An elastic support unit for a wall casing assembly

A technology of elastic support and wall bushing, which is applied to electrical components and other directions, can solve the problems of easy damage and excessive pre-tension of elastic supports, and achieve the effect of reducing pre-tension and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

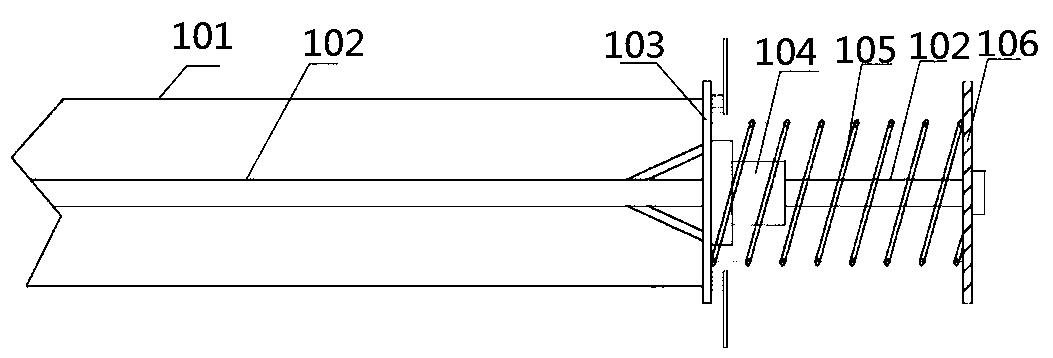

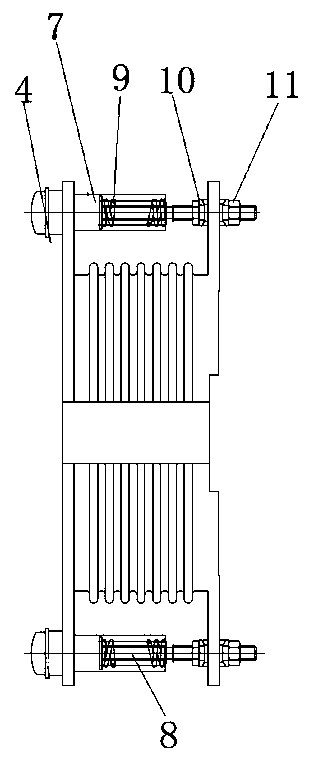

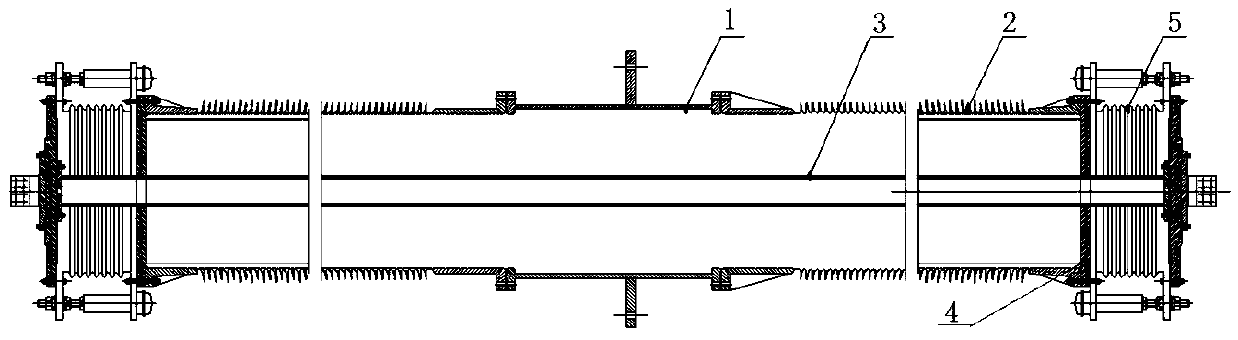

[0023] Specific embodiment one of the elastic support unit for the wall bushing assembly of the present invention, as Figure 2 to Figure 4 As shown, the wall bushing assembly includes an intermediate cylinder 1 and insulating sleeves 2 located at both ends of the intermediate cylinder 1 in the axial direction. The intermediate cylinder 1 and the insulating sleeve 2 together form a sleeve, and there is an insulating medium inside the sleeve. The housing chamber is provided with a hollow conductive rod 3 in the housing chamber, and a connecting flange 4 is sealed and fixed at the openings at both ends of the casing. The connecting flange 4 is provided with a conductive rod perforation, and one end of the conductive rod 3 is The conductive rod on the connecting flange 4 is pierced through the hole, and the pierced part forms the piercing section of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com