Hydraulic dual circuit system

A dual-loop, loop technology, applied in servo meter circuits, fluid pressure actuating devices, earth movers/shovels, etc., can solve the problem of too large measurement orifice size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

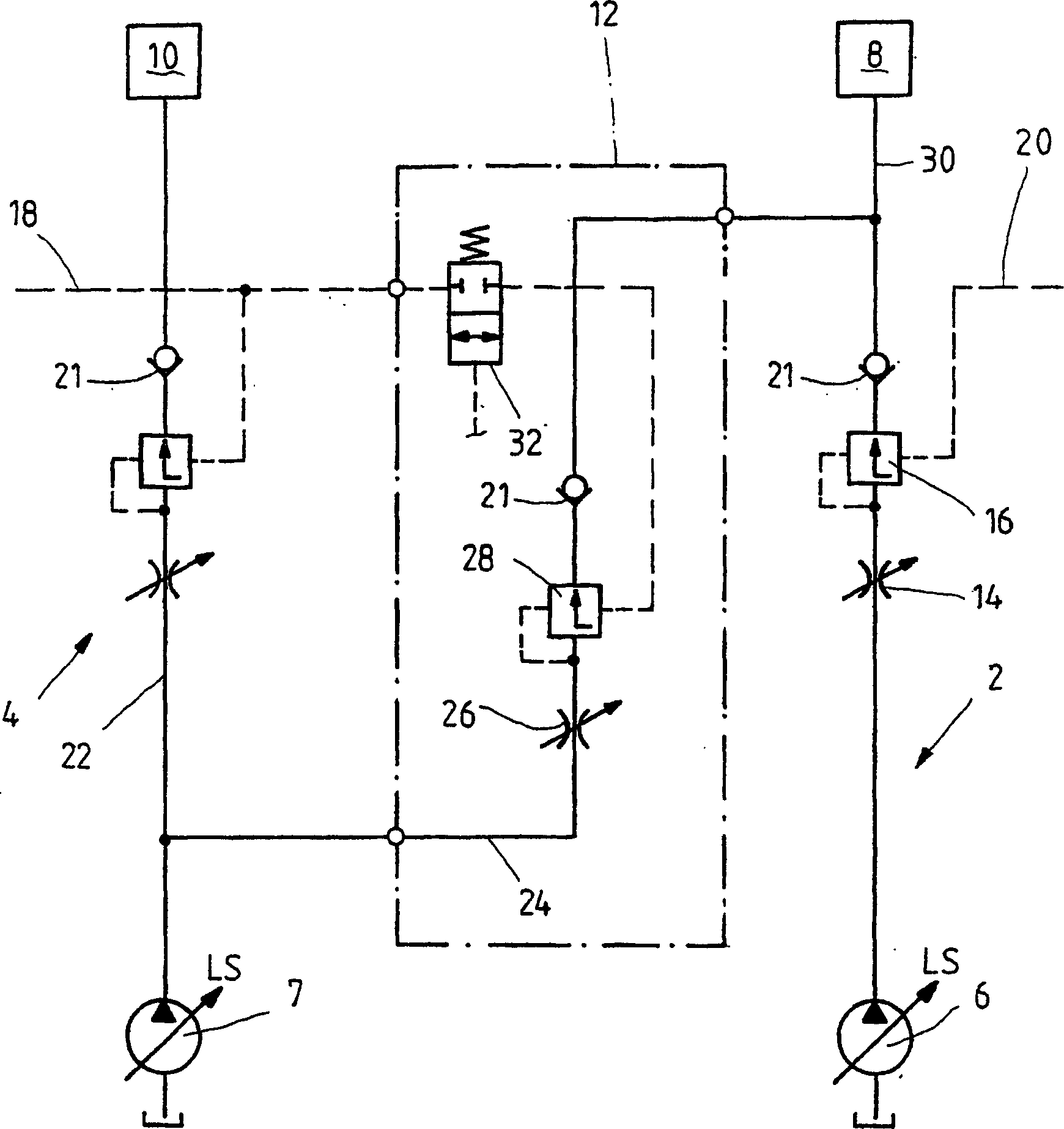

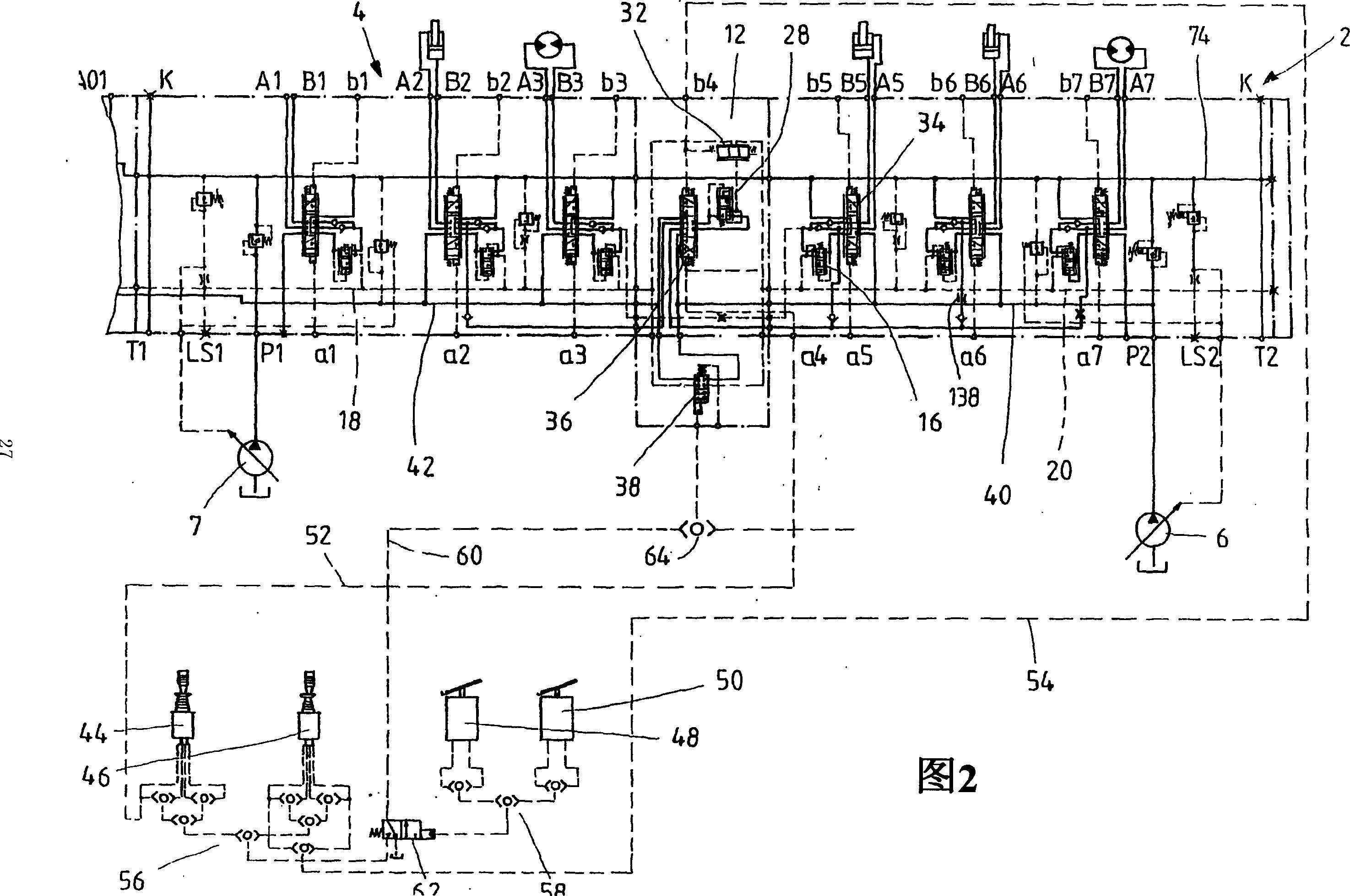

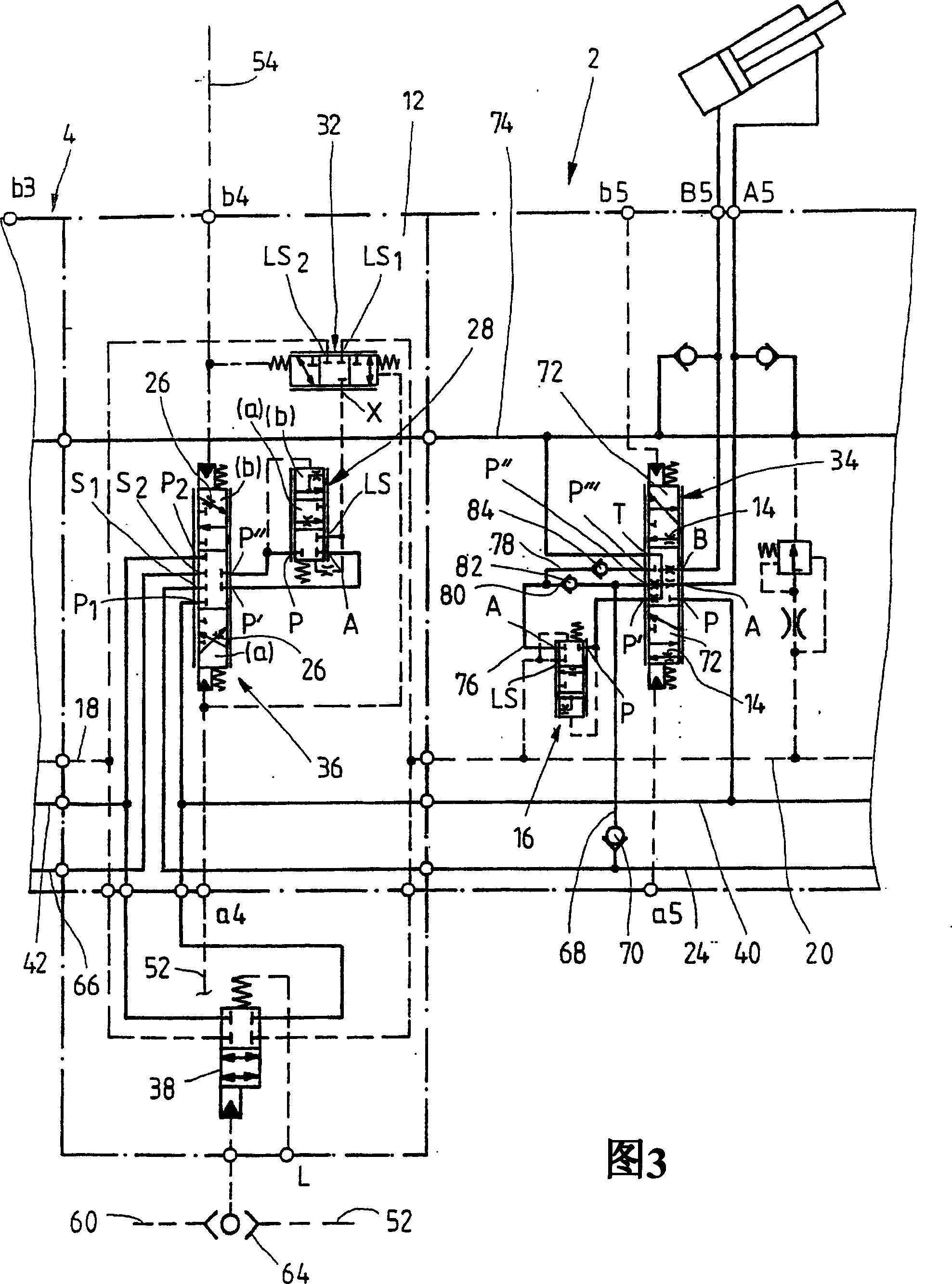

[0028] figure 1 A schematic diagram of an excavator control system is shown, which is designed as a dual-circuit system with two hydraulic circuits 2 , 4 . Consumers 8 , 10 of excavators such as the travel gear of the undercarriage with two caterpillar tracks, for example, or excavators such as the slewing mechanism, bucket handle, bucket or boom, can be controlled via two circuits equipment. The pressure medium supply of the two circuits 2 , 4 each takes place via auxiliary hydraulic pumps 6 , 7 which are preferably controlled as a function of the maximum load pressure in the respective circuit.

[0029] If the control consumer 8 requires more pressure medium than the assigned auxiliary hydraulic pump 6 can provide, the consumer 8 is operated undersaturated. To avoid such undersaturation, there is a combined valve arrangement 12 by which a predeterminable quantity of pressure medium can be delivered from the auxiliary hydraulic pump 7 to the consumer 8 .

[0030] In such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com