Pull-away test device for ball head of tailgate electric support bar

A technology of electric struts and experimental devices, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of complex metal processing technology, unstable pull-off force, high cost, etc., and achieve the effect of stable device, simple tooling and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings.

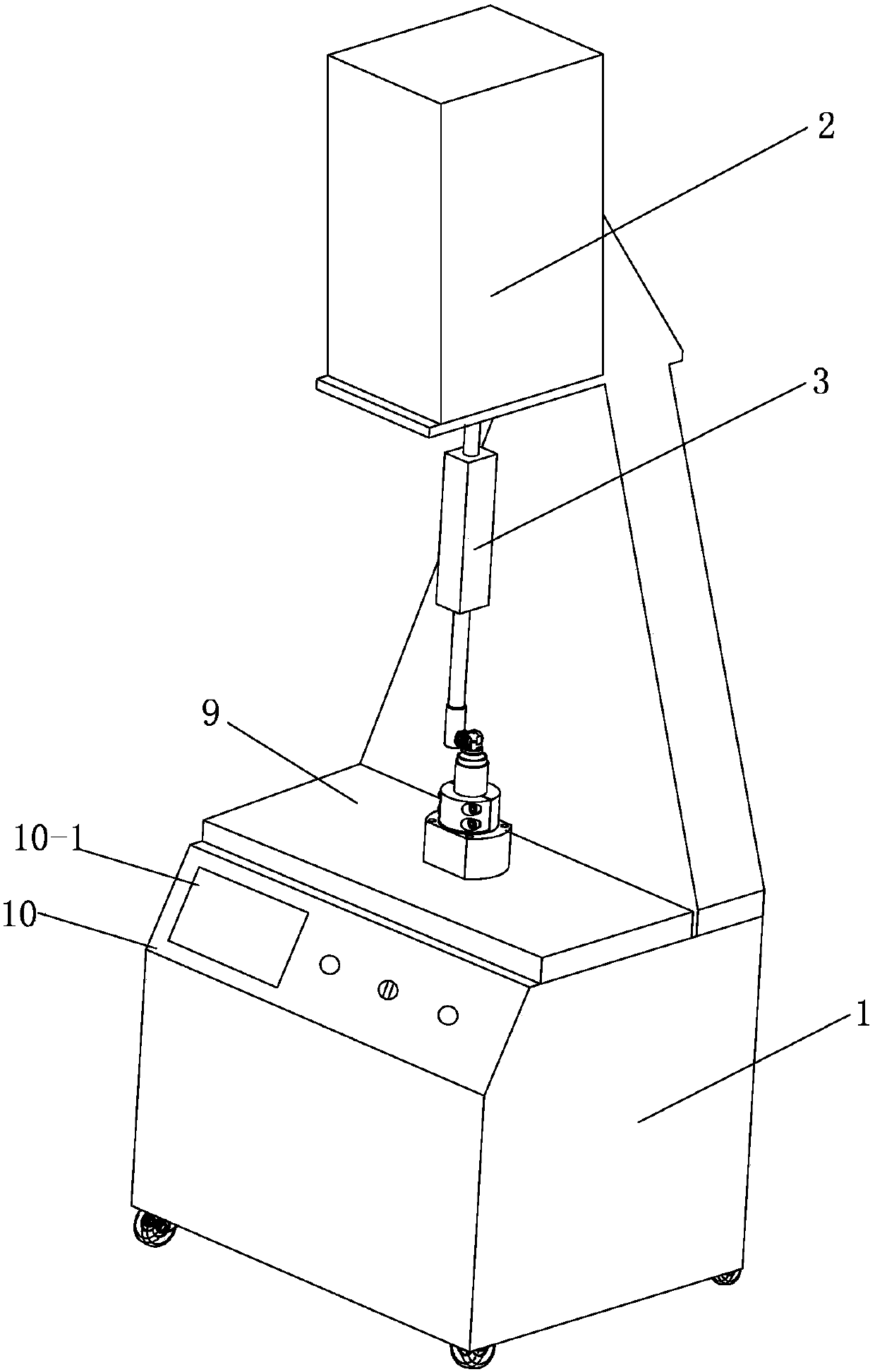

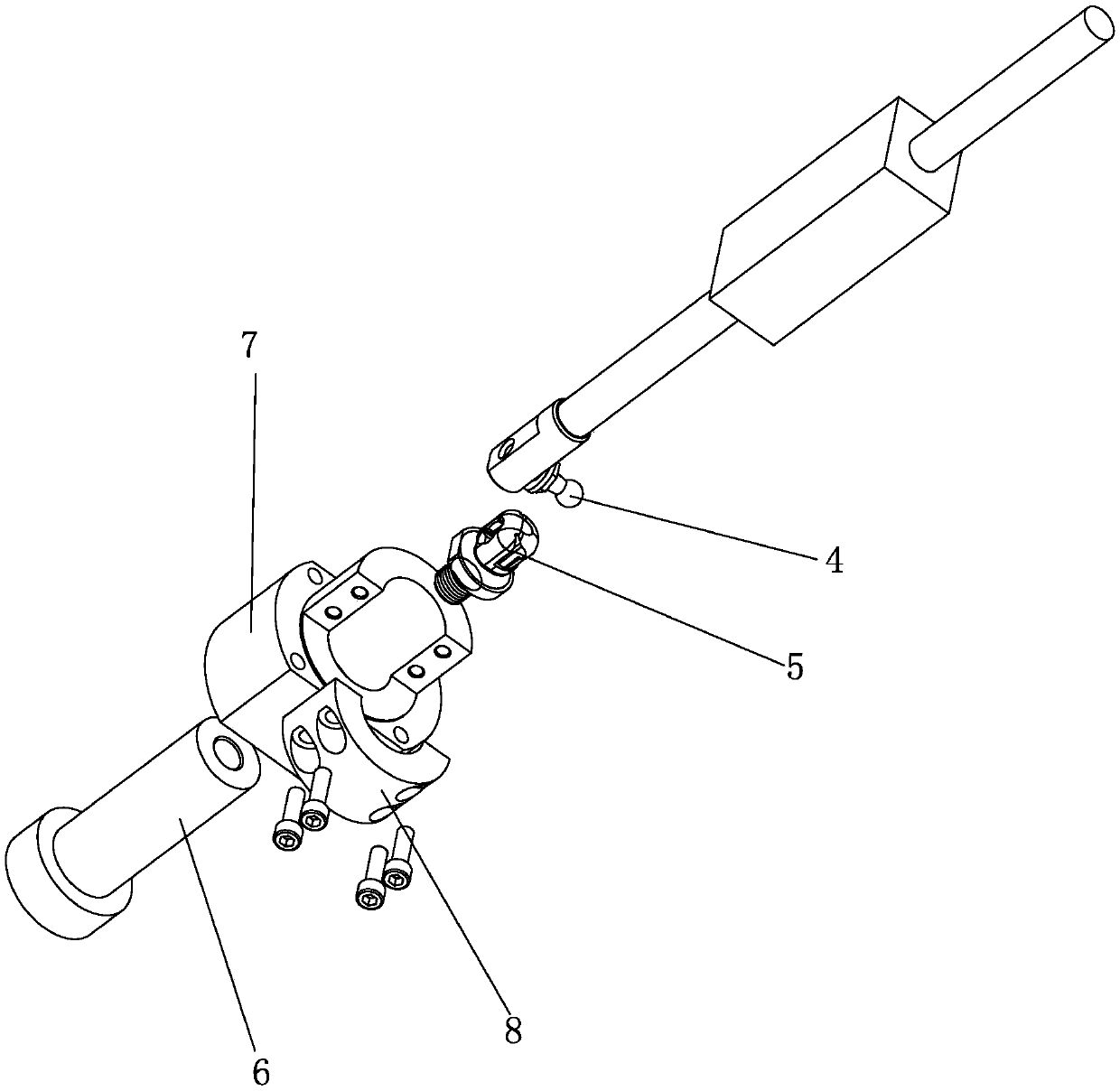

[0016] Such as figure 1 As shown, the tailgate electric strut ball head pull-off test device of the present invention includes a hydraulic machine base 1, a tooling base 9 is arranged on the working table of the hydraulic machine base 1, a lifting transmission device 2 is installed above the tooling base 9, and the lifting transmission device 2 The lifting drive end is connected to one end of the tension sensor 3, and the other end of the tension sensor 3 is connected to the center rod 4, and the center rod 4 and the ball head 5 are fixed by a retaining spring, so that the position of the center of the ball center rod 4 and the position of the center of the ball head 5 At the same point; the ball head 5 is threadedly connected to one end of the connecting rod 6, and the other end of the connecting rod 6 has a round platform, which is used to limit the upward displacement of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com