Anti-deposition liquid stirring tank

A stirring tank and anti-sedimentation technology, which is applied in the direction of dissolution, mixers, chemical instruments and methods, etc., can solve the problems of high cost, deformation and damage of stirring blades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

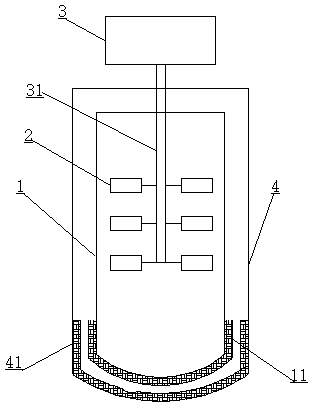

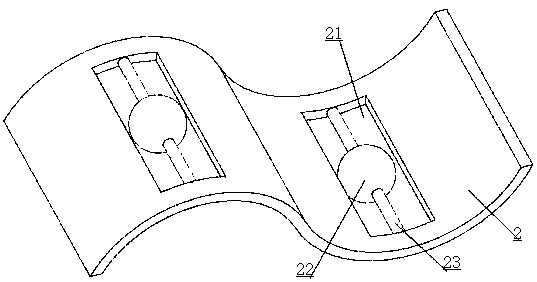

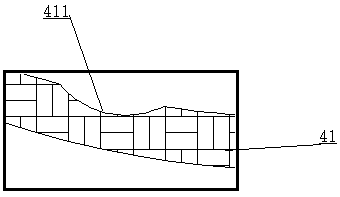

[0014] This embodiment provides an anti-sedimentation liquid stirring tank, such as figure 1 , figure 2 , image 3 , including an inner tank body 1 and a plurality of stirring blades 2 arranged in the inner tank body 1, a driving mechanism 3 for driving the stirring blades, the stirring blades 2 are provided with a through hole 21, and a rotatable Spoiler ball 22; Also includes the outer tank body 4 that is wrapped in the inner tank body 1; The inner wall of the outer tank body is provided with a main magnet layer 41; The auxiliary magnet layer 11 ; the inner tank body 1 is suspended inside the outer tank body 4 through the repulsive force between the auxiliary magnet layer 11 and the main magnet layer 41 .

[0015] Further, it also includes a transmission shaft 31 arranged in the inner tank body 1, one end of the transmission shaft 31 is connected to the drive mechanism 3, and the stirring blade 2 is radially arranged at the other end of the transmission shaft 31; the The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com