Improved water separating body with clamping device

A technology of clamping device and water dividing body, which can be used in water supply devices, indoor sanitary pipeline devices, buildings, etc., and can solve problems such as limited space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

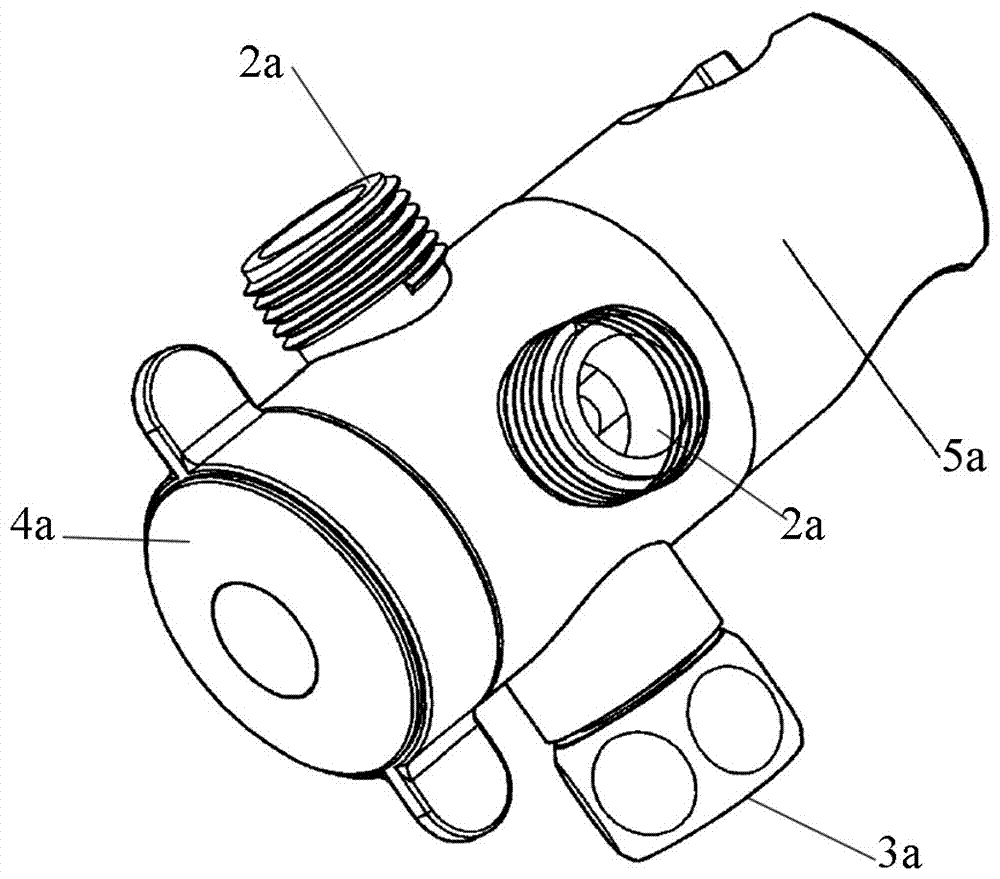

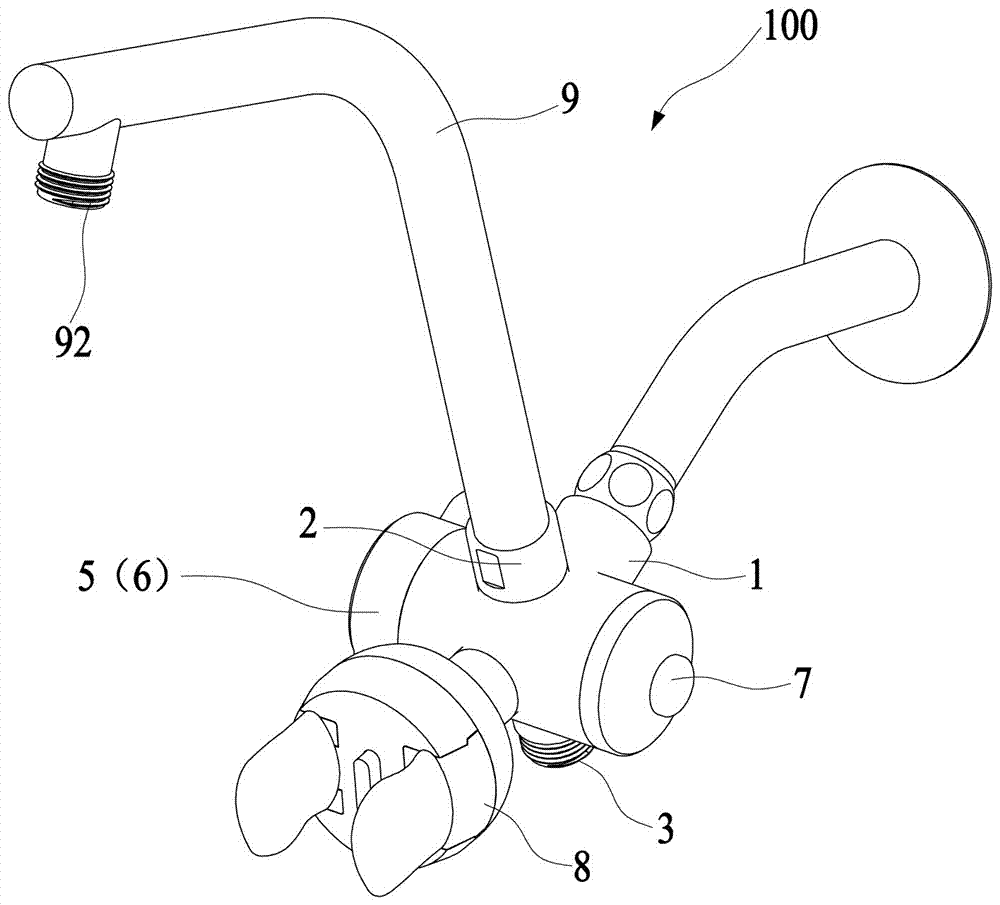

[0039] An improved water diversion body 100 with a clamping device 8, the water diversion body 100 is provided with a water inlet 1 and several water outlets, this embodiment has two water outlets, respectively the first water outlet 2 and the second water outlet The water outlet 3, the water diversion body 100 has a cylindrical body, the water inlet 1, the first water outlet 2 and the second water outlet 3 are all arranged at the radial end of the cylindrical body, and the The valve core 4 that controls the water inlet 1 to selectively connect / disconnect the first water outlet 2 and the second water outlet 3 is placed in a cylindrical body, and the actuator 5 that is externally connected to the valve core 4 is arranged on a circle. At one of the axial ends of the cylindrical body, the actuator 5 used in this implementation realizes the change of the switching angle of the valve core 4 by rotating the valve core 4 through the switching handle 6. Of course, the valve can also be...

no. 2 example

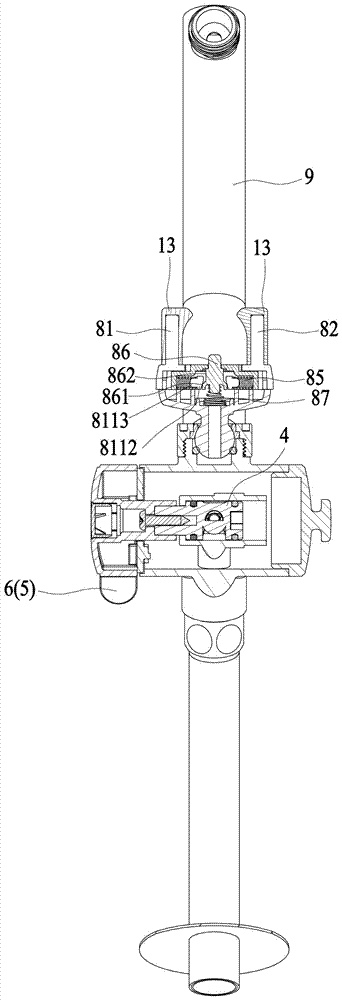

[0046] The structure of the second embodiment of the water diversion body 100 is basically the same as that of the first embodiment, except that there is a difference in the setting of the clamping device 8, specifically: it also includes a second clamping block 10 and a third spring 11; The end surface of the housing 83 is provided with a hollow portion 833, and the second clamping block 10 is flat, and the bottoms of both sides facing the left clamping arm 81 and the right clamping arm 82 are respectively provided with guiding slopes inclined from top to bottom to the outside. 101, the second clamping block 10 is placed in the hollow part 833 of the housing 83 from the inside to the outside and protrudes outward; The middle and lower part of one side of 10 forms a matching inclined surface 8114 that cooperates with the guiding inclined surface 101; the third spring 11 is located between the fixing seat 84 and the second clamping block 10; in the initial state, the left clampi...

no. 3 example

[0048] Such as Figure 10 As shown, the present invention also discloses a unilaterally movable clamping arm scheme, that is, assuming that the left clamping arm 81 is movable and the right clamping arm 82 is fixed, the end face of the shell 83 of this scheme does not need to be hollowed out, and the setting of the clamping block is cancelled. A dividing plate 834 is added in the inner side of the shell 83; a gap 831 is also required on the movable side of the housing, and a spacer 832 with a hollow cavity is provided at the gap 831; the longitudinal section of the left clamp arm 81 is L-shaped, and There is a connecting seat 811 at the bottom, and the connecting seat 811 is surrounded by two side plates 8111 and a front baffle plate 8112 to form a cavity A. Slide in as a guide positioning surface, and put the limit block 832 in its cavity A, one end of the first spring 85 is against the inner wall of the front baffle plate 8112 of the left clamp arm 81, and the other end is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com