Pressure method for driving pressure cavity

A technology of driving pressure and pressure, which is applied in the direction of boiling water utensils, cooking utensils, beverage preparation devices, etc., and can solve problems such as odor, brewing milk powder, and inability to use each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below with reference to the drawings and embodiments.

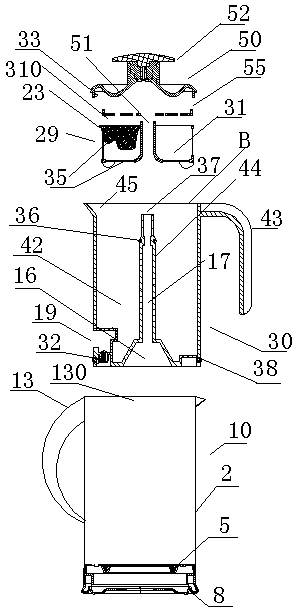

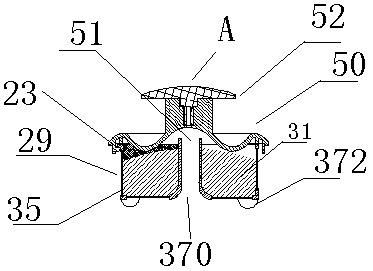

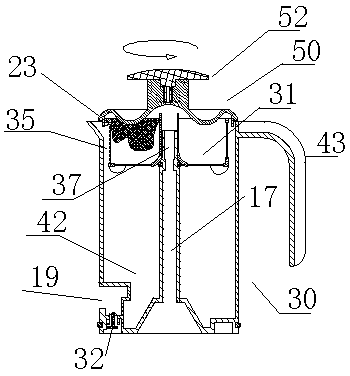

[0077] See Figure 1-Figure 10 , Drive the pressure chamber and the kettle, the main body includes the brewing collection piston container 30, the hot water container 10, the sealed pressure chamber 15, and the filter 29, characterized by:

[0078] The brewing collection piston container 30 is provided with a liquid inner cavity 42 for collecting the liquid filtered by the filter 29;

[0079] A first sealing position 38 is provided between the periphery of the brewing collection piston container 30 and the inner wall of the hot water container 10 to seal sleeves and slide up and down to form a sealed pressure chamber 15; the downstream of the sealed pressure chamber 15 penetrates the piston connected to the filter 29 for brewing Cavity 31;

[0080] The filter 29 is used to contain and dissolve the material to be brewed; the upstream of the filter 29 is provided with a water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com