Pilot type pipe burst shutoff valve and method for controlling same

A pilot-operated, shut-off valve technology, applied in the field of shut-off valves, can solve the problems of low serialization, low adjustment precision, high manufacturing cost, and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

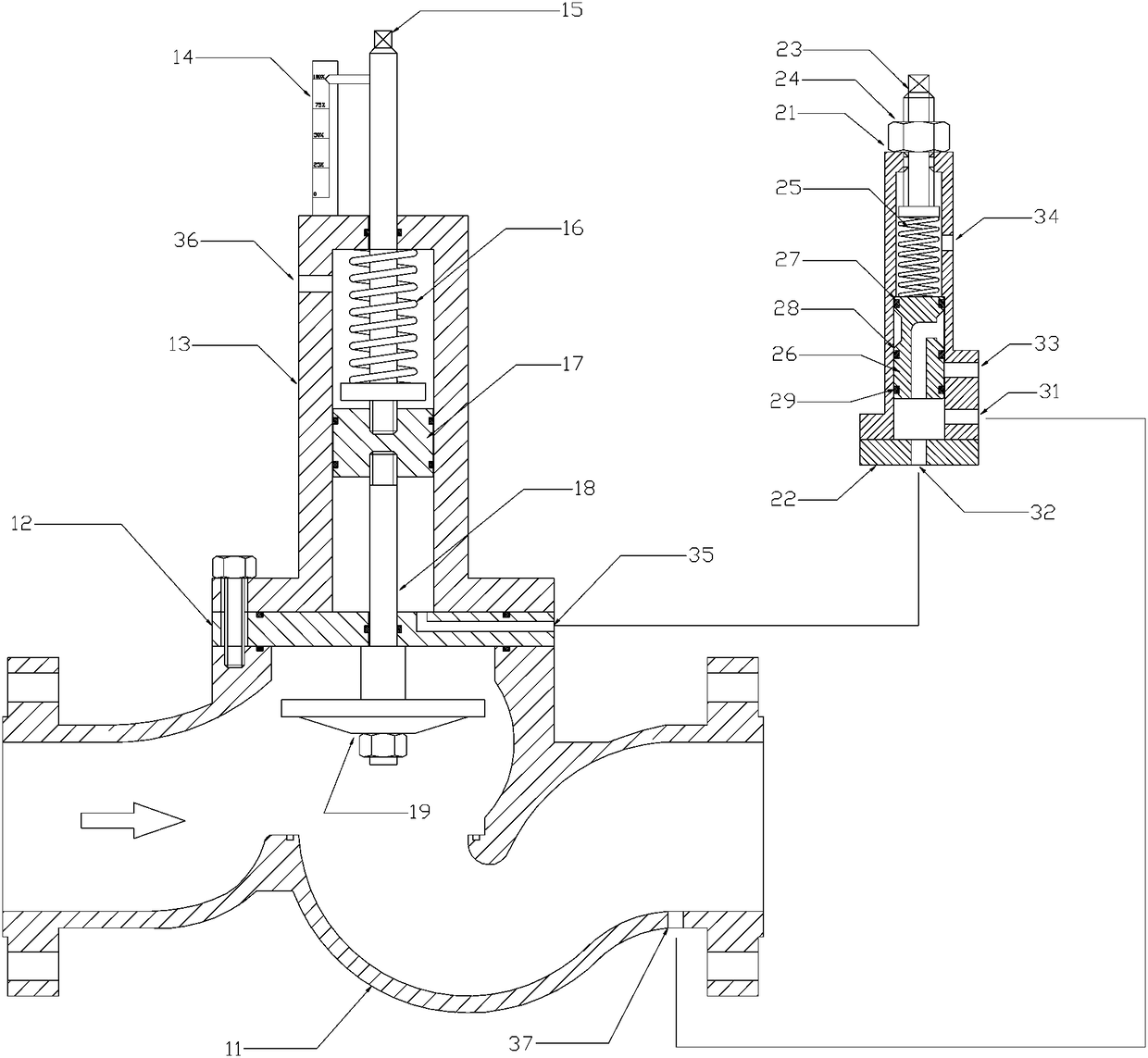

[0041] like figure 1 As shown, the pilot-operated squib shut-off valve includes a main valve, and the main valve is connected to the pilot valve through a connecting pipeline; the pilot valve includes a pilot valve body 21, and the bottom of the pilot valve body 21 is equipped with a pilot valve The end cover 22, the pilot valve body 21 and the pilot valve end cover 22 form a closed chamber, the pilot valve spring 25 and the pilot valve spool 26 are installed inside the closed chamber, and the top of the pilot valve body 21 is installed with An adjustment bolt 23 , the bottom end surface of the adjustment bolt 23 is in contact with the top end of the pilot valve spring 25 ; the preload of the pilot valve spring 25 can be adjusted through the adjustment bolt 23 .

[0042] Further, the bottom side of the pilot valve body 21 is processed with a first pilot valve opening 31, and the first pilot valve opening 31 communicates with the outlet side opening 37 of the main valve; the pi...

Embodiment 2

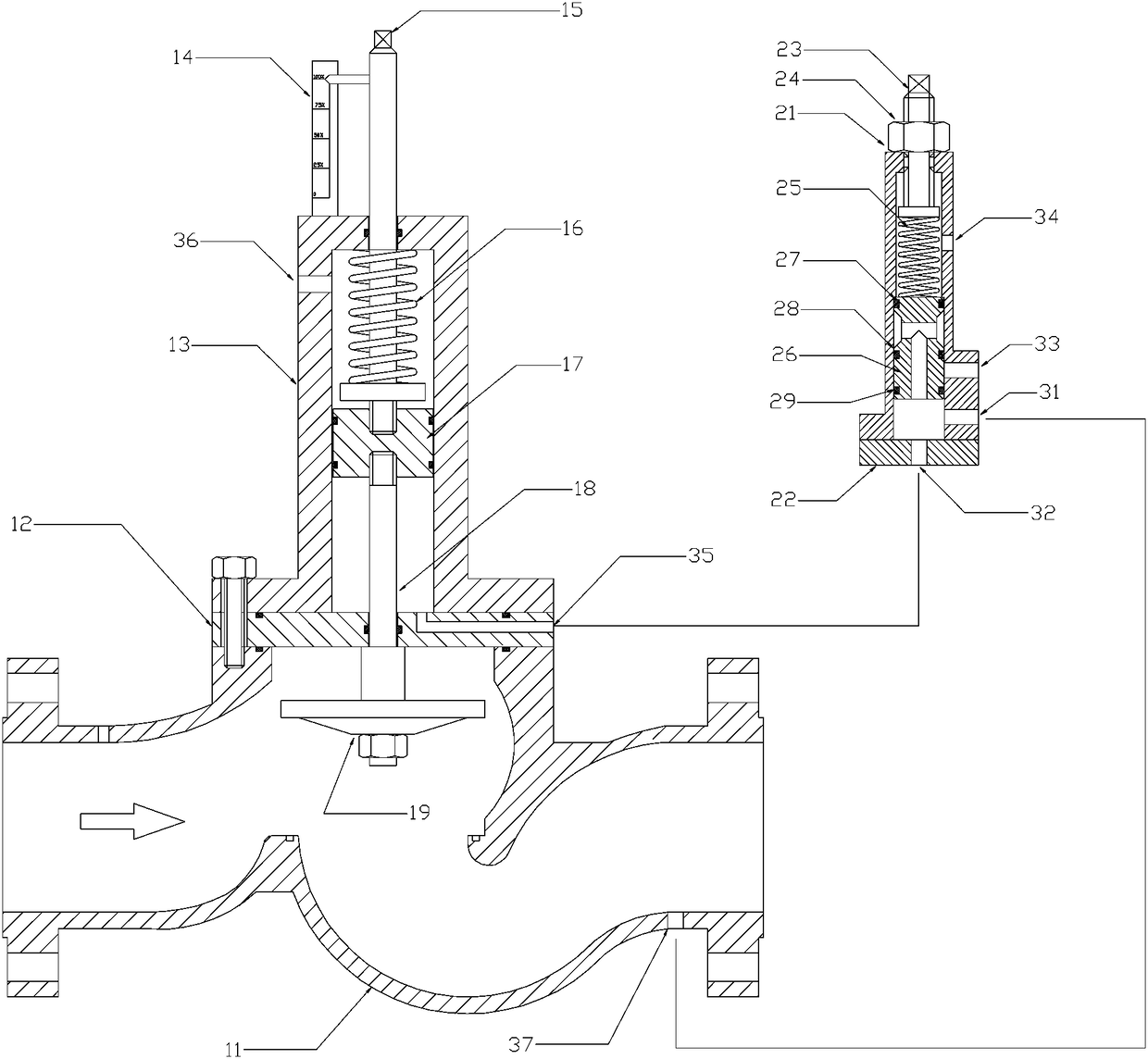

[0051] like figure 2 , in this embodiment, the structure of the main valve is the same as in Embodiment 1, and the center hole structure of the pilot valve in this embodiment is different from that in Embodiment 1. In this embodiment, its center hole is located at the pilot valve The central position of the valve core 26, and the central hole communicates with the annular gap formed by the first sealing ring 27 and the second sealing ring 28 through a transverse through hole communicating with it.

Embodiment 3

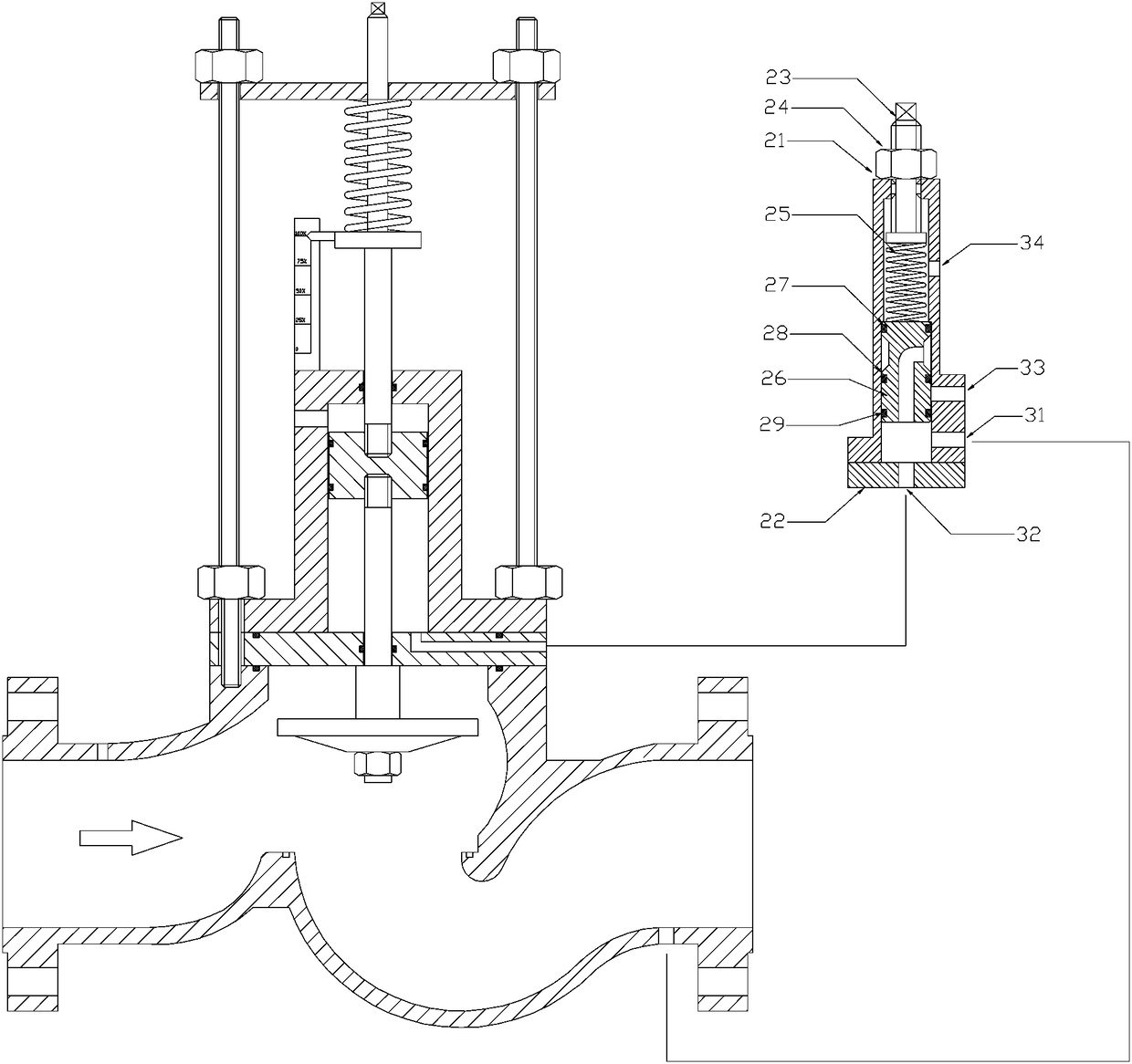

[0053] like image 3 , in this embodiment, the structure of the main valve is the same as in Embodiment 1. In this embodiment, the return spring 16 is installed outside the cylinder body 13, and then exerts elastic force on the moving parts of the main valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com