A kind of l-shaped nozzle mold

A nozzle and mold technology, which is applied in the field of L-shaped nozzle molds, can solve the problems of small travel space, inability to design and control the tensile deformation and tearing of bellows, and achieve the effect of improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

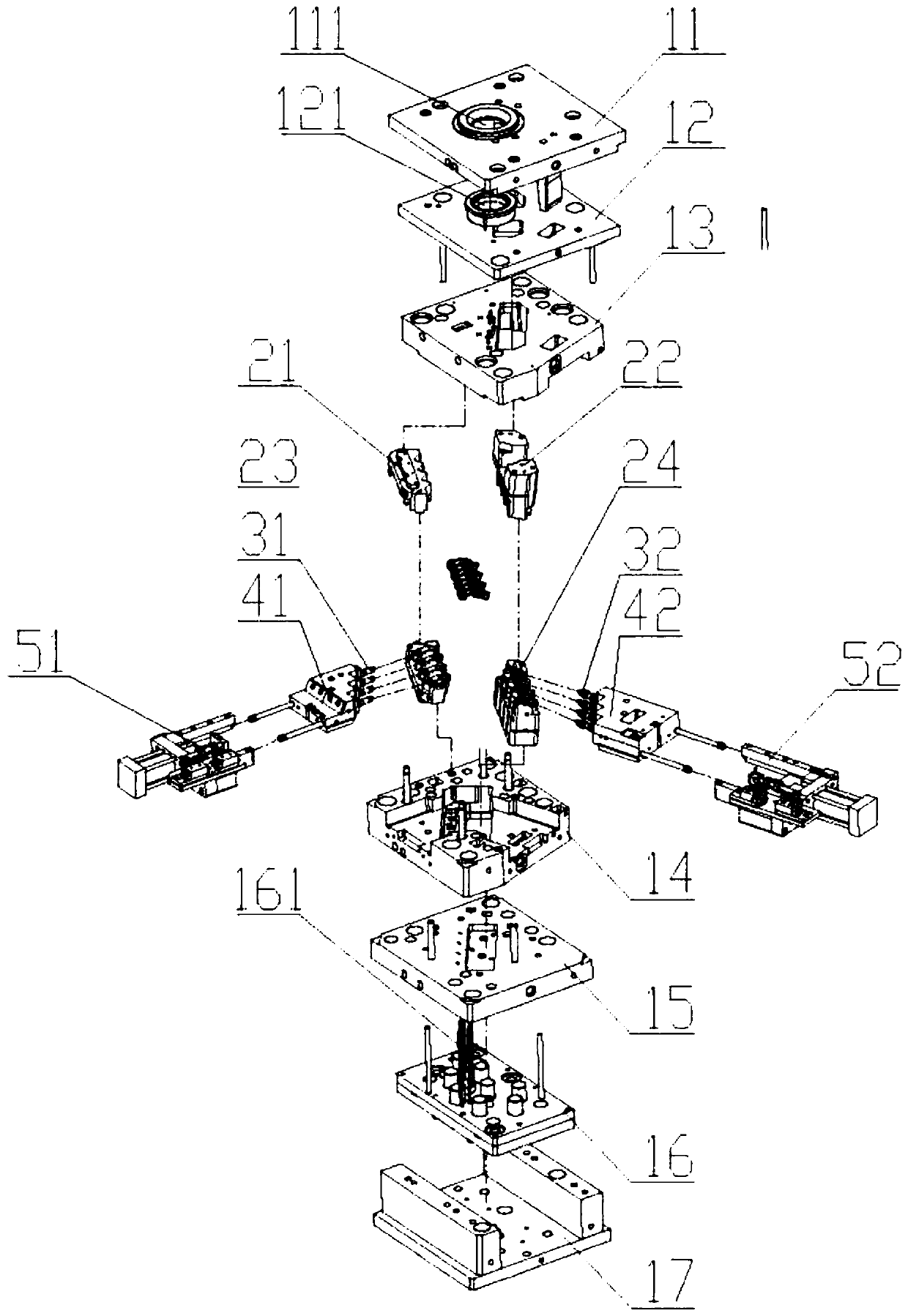

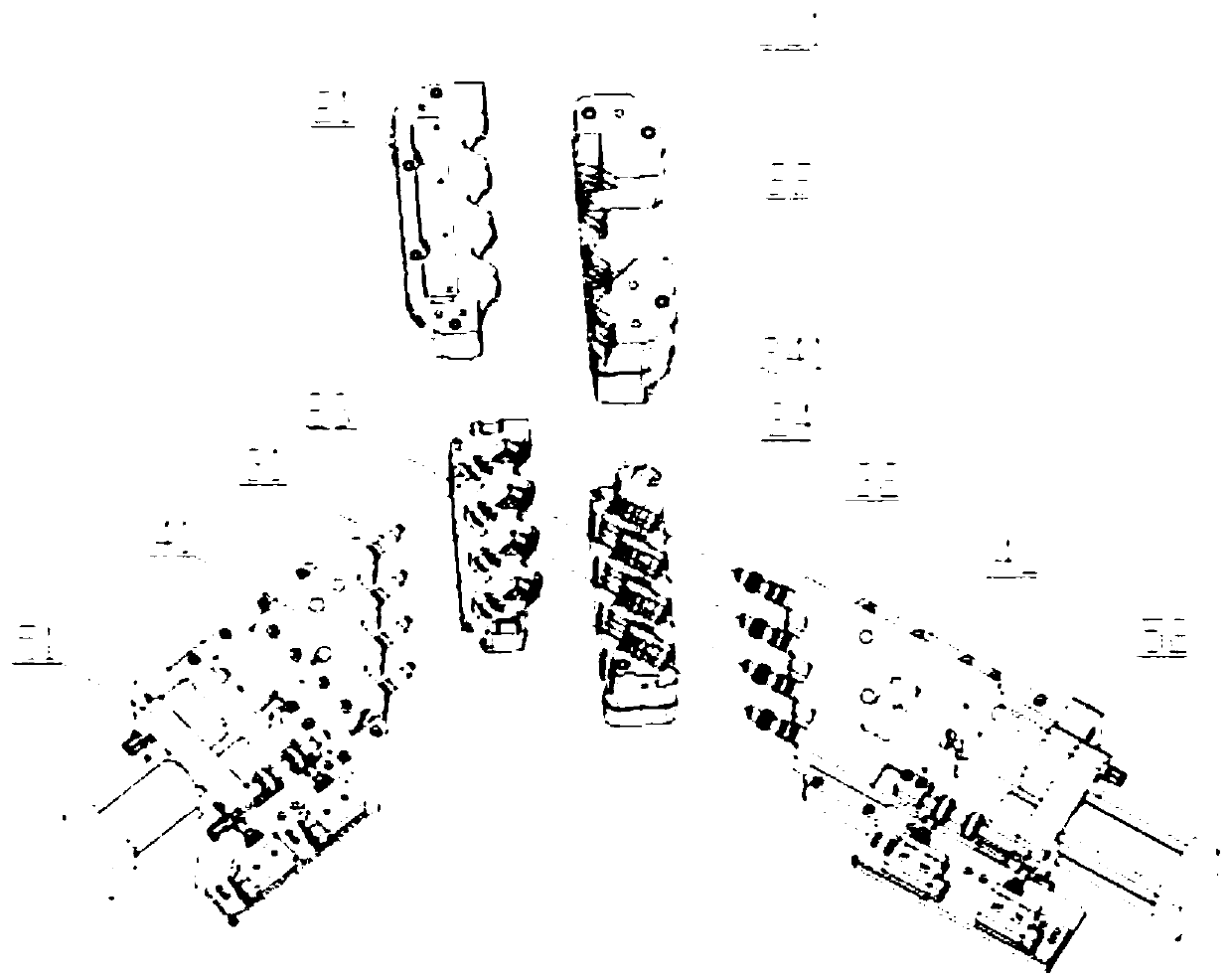

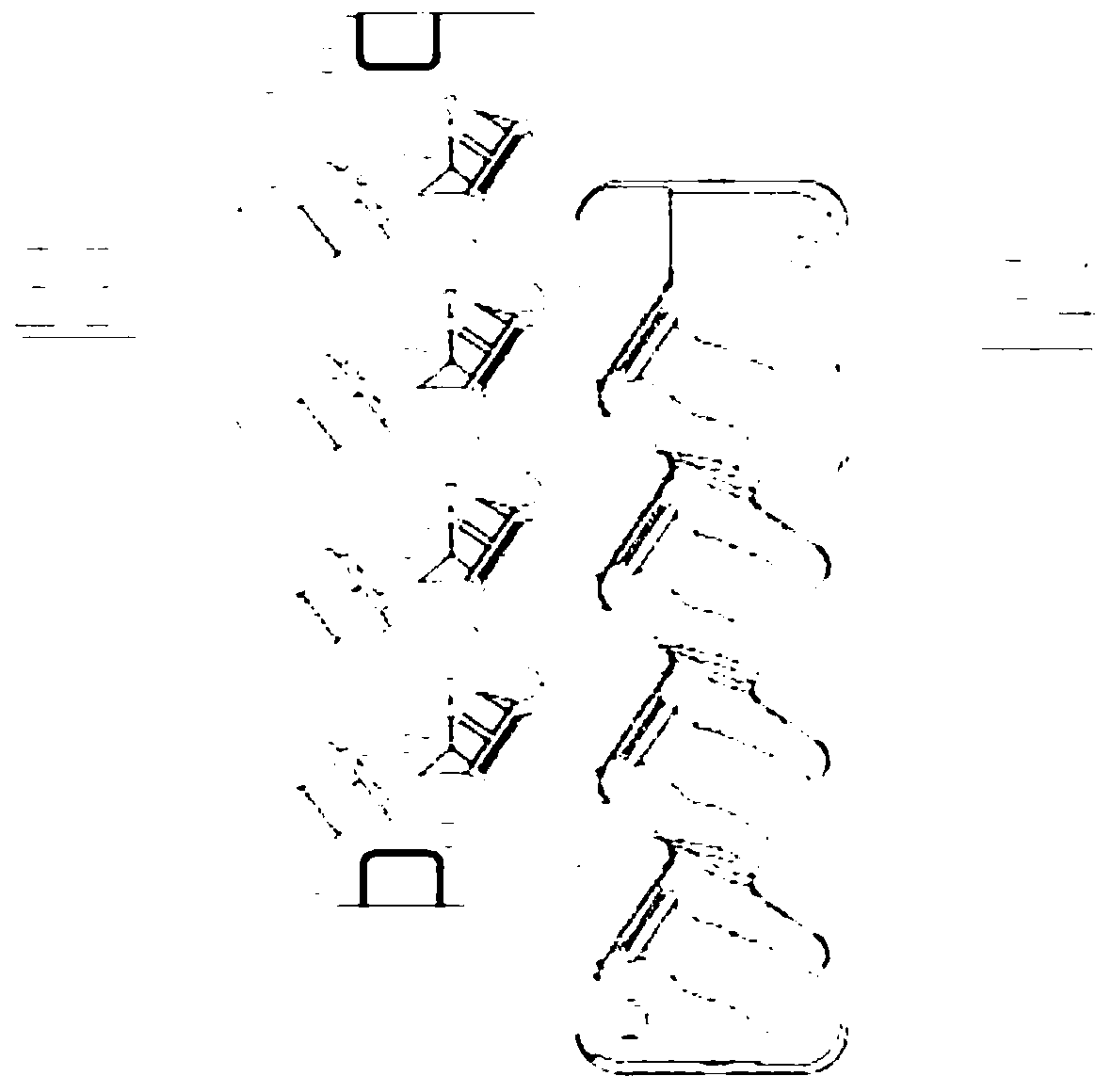

[0030] refer to Figure 1-3 , a kind of L-type nozzle mold that the present invention proposes, comprises; Panel 11, nozzle push plate 12, front template 13, push plate 14, rear template 15, thimble panel 16, square iron, bottom plate 17, inner mold 2, mold Core 3, slider 4, cylinder 5;

[0031] The panel 11 is provided with a main channel 111, and the nozzle push plate 12 is provided with a gate 121. The panel 11, the nozzle push plate 12 and the front formwork 13 are sequentially abutted against each other and installed and connected. The panel 11, the nozzle push plate 12 and the front formwork 13 can move along the direction of the gate 121; the thimble panel 16 and two square irons are fixed on one side of the bottom plate 17, and the side of the thimble panel 16 away from the bottom plate 17 is provided with a push rod 161, and one end of the push rod 161 is inserted in the inner mold 2 and It can move axially along the ejector rod 161, the rear template 15 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com