Integral three-dimensional (3D) molded crescent piece underwear structure

A crescent-shaped, forming technology, applied in clothing, bras, applications, etc., can solve the problems of lack of, lack of support and side thrust gathering effect, unable to form the interaction between the support and side thrust, etc., so as to reduce the force. Feel, enhance the scientific, enhance the effect of beauty appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment the present invention is further described in detail.

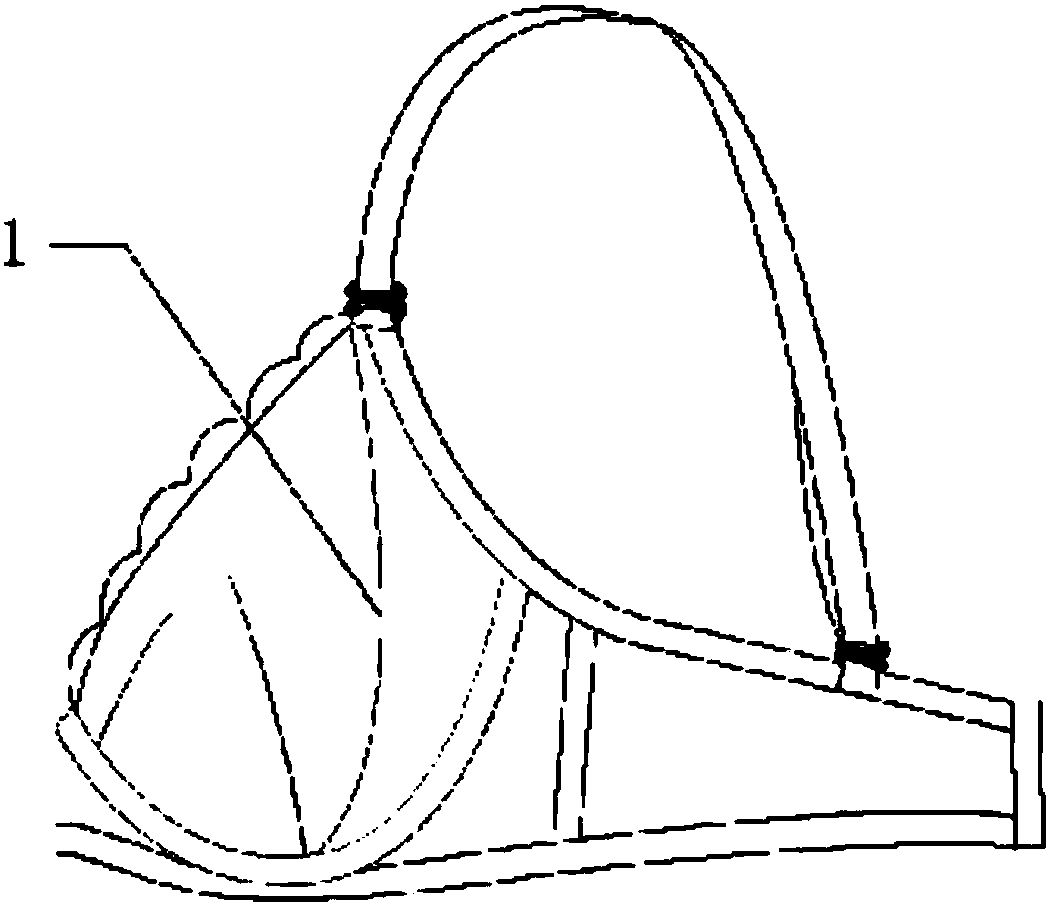

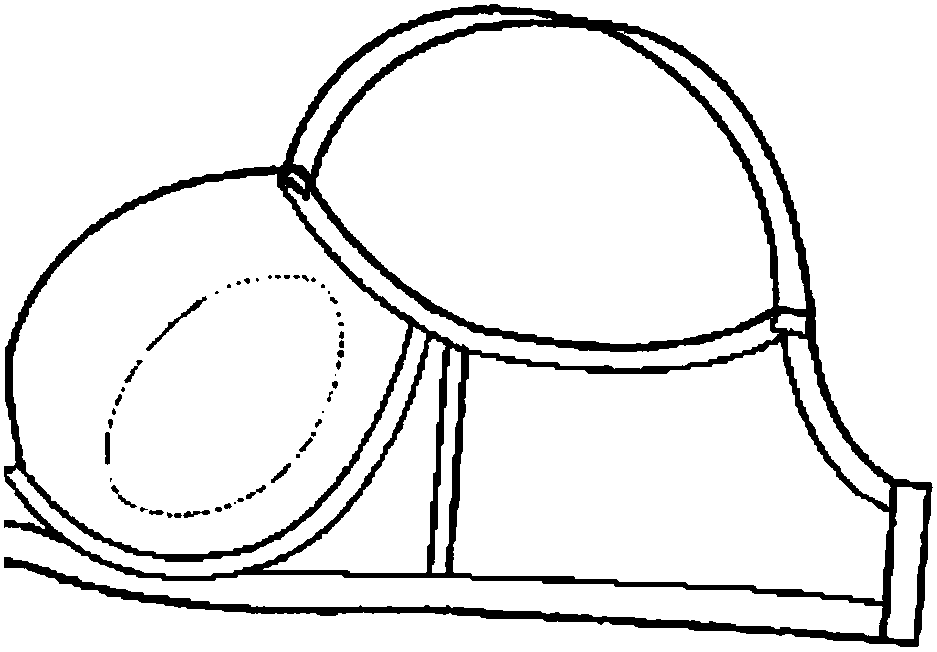

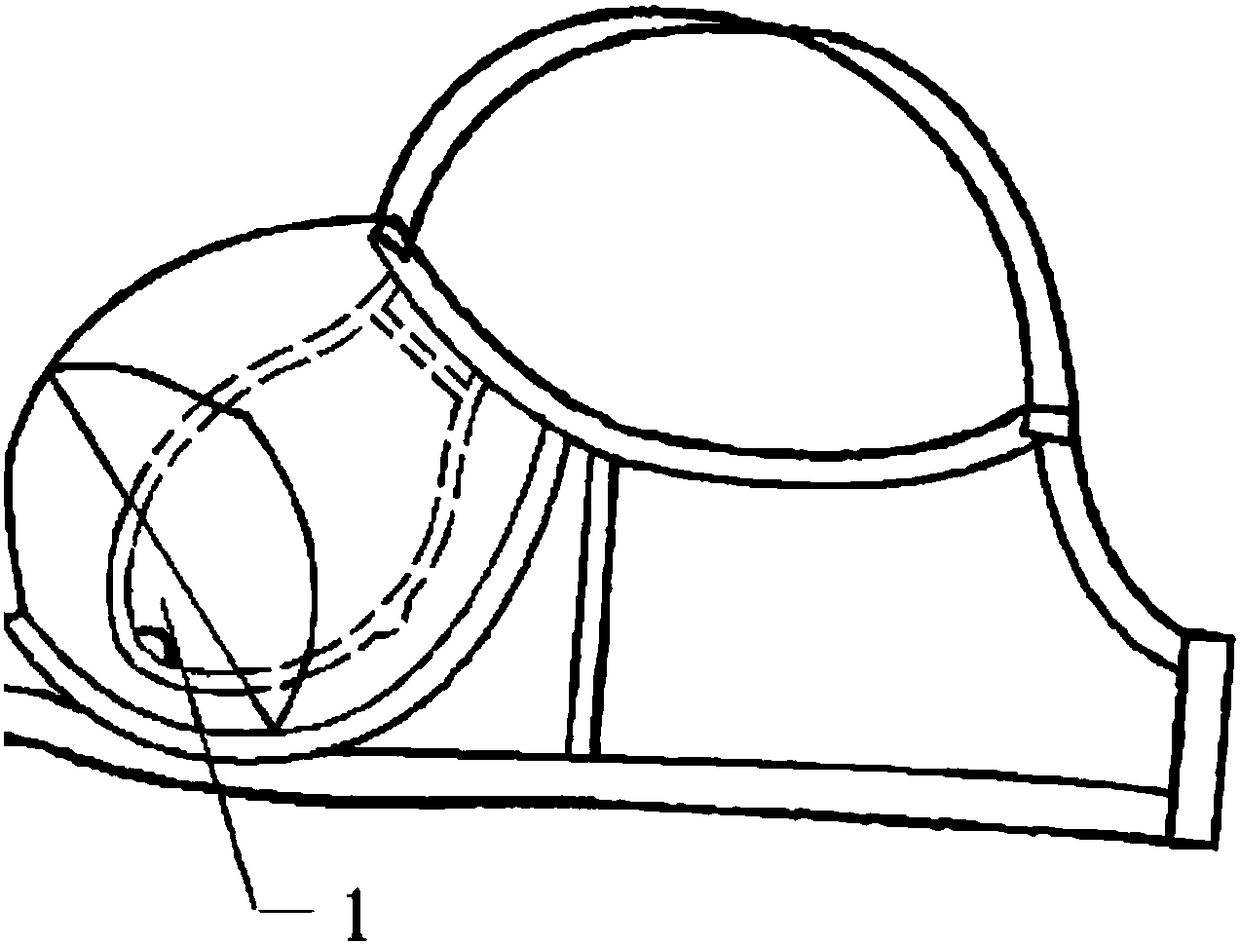

[0026] Such as Figure 4 to Figure 6 As shown, an underwear structure of an integrated 3D forming crescent piece, including a cup 1, a crescent piece structure 2 is sewn inside the cup 1, and the lower edge of the crescent piece structure 2 is fixed to the bottom edge of the cup 1 , the rear edge of the crescent structure 2 is sewn to the side of the cup 1, and the upper edge of the crescent structure 2 is fixed to the upper edge of the cup 1;

[0027] The crescent piece structure 2 includes two layers of cotton core layers 2-1, the two layers of cotton core layers 2-1 are bonded, and the outer sides of the two layers of cotton core layers 2-1 are evenly bonded to the breathable fabric layer 2-1. 2. The lower part of the crescent sheet structure 2 is molded with a cushion part 2-3 protruding inwardly, and the upper part of the crescent sheet structure 2 is molded with a three-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com