Fluidized bed boiler material returning device

A technology of fluidized bed boiler and material return, which is applied in the field of thermoelectricity, can solve the problems of high cost of boiler reconstruction, achieve the effects of preventing ash accumulation, best return material effect, and optimized cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

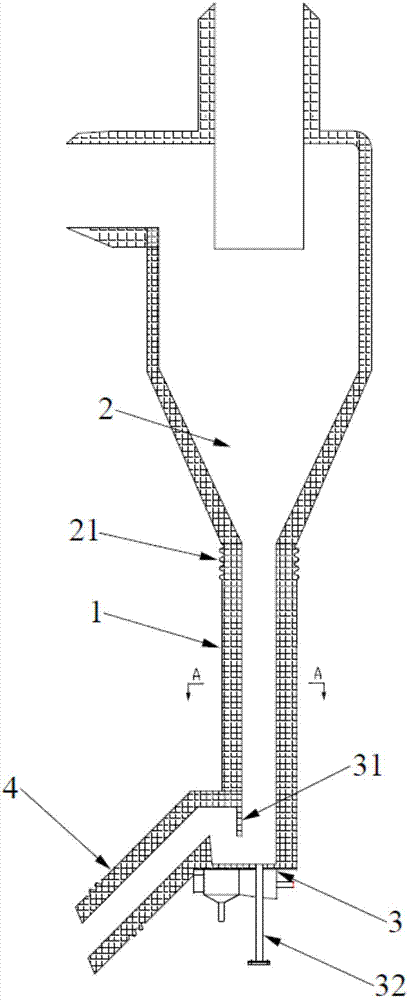

[0033] Such as figure 1 As shown, this embodiment provides a material return device for a fluidized bed boiler, including a separator 2 , a material return standpipe 1 , a material return device 3 and a material return inclined leg 4 connected in sequence. Part of the finer particles in the coal fired in the fluidized bed boiler enter the separator 2 from the outlet of the furnace (not shown in the figure), and after separation, most of the particles are separated and pass through the lower exhaust port (that is, the separator 2 bottom outlet) enters the return riser 1, and then is sent back to the furnace after passing through the return device 3 and the return inclined leg 4. Part of the extremely fine material particles fly out from the upper part of the separator 2, and enter the tail flue (not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com