Wiper blade and windscreen wiper system

A technology of wiper blades and glass scrapers, used in transportation and packaging, vehicle cleaning, vehicle maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

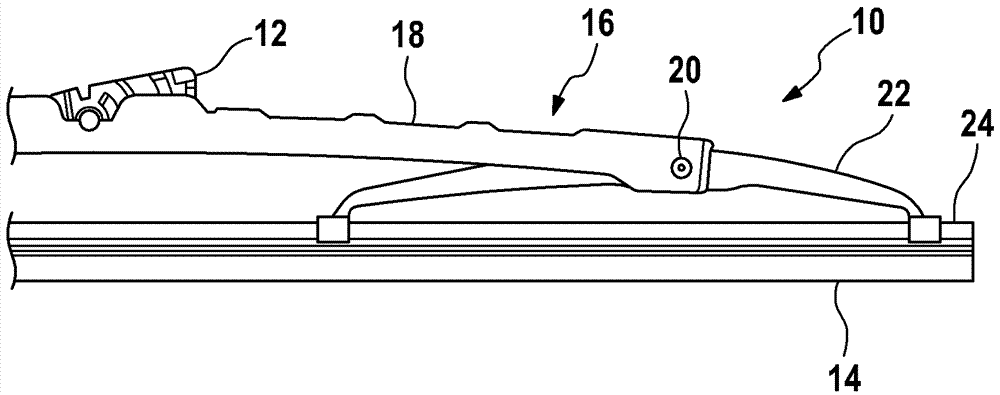

[0022] figure 1 A portion of wiper blade 10 is shown. The wiper blade 10 has a fastening element 12 for fastening the wiper blade 10 , a wiper lip 14 and a carrier 16 on which the wiper lip 14 is arranged. In the example shown, fastening element 12 is a fastening clip, wiper lip 14 is a rubber lip and carrier 16 has the conventional shape of a wiper blade carrier. This conventional carrier 14 has a center bracket 18 , a joint 20 , a jaw bracket 22 and a spring rail 24 . The center bracket 18 is pivotably connected via the joint 20 to the jaw bracket 22 , and the jaw bracket 22 itself carries the spring rail 24 . The wiper lip 14 extends in the longitudinal direction over the entire length of the spring rail 24 , so that when the wiper blade 10 wipes in the transverse direction on a surface, for example a windshield of a vehicle, , the wiper lip 14 slides over the surface and wipes off moisture accumulated in the form of droplets or dew there. As an alternative to the illus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com