Non-Newtonian fluid anti-collision beam

A non-Newtonian fluid and anti-collision beam technology, applied in the field of anti-collision beams, can solve the problems of bulky and large anti-collision beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Preferred embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. Although preferred embodiments of the invention are shown in the drawings, it should be understood that the invention may be embodied in various forms and should not be limited to the embodiments set forth herein.

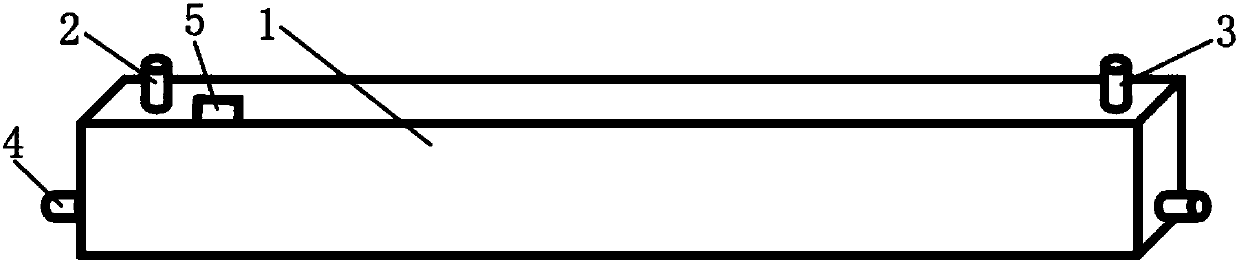

[0017] like figure 1 As shown, the present invention provides a non-Newtonian fluid anti-collision beam, including a metal shell 1, the inside of the metal shell 1 is filled with a non-Newtonian fluid, and the metal shell 1 is provided with a fluid inlet 3 and an exhaust hole 2. The exhaust hole 2 is located on the upper surface of the metal casing 1 .

[0018] The anti-collision beam also includes two fluid outlets 4 arranged on the side of the metal casing 1 .

[0019] The shape of the above-mentioned metal casing 1 is a cuboid.

[0020] The above-mentioned metal shell 1 is provided with an ellipsoidal cavity, the ellipsoida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com