Scaffold with adjustable height

A technology of height adjustment and scaffolding, which is applied in the field of scaffolding, can solve problems such as the inability to quickly and conveniently adjust the height of the scaffolding, the inability to ensure the scaffolding, and the inability to further ensure the stability of the scaffolding, so as to reduce the possibility of overturning, reduce the occupied space, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

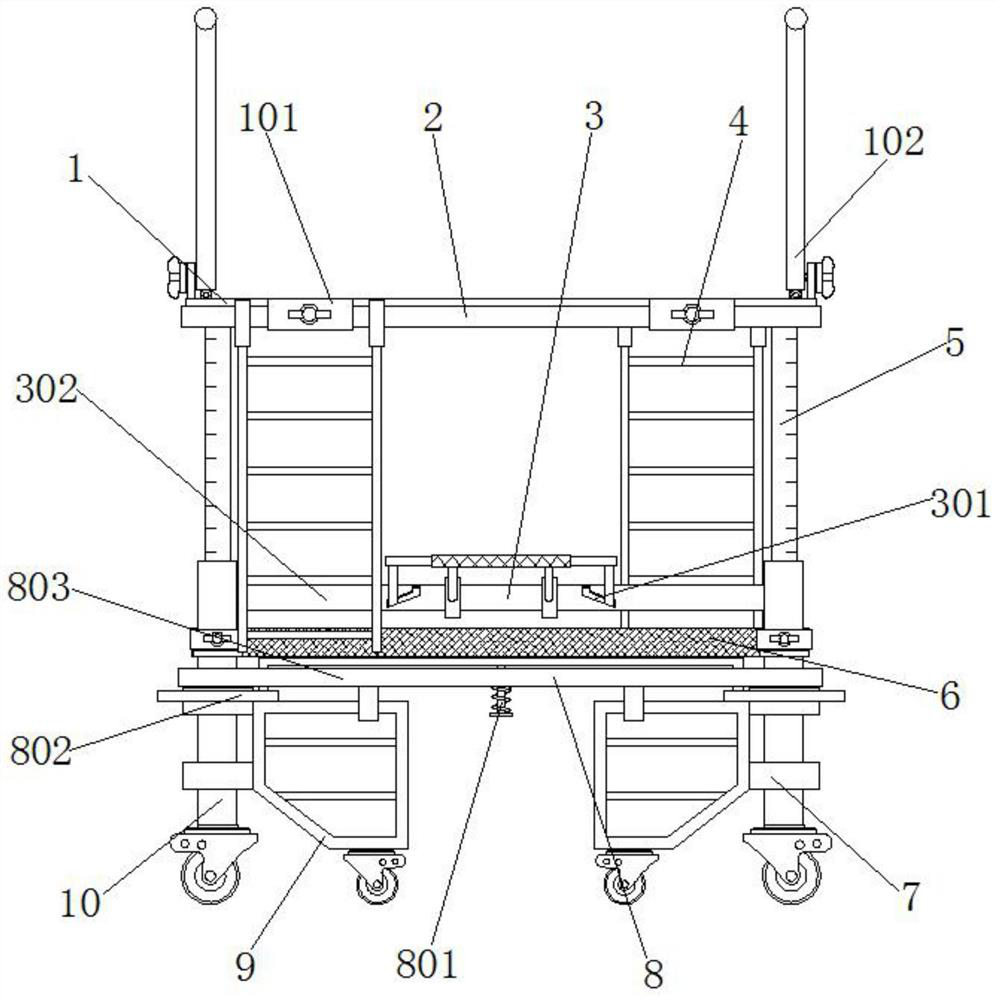

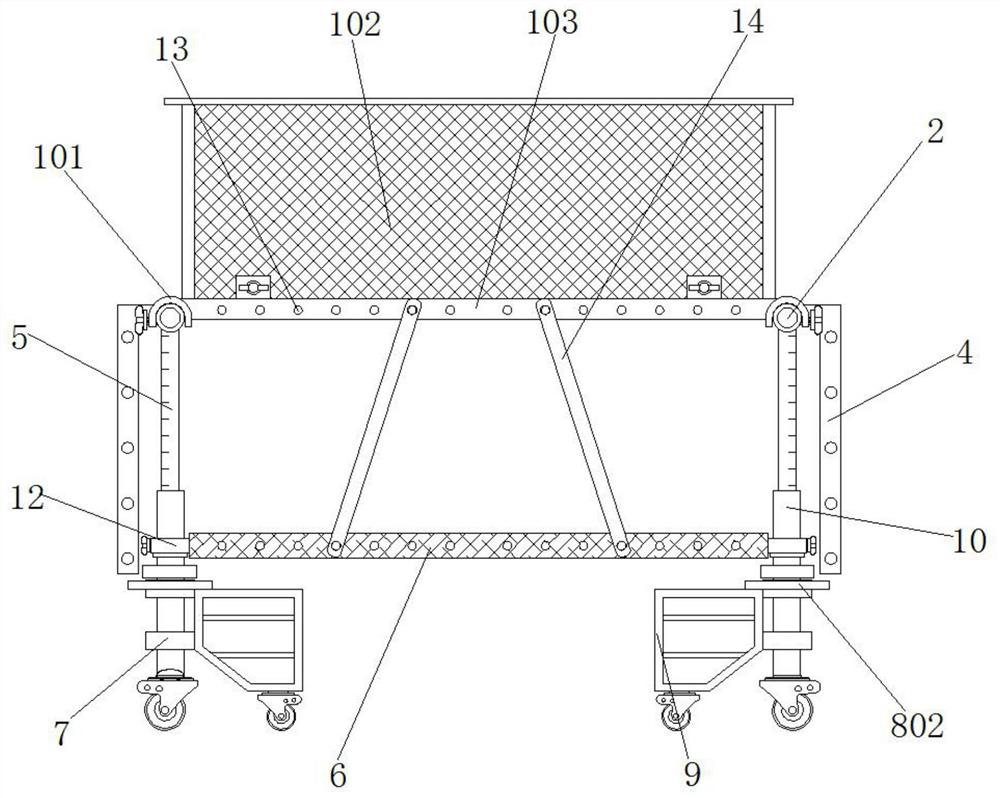

[0046] Example 1, such as Figure 1-9 As shown, when installing the scaffolding, the installer first erects the four sets of installation pipes 10, allows the installation pipes 10 and the universal wheels at the bottom of the support frame 9 to be placed on the ground, and then lifts the connecting plate 6 into the four sets of installation pipes 10 between, and through four sets of second steel pipe buckles 12, the connecting plate 6 is fixedly connected with the four sets of installation pipes 10, and then the auxiliary plate 807 is lifted up manually, so that the two ends of the bottom of the latch 304 leave the corresponding fixing hole 805, Unfix the position of the support frame 9, and rotate the support frame 9 to the outside of the scaffold as attached to the instruction manual. Figure 4 , and then loosen the auxiliary plate 807, so that the bottoms of the two ends of the U-shaped bar 804 snap into the corresponding fixing holes 805, so that the support frame 9 is li...

Embodiment 2

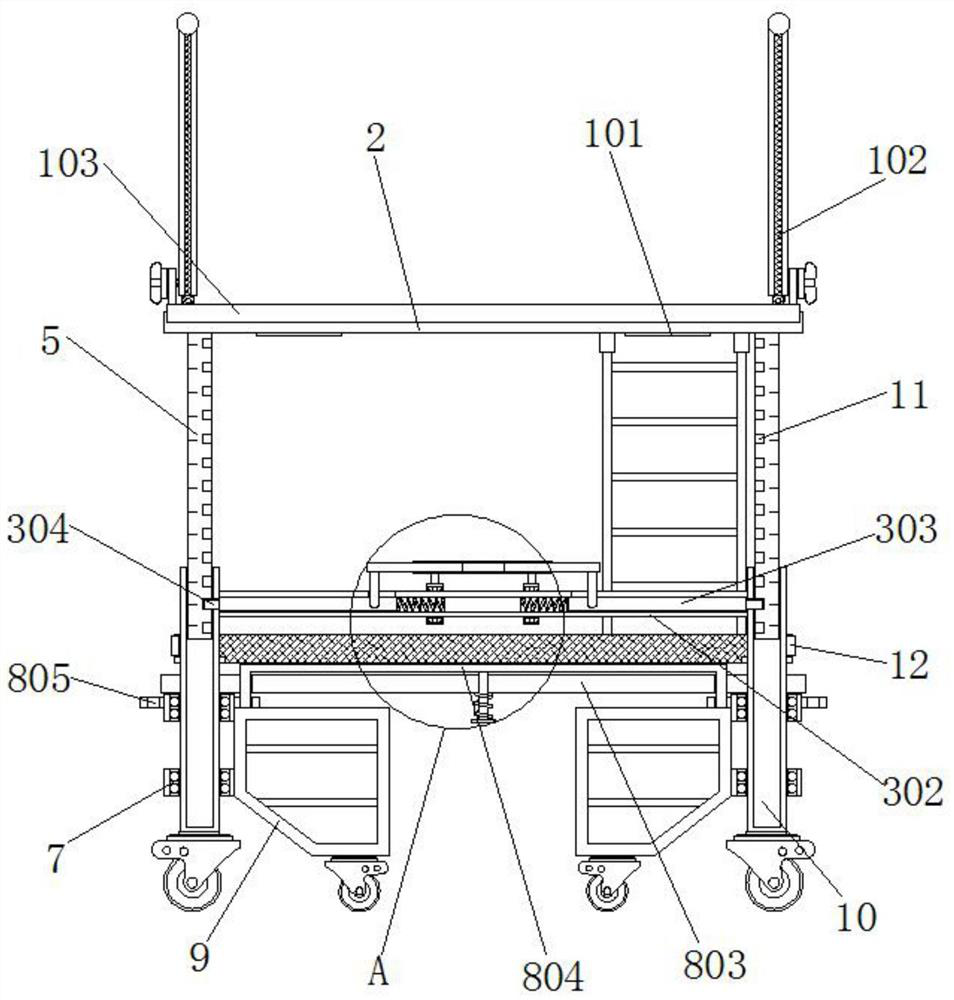

[0047] Example 2, such as Figure 1-9 As shown, when it is necessary to adjust the height of the entire scaffold, the four sets of connecting rods 14 are first removed from the corresponding limit protrusions 13, and then the operator supports the platform board 103 with both hands, and the two sets of hand pipes 308 are moved to the The inner side of the scaffold rotates, forcing the movable rod 303 to gradually move towards the middle position of the connecting pipe 302. After the latch 304 leaves the inside of the pin hole 11, the limiting hole 301 limits the L-shaped inserting rod 307, and at the same time the L-shaped inserting The rod 307 also extends into the inside of the handle pipe 308, the return spring 306 shortens and stores elastic potential energy, and then the installer can lift the construction frame assembly 1 upwards, and the four sets of lifting rods 5 also follow the direction of the installation pipe 10. The inside protrudes, and after the construction fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com