Apparatus and method for communicatively coupling field devices in a process control system to a controller using a distributed marshalling architecture

A technology of process control system and field equipment, applied in the direction of general control system, control/regulation system, program control, etc., which can solve problems such as complex controllers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

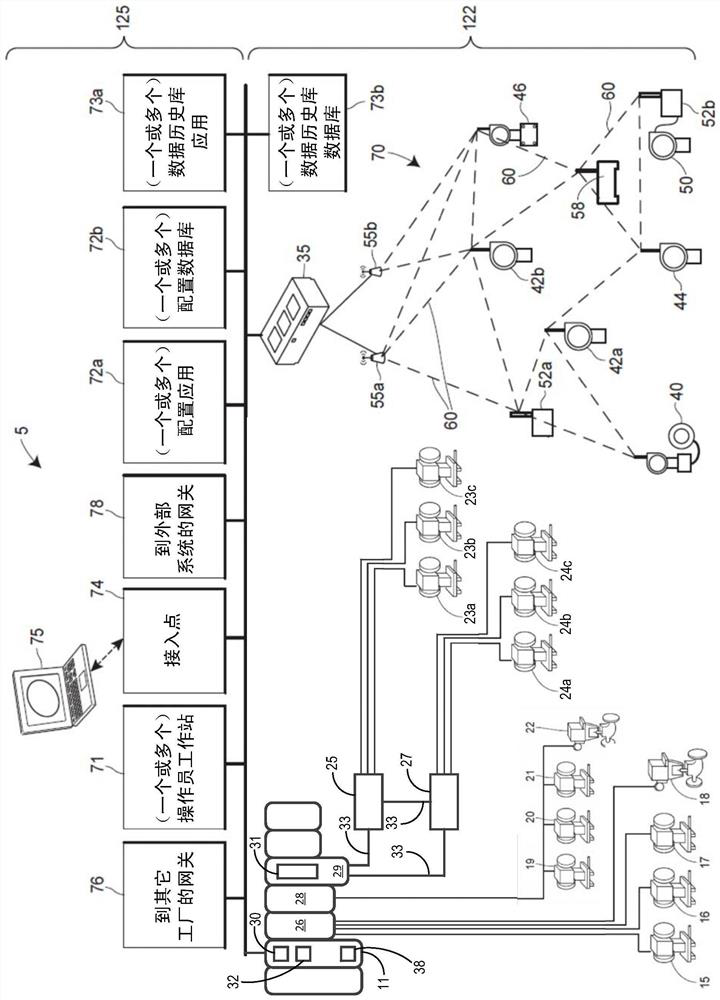

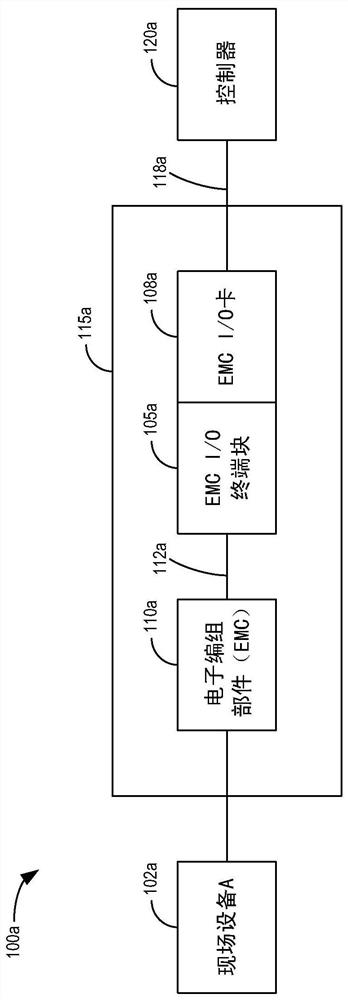

[0035] As discussed above, a process plant, process control system, or process control environment (which operates to control one or more industrial processes in real time when it is online) can utilize the novel techniques, systems, devices, components described herein during commissioning One or more of the , the apparatus and / or the method are communicatively connected. A process plant, when commissioned and operating online, includes one or more wired or wireless process control devices, components or elements that perform a physical function with a process control system to control one or more processes performed within the process plant. The process plant and / or process control system may include, for example, one or more wired communication networks and / or one or more wireless communication networks. Additionally, the process plant or control system may include centralized databases such as continuous, batch, asset management, historian, and other types of databases.

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap