Carton having shock-absorging carrying handle

A technology of cardboard boxes and handles, which is applied in the field of cardboard boxes and can solve problems such as increased production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] best practice

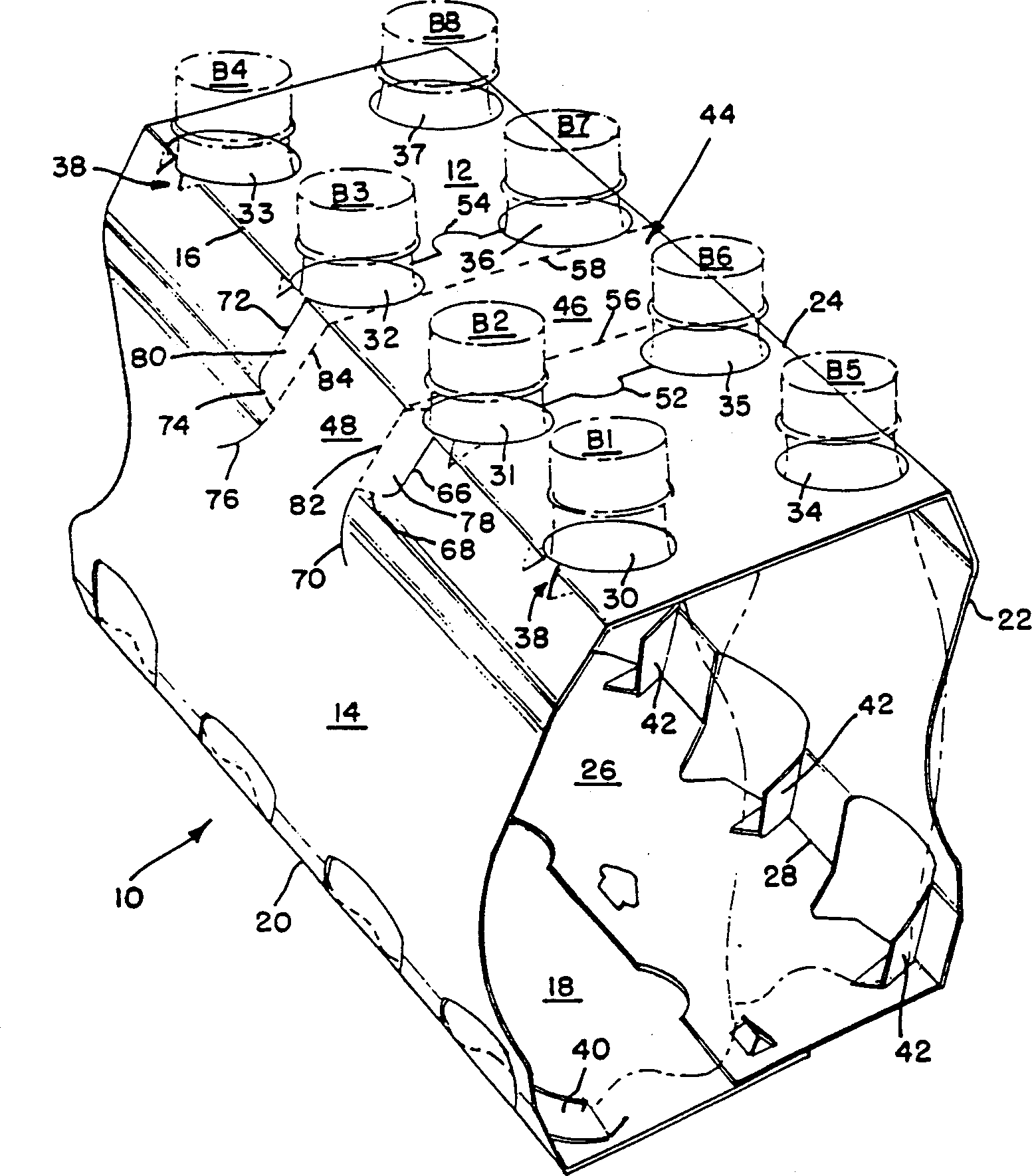

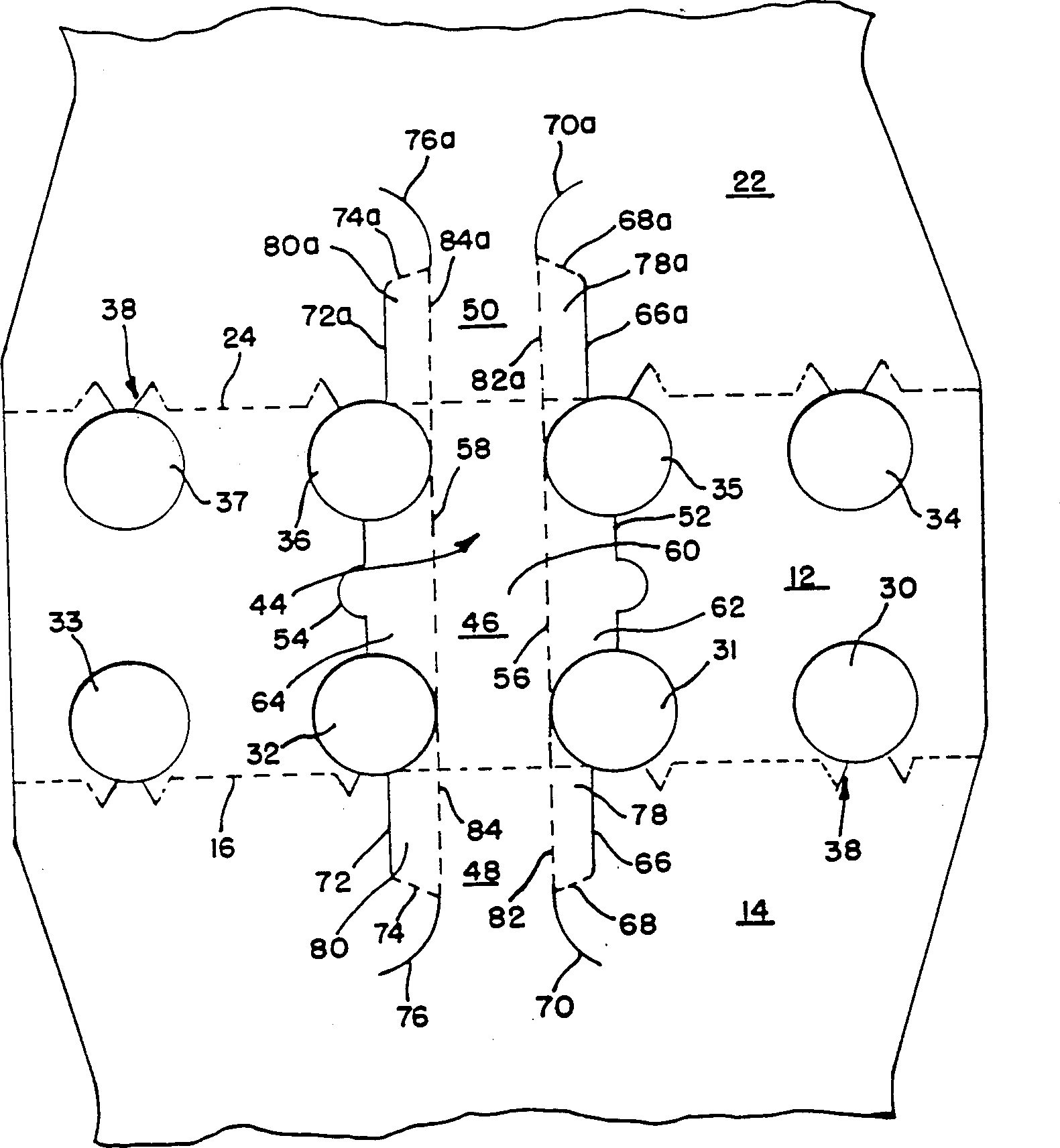

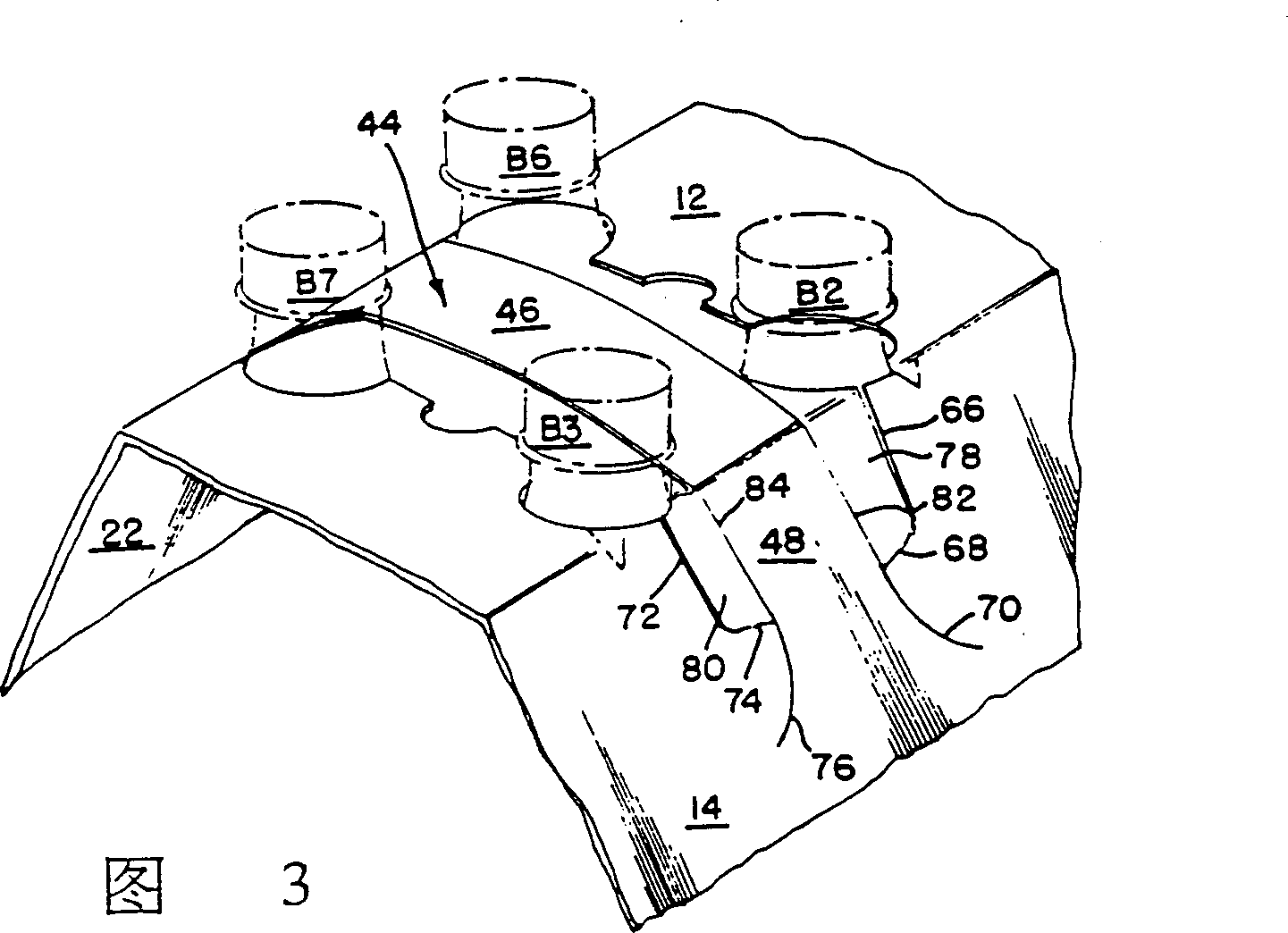

[0023] figure 1 A packaged carton 10 is shown, with a tubular opening structure, accommodating several bottles. figure 1 8 bottles B1-B8 are drawn with dotted lines, arranged in two rows, 4 bottles in each row, and they are arranged in the carton 10 in a vertical and parallel relationship to the longitudinal central axis.

[0024] The carton 10 includes a top panel 12 which is horizontally proximate the tops of the bottles B1-B8. Top plate 12 has several bottle neck receiving holes 30-37. The necks of the bottles B1-B8 are respectively placed in the holes 30-37 and protrude upwardly from the top plate 12, figure 1 clearly shown. A side panel 14 is joined to the top panel 12 by folding along fold line 16, and extends downwardly therefrom to be positioned adjacent the side walls of the bottles B1-B4. A floor strap 18 is foldably attached to the lower edge of side wall 14 along fold line 20 and extends generally horizontally beneath bottles B1-B4. A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com