Oil level state detection method and device of transformer

A state detection and transformer technology, applied in measuring devices, lubrication indicating devices, instruments, etc., can solve problems such as hidden safety hazards, inability to grasp oil level status in real time, transformers unable to operate safely, etc., to ensure safe and stable operation and accurate monitoring results. Reliable, free of human resource consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

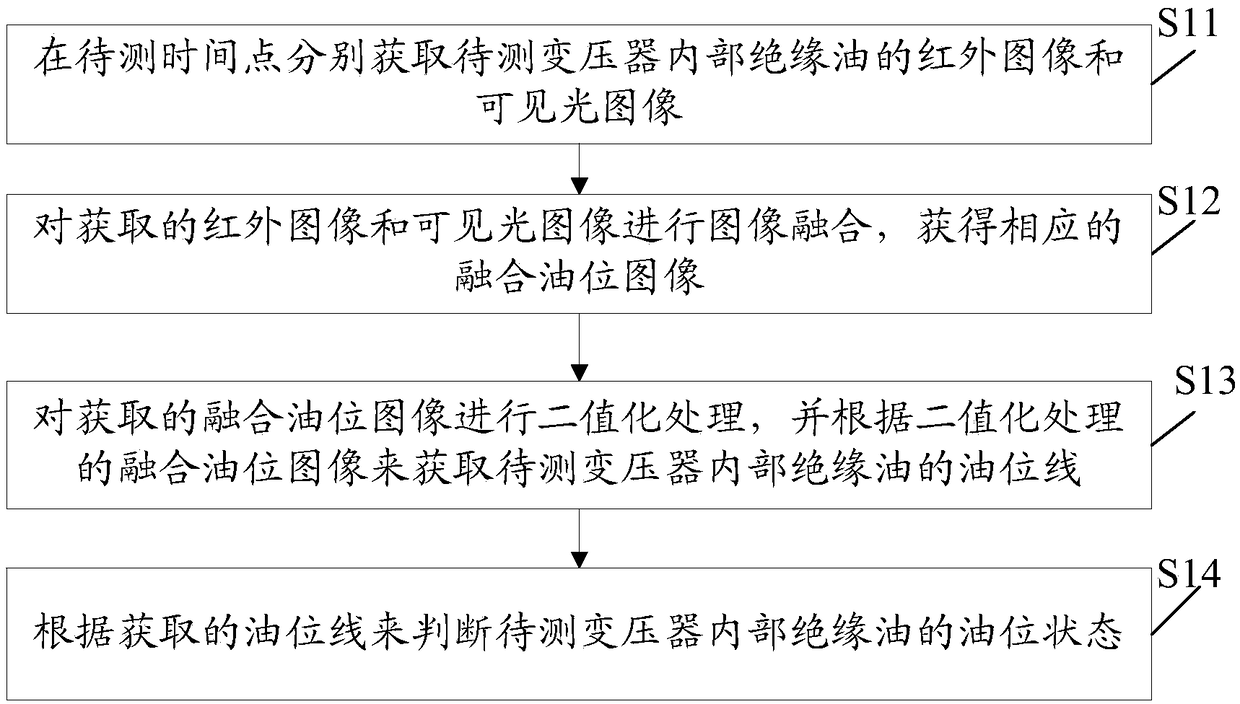

[0045] An embodiment of the present invention provides a method for detecting the oil level state of a transformer, which is suitable for monitoring the oil level state of the insulating oil in the transformer, see figure 1 , the method can include:

[0046] In step S11, the infrared image and the visible light image of the insulating oil inside the transformer to be tested are acquired respectively at the time point to be tested.

[0047] In this embodiment, the infrared image and the visible light image of the insulating oil inside the transformer to be tested can be respectively obtained through the peep window of the oil level indicator of the transformer to be tested. Of course, it should be noted that the infrared image and the visible light image are at the same position, The images were taken at the same angle and at short time intervals for subsequent image fusion.

[0048] Step S12, performing image fusion on the acquired infrared image and visible light image to ob...

Embodiment 2

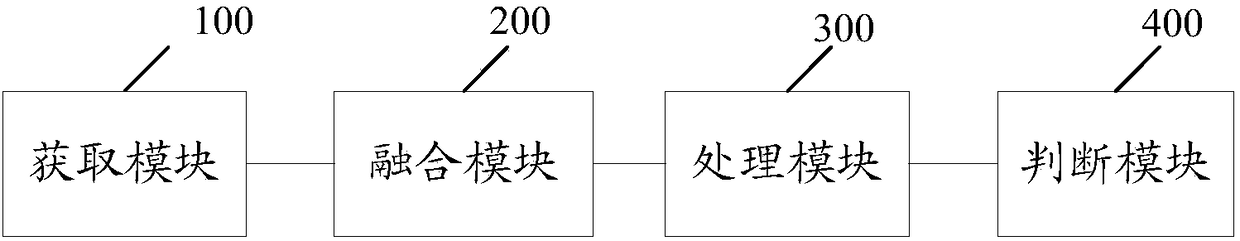

[0075] An embodiment of the present invention provides a transformer oil level detection device, which implements the method described in Embodiment 1, see image 3 , the device may include: an acquisition module 100 , a fusion module 200 , a processing module 300 , and a judging module 400 .

[0076] The acquisition module 100 is configured to respectively acquire an infrared image and a visible light image of the insulating oil inside the transformer to be tested at the time point to be tested.

[0077] In this embodiment, the infrared image and the visible light image of the insulating oil inside the transformer to be tested can be respectively obtained through the peep window of the oil level indicator of the transformer to be tested. Of course, it should be noted that the infrared image and the visible light image are at the same position, The images were taken at the same angle and at short intervals for subsequent image fusion.

[0078] The fusion module 200 is configu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com