Drive for sheet-fed rotary printing presses

A technology of drive and printing mechanism, applied in the direction of rotary printing machine, printing machine, general parts of printing machinery, etc., can solve the problem that the driving motor coupling has not been further described

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

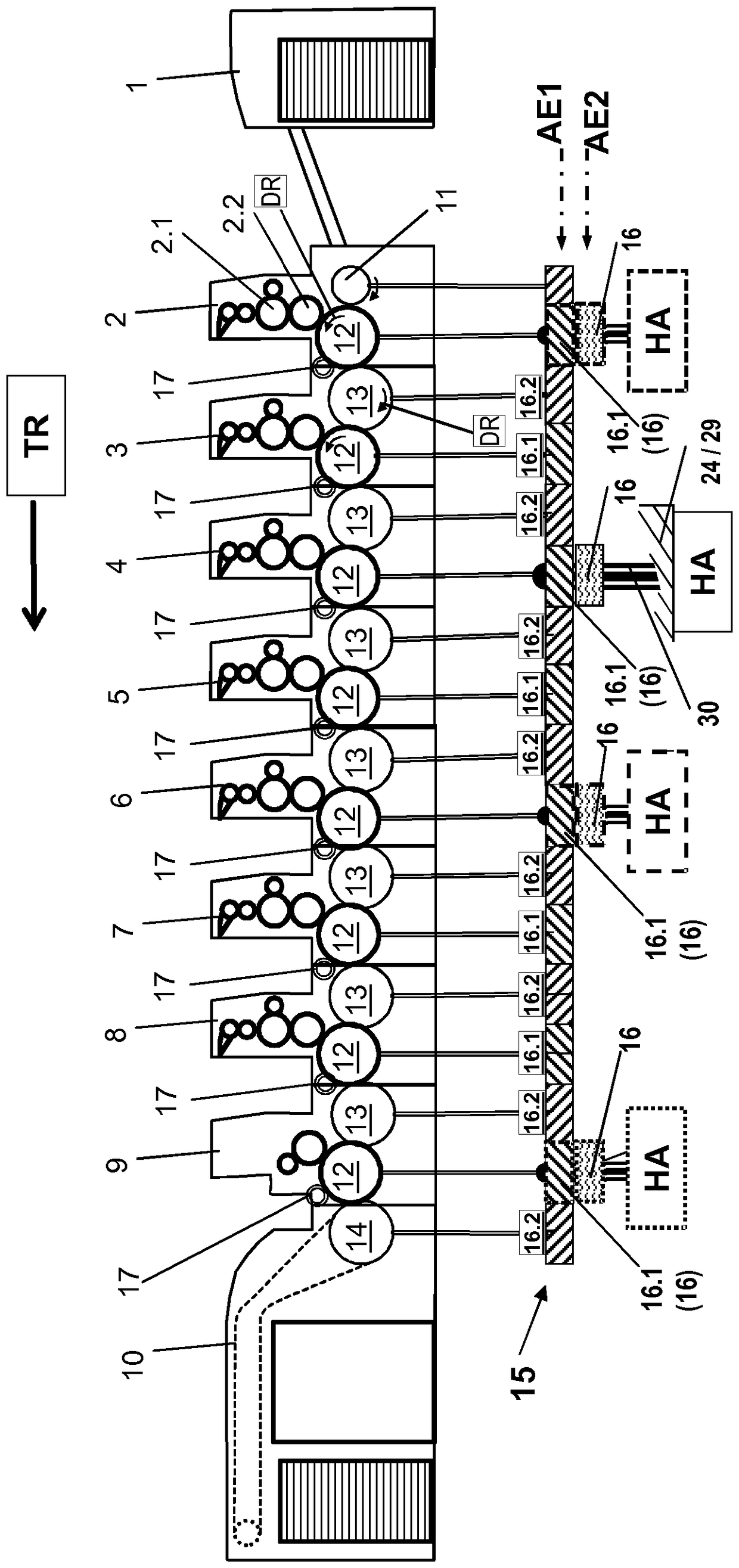

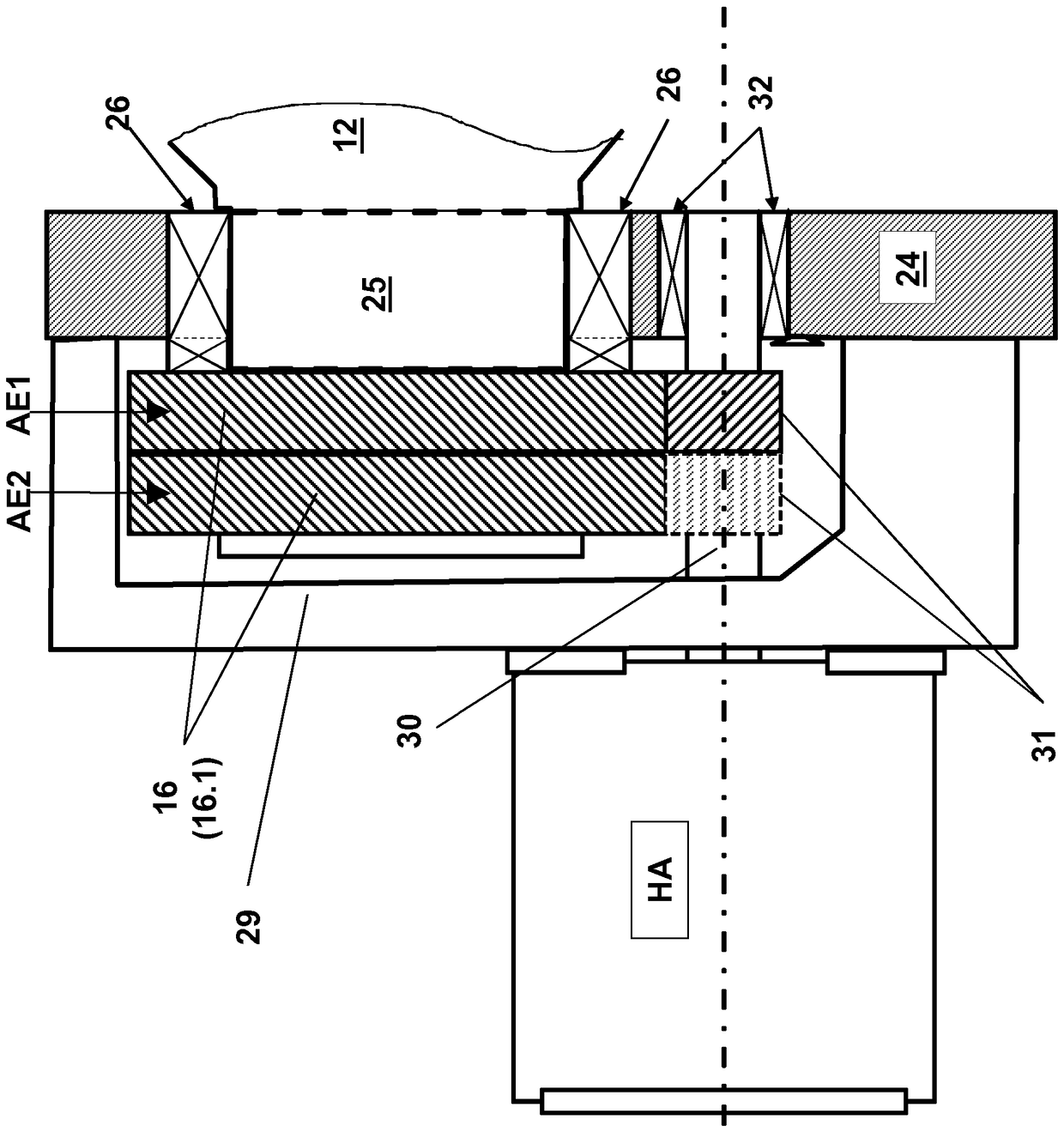

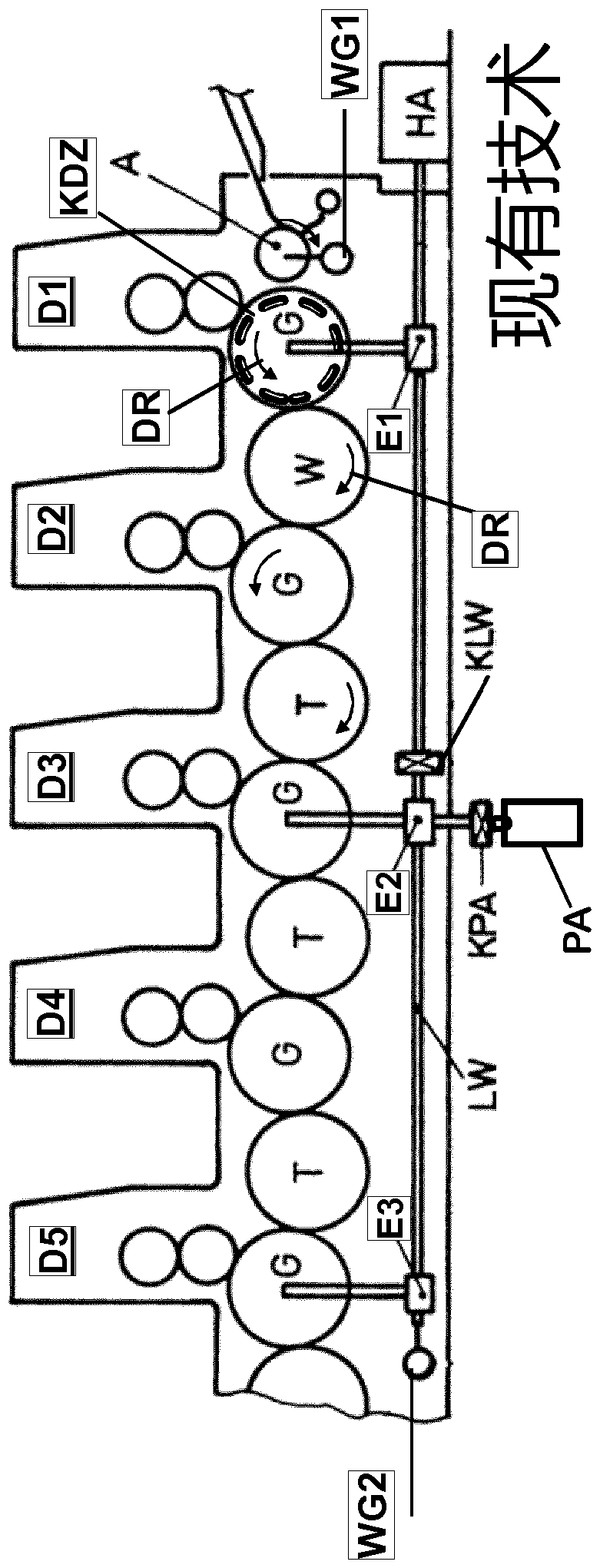

[0059] exist figure 1 The paper offset printing machine on which the invention is based is shown in , the drive arrangement of which is in figure 2 , where five printing units D1 to D5 of an offset paper printing press are shown in side or top view with an impression cylinder G and a transfer or wraparound guide cylinder in between ( Umführtrommeln) T. The printing paper to be printed is fed via the feed reel A to the impression cylinder G of the first printing unit D1. This is followed by the deflection drum W which is upstream of the impression cylinder G of the second printing unit D2. During the changeover from front-side printing to front-side and reverse-side printing, the printing sheet is deflected after the printing unit D1 and fed via the deflection drum W to the impression cylinder G in the printing unit D2 .

[0060] The main drive motor HA is driven into the longitudinal axis LW, which is driven into the drive wheels of the impression cylinders G of the printi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com