Tubular implant device for preventing electric pole from being frozen to be bulged and tilting, manufacturing method thereof and rod standing method based on tubular implant device

A technology for implanting devices and electric poles, which is applied in the field of electric pole foundations, can solve problems such as the reduction of power supply reliability, and achieve the effect of long safe operation time and saving maintenance funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

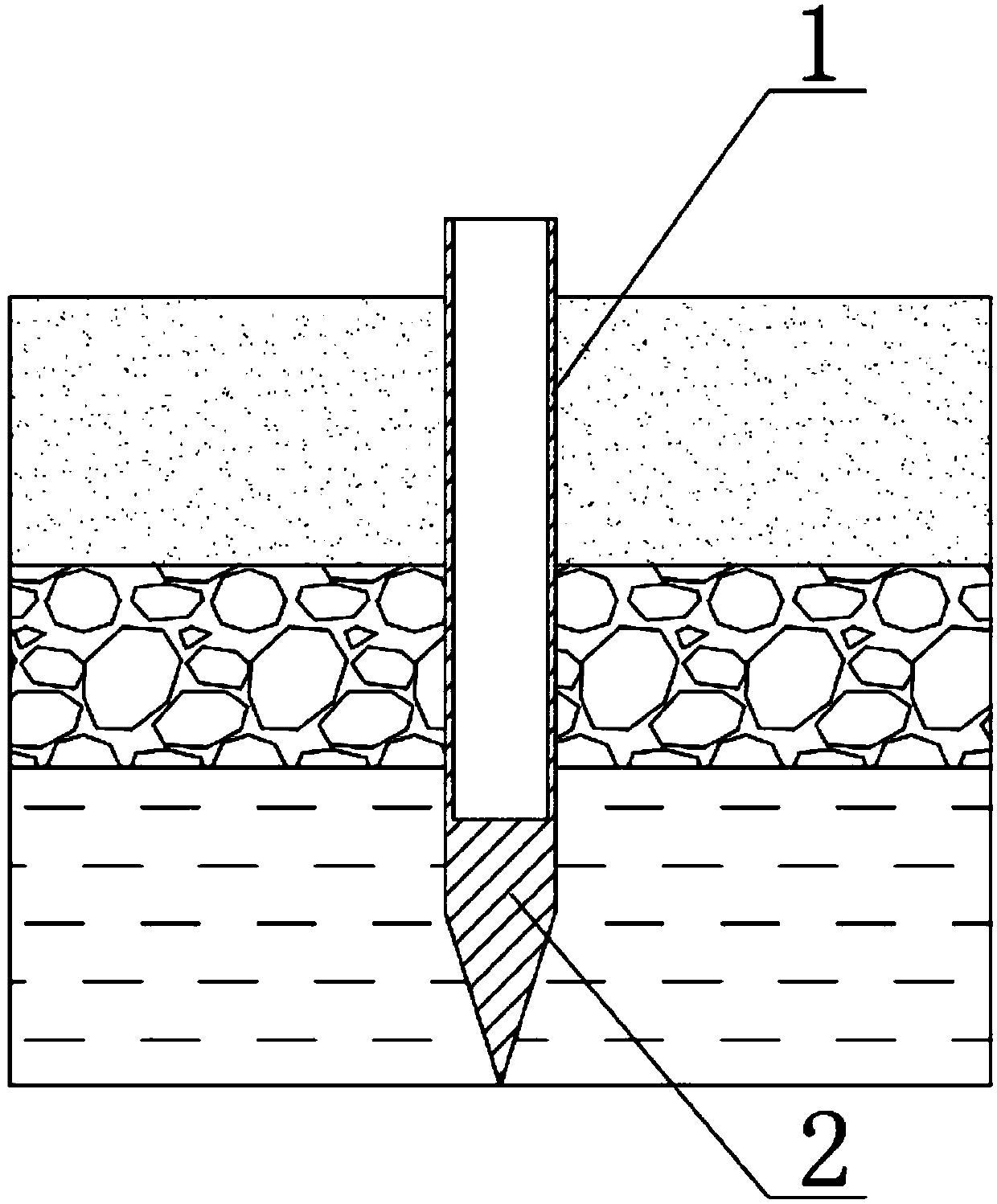

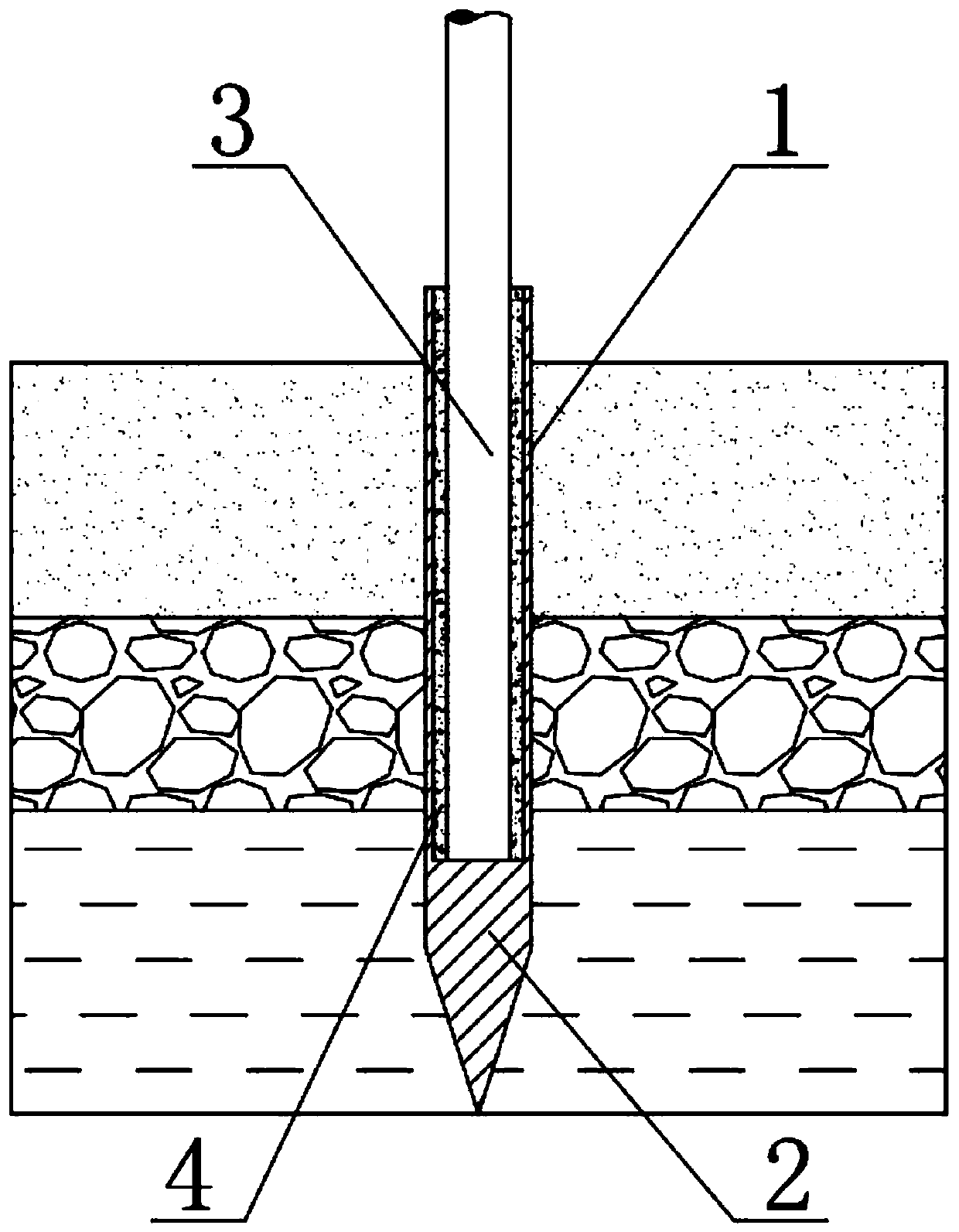

[0019] A tubular implant device for preventing the inclination of the electric pole freezing drum, comprising a casing 1 and a tapered part 2, the tapered part 2 is coaxially fixed on the bottom of the casing 1, and the tubular implant for preventing the inclination of the electric pole freezing drum The lowest point of the entry device is set at 2.8m~3.3m below the ground surface.

[0020] In this specific embodiment, the casing 1 and the tapered portion 2 are integrally provided. The tubular implant device for preventing the tilting of the pole freezing drum should be located 1.0m to 1.5m below the permafrost layer, and the distance below the ground surface is determined according to the thickness of the permafrost layer. m, so the lowest point of the device is located at a depth of 2.8m to 3.3m below the surface.

specific Embodiment approach 2

[0021] like figure 1 As shown, the difference between the second embodiment and the first embodiment is that the bottom surface of the tapered portion 2 is greater than or equal to the cross section of the sleeve 1 . The purpose of setting the tapered part 2 is to make use of the shape characteristics of the tapered part 2, so that the whole device can be easily driven into the ground below the surface. Therefore, the bottom surface of the tapered part 2 is required to be greater than or equal to the cross section of the casing 1. If If it is smaller than that, the effect will not be achieved, and even the casing 1 may be damaged.

specific Embodiment approach 3

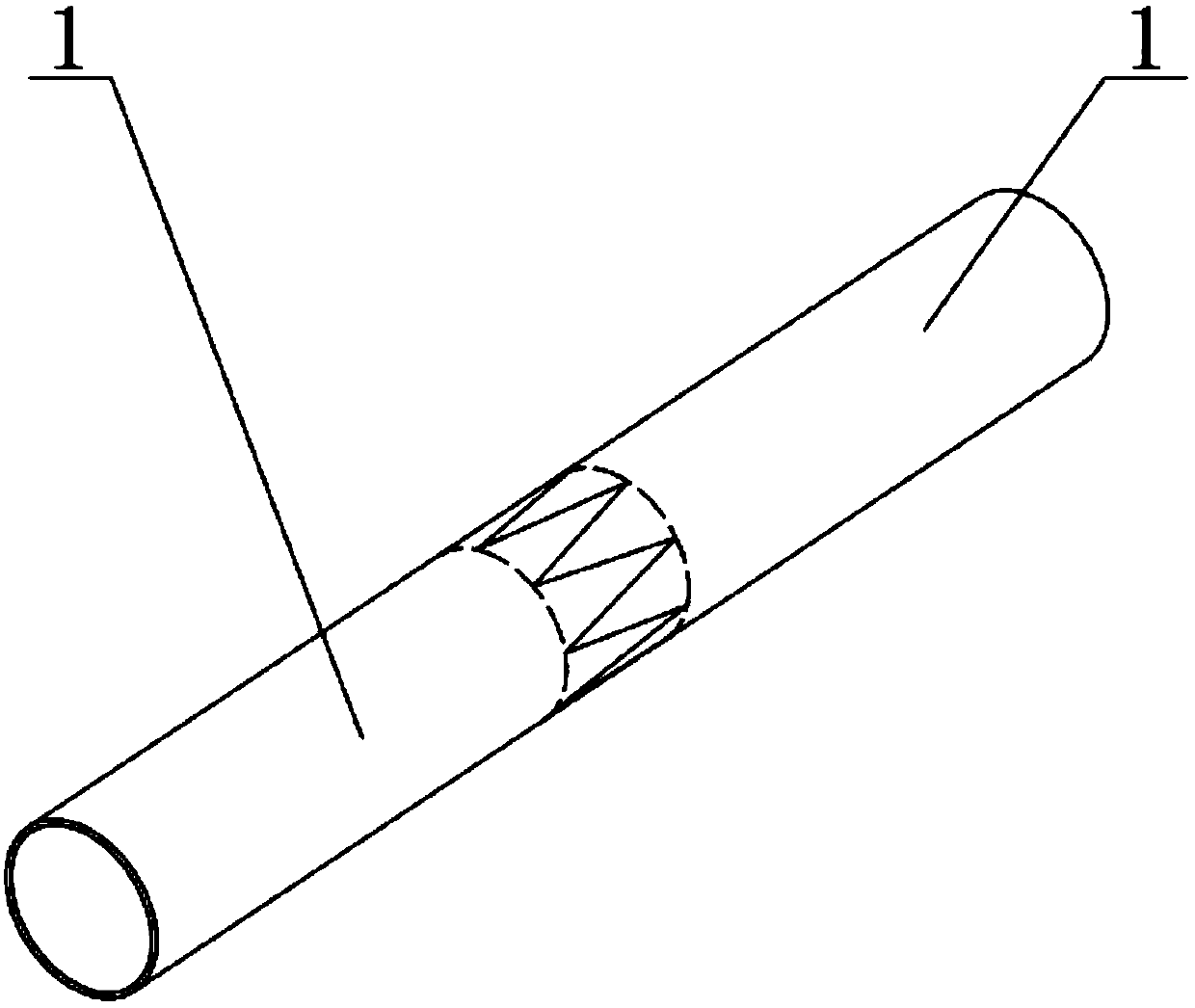

[0022] like figure 1 As shown, the wall thickness of the casing 1 is 4mm-6mm, the inner diameter is 230mm-500mm, and the height is 2.5m-2.8m; the height of the tapered part 2 is 0.6m-1.0m.

[0023] The above parameters are preferably casing 1 with a wall thickness of 5mm and a height of 2.65m. The electric pole adopts the concrete electric pole specification stipulated by the current national standard. Therefore, the inner diameter of the casing 1 is added to the diameter of the electric pole by 100mm, and the height of the tapered part 2 It is 0.65m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com