Limiting rod

A technology of limit rods and connecting bolts, applied in the field of limit rods, can solve problems such as troublesome processing and unguaranteed processing accuracy, and achieve the effects of easy processing, no welding process, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

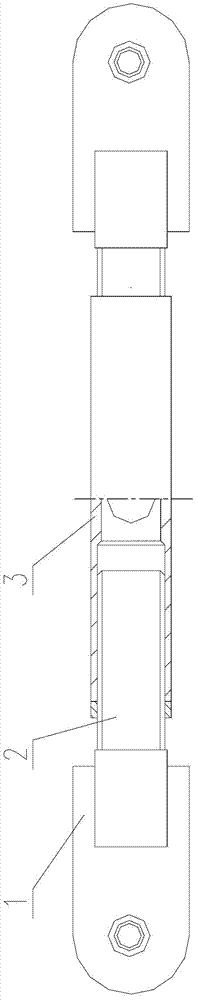

[0010] Such as figure 1 As shown, the commonly used limit rods now include a connecting plate 1, a connecting bolt 2 and a connecting pipe 3. After the connecting plate 1 and the connecting bolt 2 are processed and formed, they are fixed by welding or other connection methods. The two ends of the connecting pipe 3 are first Carry out boring, then tap and connect with connecting bolts.

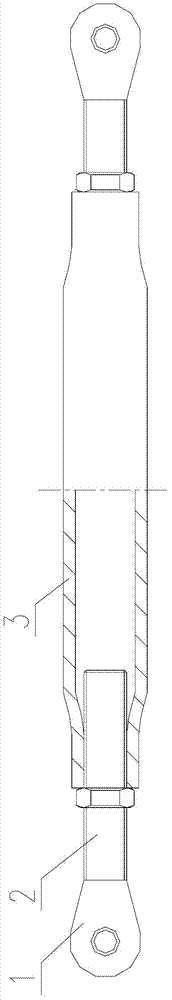

[0011] figure 2 The limit rod of the present invention includes a connecting plate 1, a connecting bolt 2 and a connecting pipe 3, and the connecting plate 1 and the connecting bolt 2 are an integral structure. The structure is simple, the parts are few, and the processing technology only involves turning and drilling without welding. The connecting plate 1 and the connecting bolt 2 are integrally forged, which enhances the overall rigidity of the limit rod. The connecting pipe 3 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com