Method for controlling shape steel tilting and stacking electromagnets

A control method and electromagnet technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of channel steel unstacking, affecting the channel steel stacking rhythm, and steel dropping, etc., to improve production. Efficiency and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

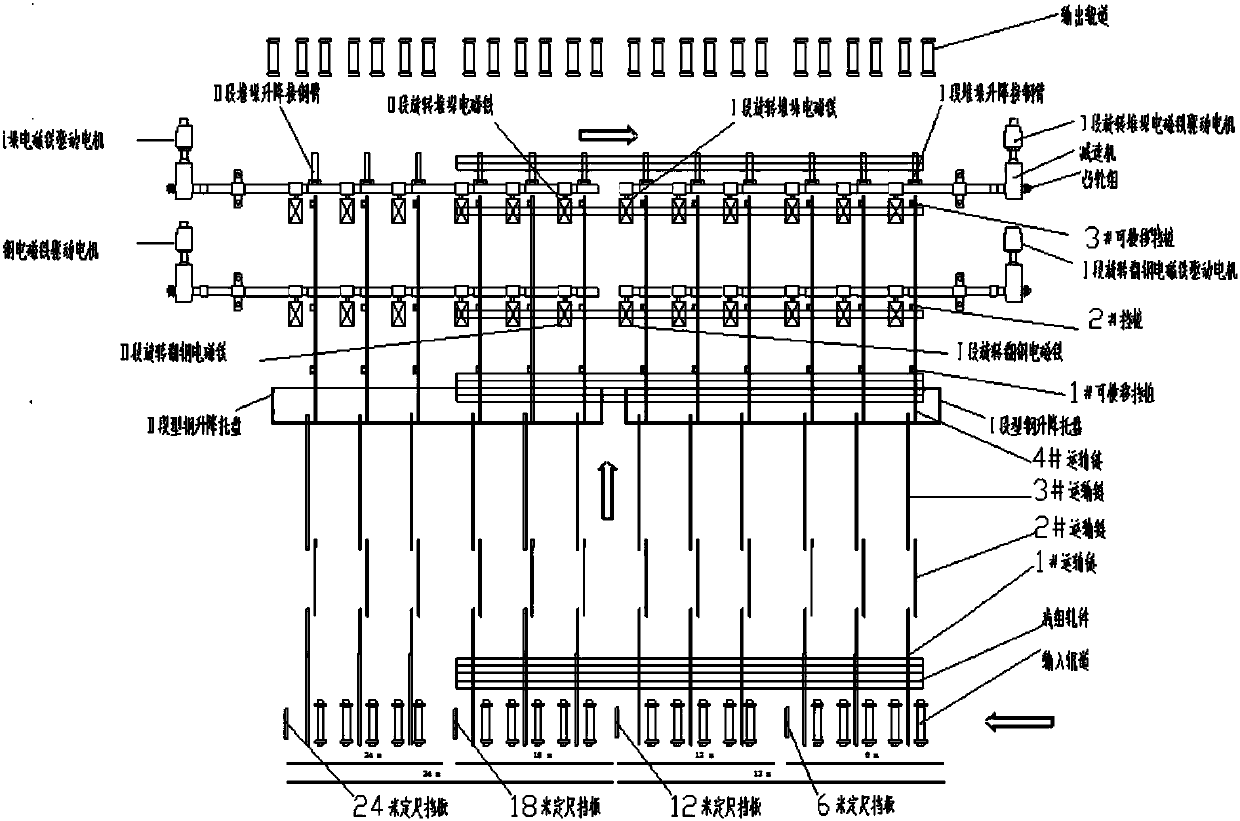

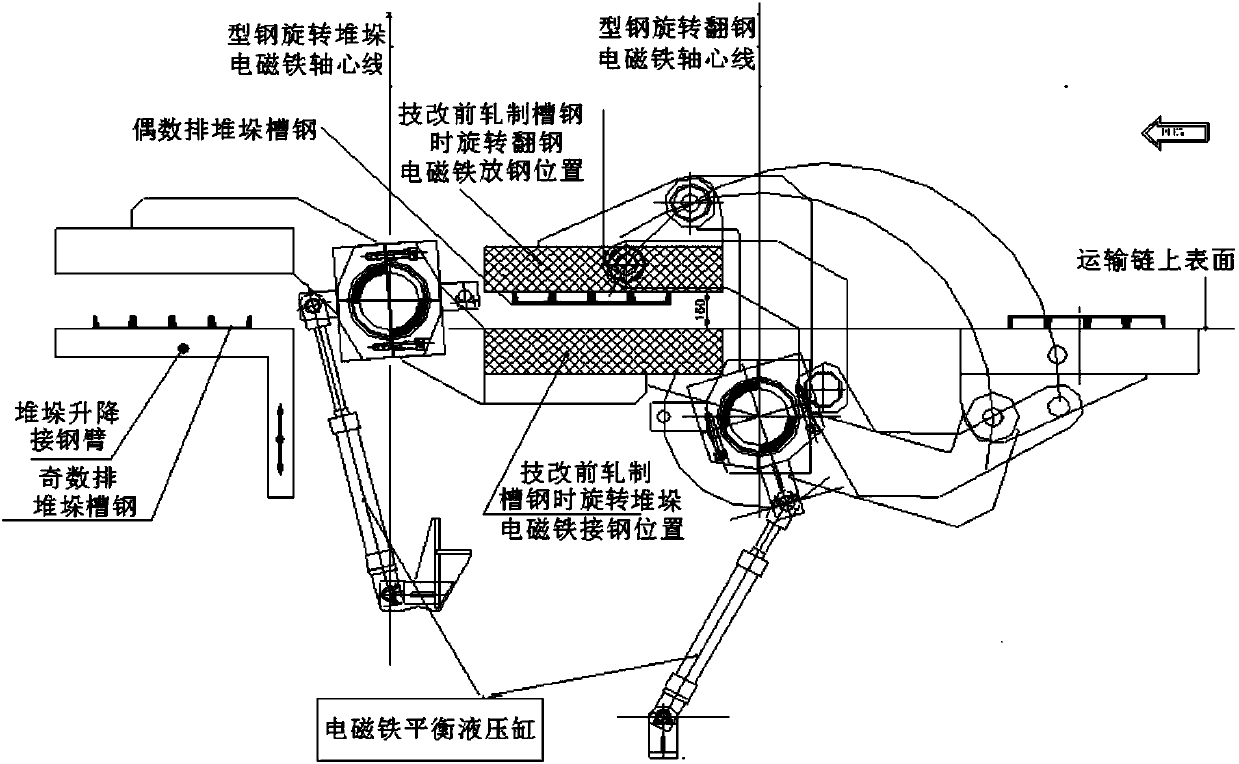

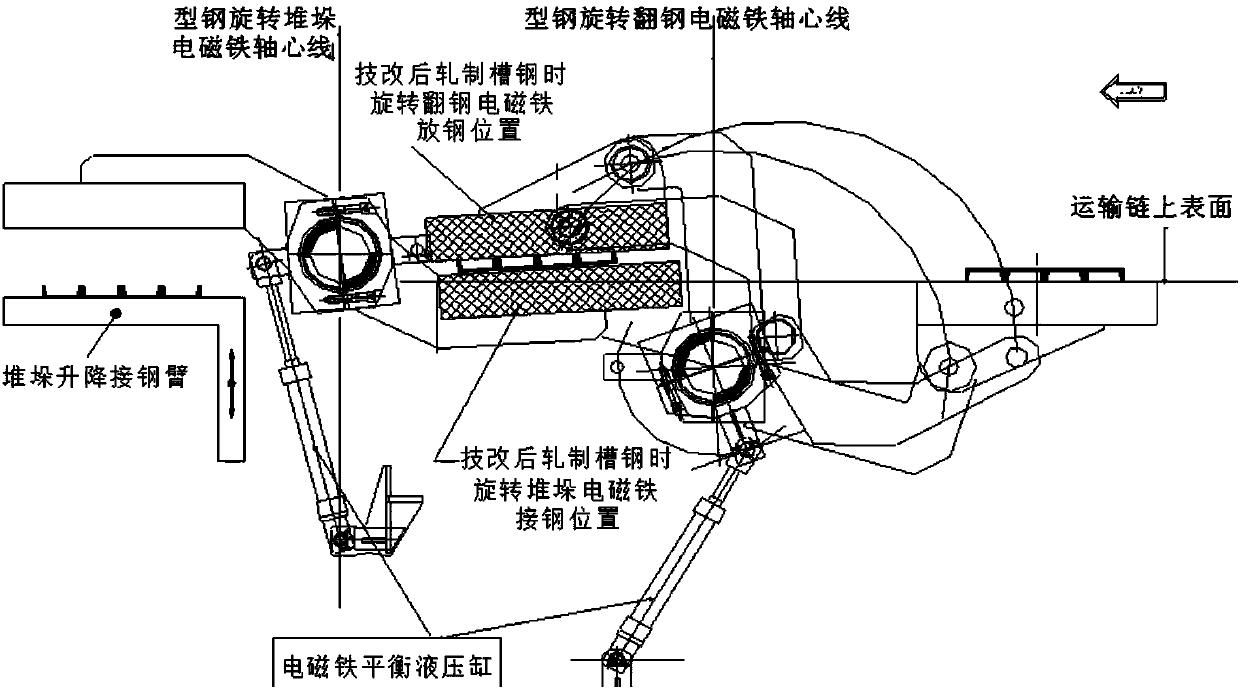

[0056] Such as image 3 The structure of the present invention represented is the arrangement of small H-shaped steel 24m stacking bed process equipment; When the legs of the steel are short and there are rows of channel steels, the channel steels on both sides of the row of channel steels are prone to the problem of destacking or steel dropping. The stacking electromagnet control method can thoroughly avoid the problems that occur when short legs are stacked in rows of channel steels.

[0057] In order to solve the problems existing in the prior art and overcome its defects, and realize the purpose of the invention to completely ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com