding to the bottom bracket 11 are provided with chute 12, and a short side of the bottom bracket 11 is provided with a hydraulic cylinder 13, and the output of the hydraulic cylinder 13 The shaft 131 is connected with a drive link 14, the two ends of the drive link 14 are provided with a slide block 15, the slide block 15 is located in the chute 12 and can move along the length direction of the chute 12, the drive link 14 A lifting support 16 is connected to the top, and a lifting plate 17 is provided above the lifting support 16 .

Embodiment 2

[0029] On the basis of Embodiment 1, the lifting bracket 16 includes two sets of lifting assemblies, the lifting assembly includes a first connecting rod 161 and a second connecting rod 162, one end of the first connecting rod 161 is hinged to the driving connecting rod 14 , the other end of the first connecting rod 161 is hinged to the bottom of the lifting plate 17, one end of the second connecting rod 162 is hinged to the inner side of the bottom bracket 11, and the other end of the second connecting rod 162 is hinged to the bottom of the lifting plate 17, so The middle part of the first connecting rod 161 and the second connecting rod 162 is hinged.

Embodiment 3

[0031] On the basis of Embodiment 2, the lengths of the first connecting rod 161 and the second connecting rod 162 are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com