Installation method of a rudder-propeller integrated propulsion system

A technology of propulsion system and installation method, which is applied in the directions of transportation and packaging, ship construction, ship design, etc., can solve the waste of manpower and dock cycle, it is difficult to meet the high-precision technical requirements of the rudder propeller, and it is difficult to consider the welding shrinkage of the rudder barrel. and other problems, to achieve the effect of shortening the dock cycle, saving labor costs, and eliminating the boring process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

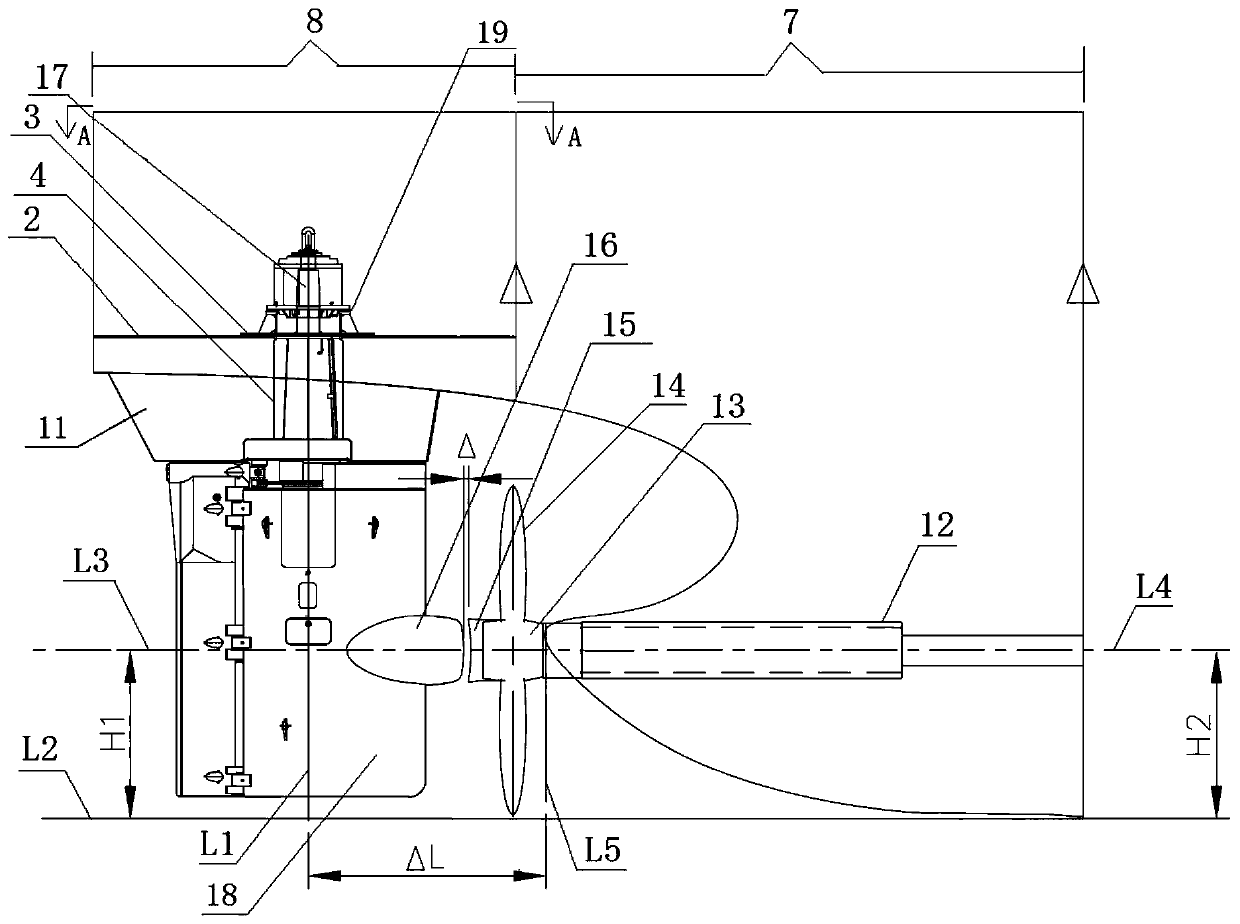

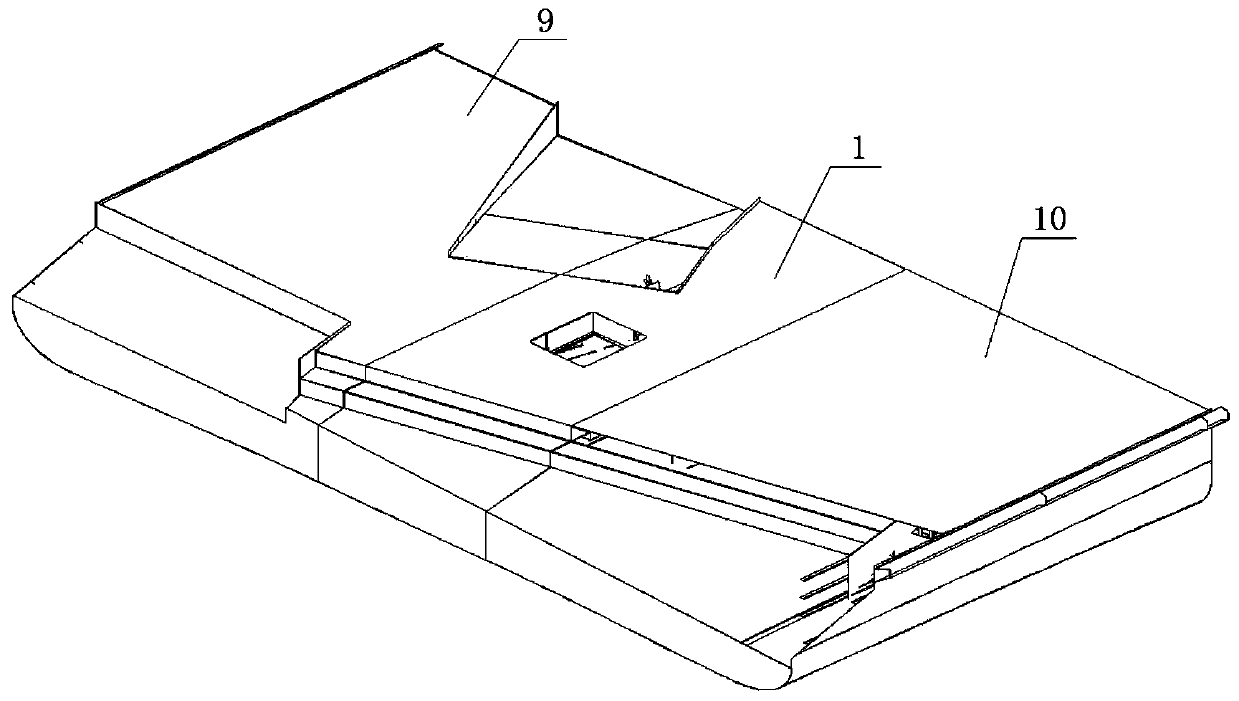

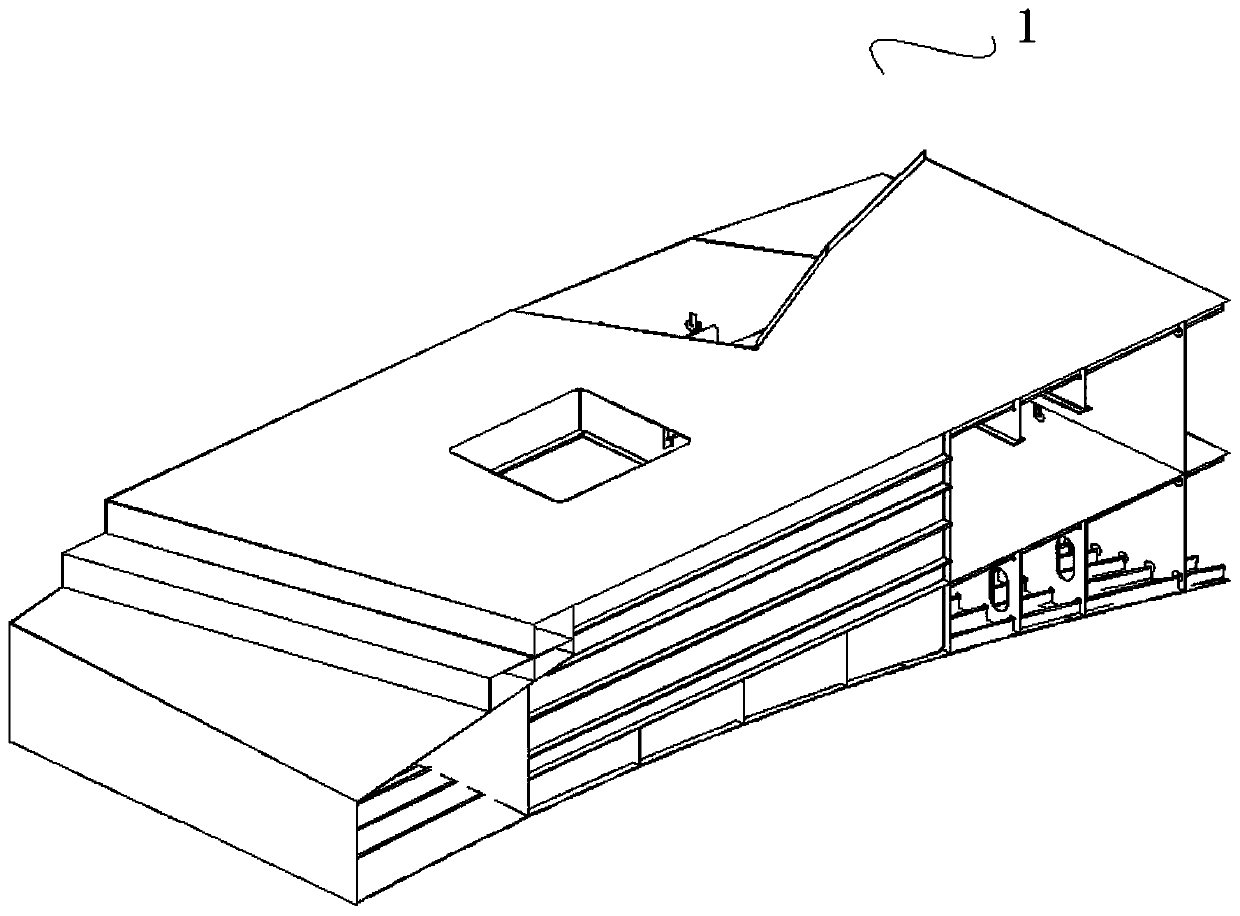

[0041] like Figure 1-10 As shown, the installation method of the rudder-propeller integrated propulsion system in this embodiment includes the following steps, S1, pre-installation of the rudder cylinder in sections, S2, prediction of the deformation of the stern general assembly, S3, and the stern general assembly , S4, shafting, propeller and rudder blade installation;

[0042] The segmental pre-installation of the S1 rudder stock includes the following steps:

[0043] ① Level the section 1 where the rudder stock tube is located, adjust the level of the steering gear platform 2 and the base plate 3 in turn,

[0044] ②Find out the center line L1 of the theoretical rudder system on the section 1 where the rudder stock barrel is located, and project the center line L1 of the theoretical rudder system onto the horizontal baseline L2,

[0045] ③ After hoisting the rudder stock tube 4 in place, use a total station to measure the level of the steering gear platform,

[0046] ④ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com