Automatic sorting device for bolts and nuts

An automatic sorting and sub-packaging technology, applied in sorting and other directions, can solve problems such as wasting labor, low sorting efficiency, and inconvenient sorting, and achieve the effect of saving labor and improving sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

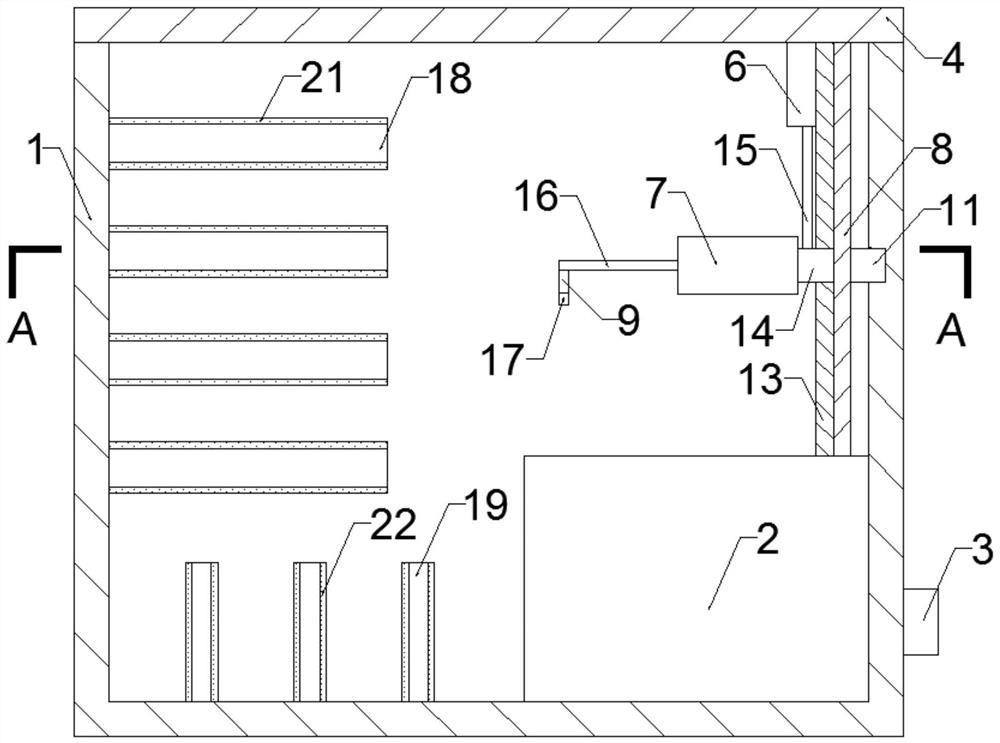

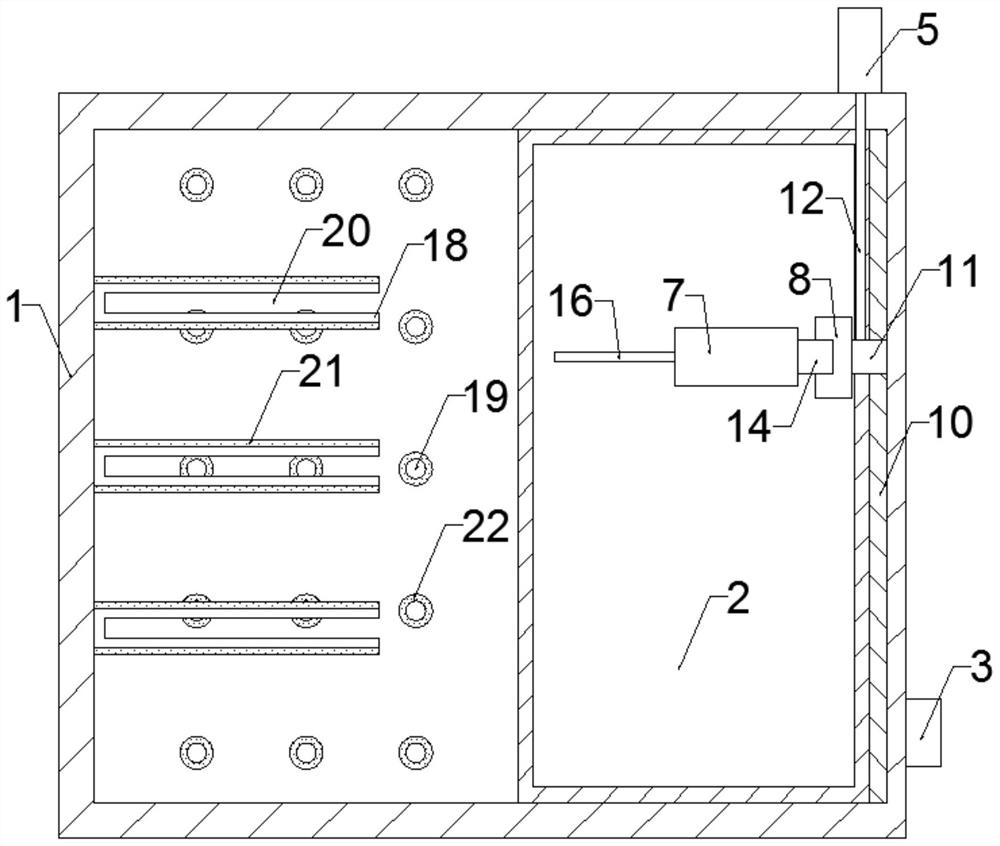

[0019] Such as figure 1 , figure 2 As shown, the automatic sorting device for bolts and nuts includes a packing chamber 1, a storage box 2, a sorting member, a bolt supporting member, a nut supporting member, and a controller 3. The top of the packing chamber 1 is open, and the opening is A baffle 4 is hinged, and the storage box 2 is fixedly connected to one side of the bottom of the packing chamber 1. The sorting member is vertically arranged on the inner wall of the packing chamber 1, the bolt supporting member is arranged on the side wall of the packing chamber 1 and faces the material storage box 2, and the nut supporting member is fixedly connected to the bottom of the packing chamber 1, and the The controller 3 is fixedly connected to the outside of the dispensing chamber 1 . The controller 3 controls the sorting component to place the bolts and nuts in the storage box 2 on the bolt support component and the nut support component respectively, so as to realize automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com