Shifting fork control method during DCT (Dual Clutch Transmission) speed changer downshift process

A control method and transmission technology, which are applied in the directions of transmission control, elements with teeth, climate sustainability, etc., can solve the problems of poor quality of shifting and failure of shifting, so as to improve the quality of shifting and overcome the problems of shifting. Effects of excessive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

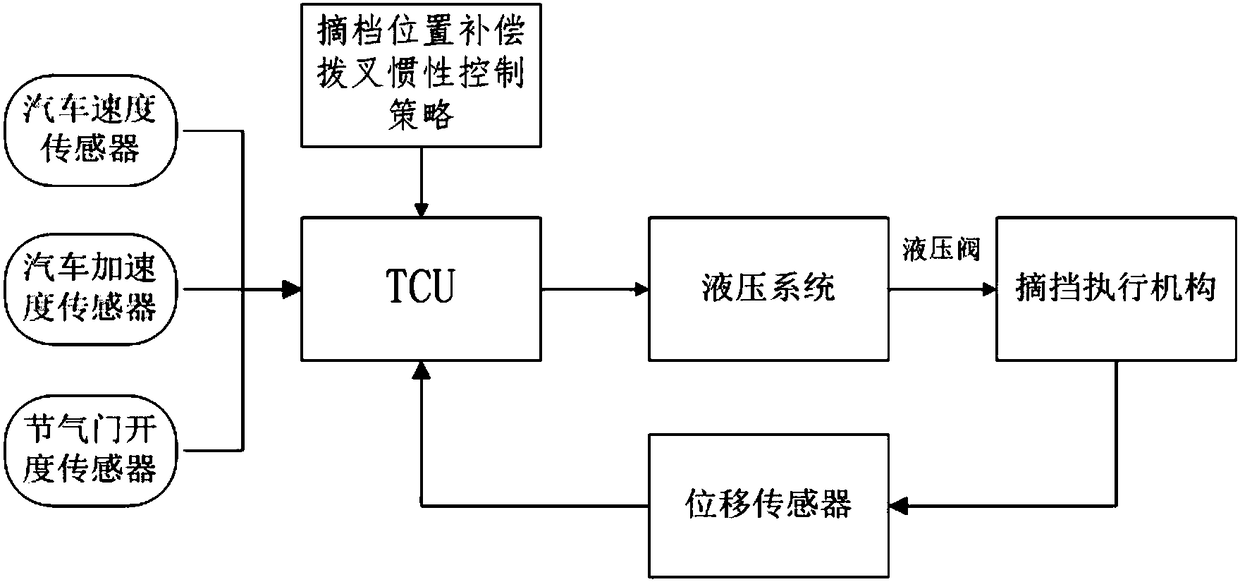

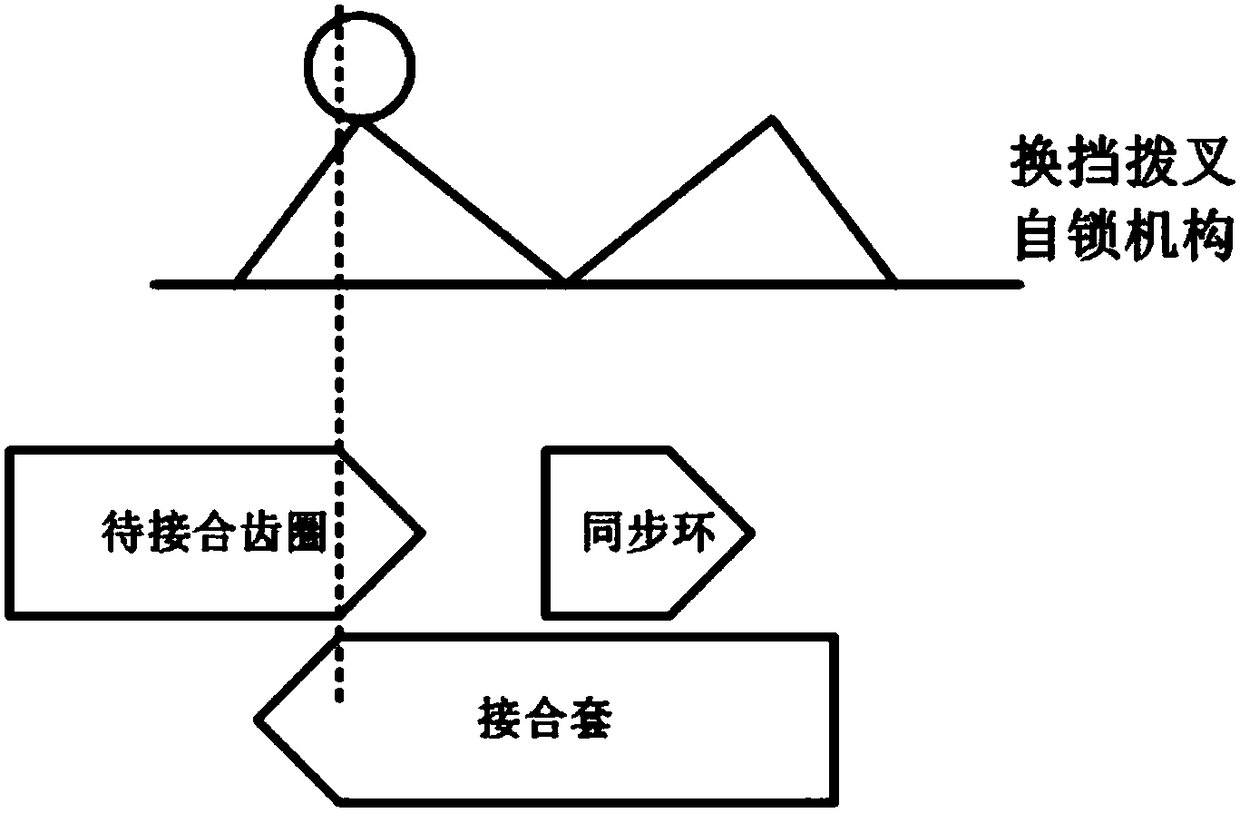

[0033] Such as figure 1 As shown, the present invention provides a method for controlling a shift fork in the gear removal process of a DCT transmission. After the TCU receives the signals from the accelerator opening, vehicle acceleration and vehicle speed, it sends a command signal to the hydraulic system through comprehensive analysis. The shift fork and the combination sleeve move, and at the same time, the position sensor on the shift fork feeds back the displacement signal of the shift fork to the TCU at all times. The TCU stores the gear-off position compensation inertia control strategy of the shift fork. After the gear-off position compensation inertia control strategy in the TCU is processed, the best unloading oil pressure position is obtained. The TCU sends a com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com