Inclined automatic lifting device

An automatic lifting and tilting technology, applied in the direction of lifting devices, lifting frames, etc., can solve the problems of inability to move, high risk, high degree of danger, etc., and achieve the effect of simple structure, high safety and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

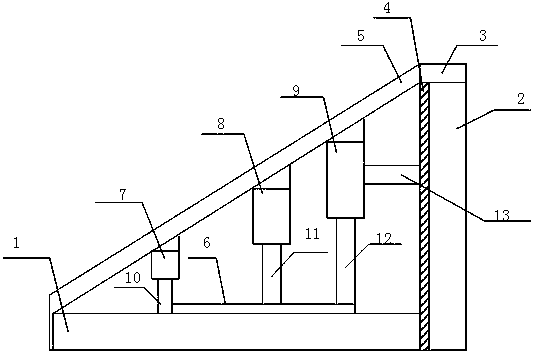

[0011] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0012] Such as figure 1 As shown, a tilting automatic lifting device includes a base 1, a bracket 2, a discharge port 3, a socket 4, an external panel 5, a connecting shaft 6, a first support rod 7, a second support rod 8, a third Support rod 9, the first hydraulic rod 10, the second hydraulic rod 11, the third hydraulic rod 12 and the cross bar 13, the support 2 is installed on the right side of the base 1, the discharge port 3 is installed on the top of the support 2, and the socket 4 is installed on the On the left side of the bracket 2, the outer panel 5 connects the base 1 and the discharge port 3, the first support rod 7, the second support rod 8 and the third support rod 9 are installed between the base 1 and the outer panel 5 in sequence, and the first hydraulic rod 10. The seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com