A scale-adjustable two-way synchronous compression experiment in-situ observation device

A two-way synchronization and observation device technology, which is applied to measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve problems such as errors, less equipment, and incomplete theoretical results, so as to ensure accuracy and rationality. The effect of reducing experiment cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

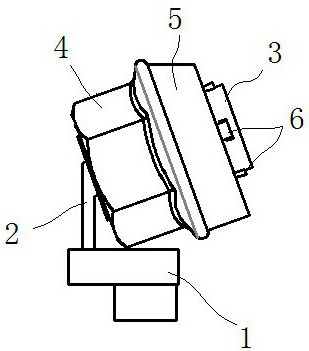

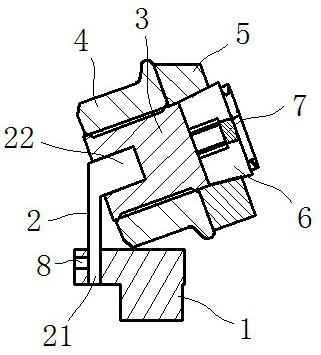

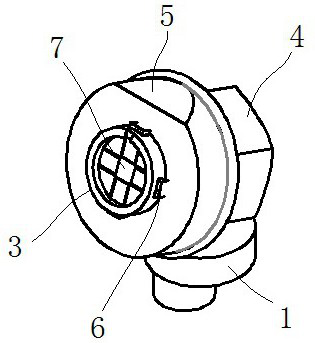

[0019] see Figure 1 to Figure 4 , the scale-adjustable two-way synchronous compression experiment in situ observation device includes a base 1 , a support column 2 , a screw 2 , a loading nut 4 , a pressure ring 5 and a wedge 6 . The screw 3 is fixed above the base 1 through the support column 2, and it is composed of a lower threaded part 31 and an upper loading part 32. The threaded part 31 is threadedly matched with the loading nut 4, and the top of the loading part 32 is provided with a The groove 321 of the sample is evenly provided with accommodating groove 322 corresponding to the wedge block 6 along the circumferential direction on the side wall of the loading part 32, and the upper part of the groove bottom of the accommodating groove 322 penetrates through the lower part of the side wall of the groove 321 , the shape of the wedge-shaped block 6 is large a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com