Automatic welding system for corrugated membrane sheet of membrane type liquefied-gas cargo hold, structure for guiding and fixing automatic welding apparatus for corrugated membrane sheet of membrane type liquefied-gas cargo hold, and structure for guiding automatic welding apparatus for corrugated membrane sheet of membrane type liquefied-gas cargo hold

A technology of automatic welding and corrugated film, which is applied in the direction of bulk goods, fixed-capacity gas storage tanks, welding equipment, etc., can solve the problems of machinability and stability degradation, support automatic welding machinery, difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

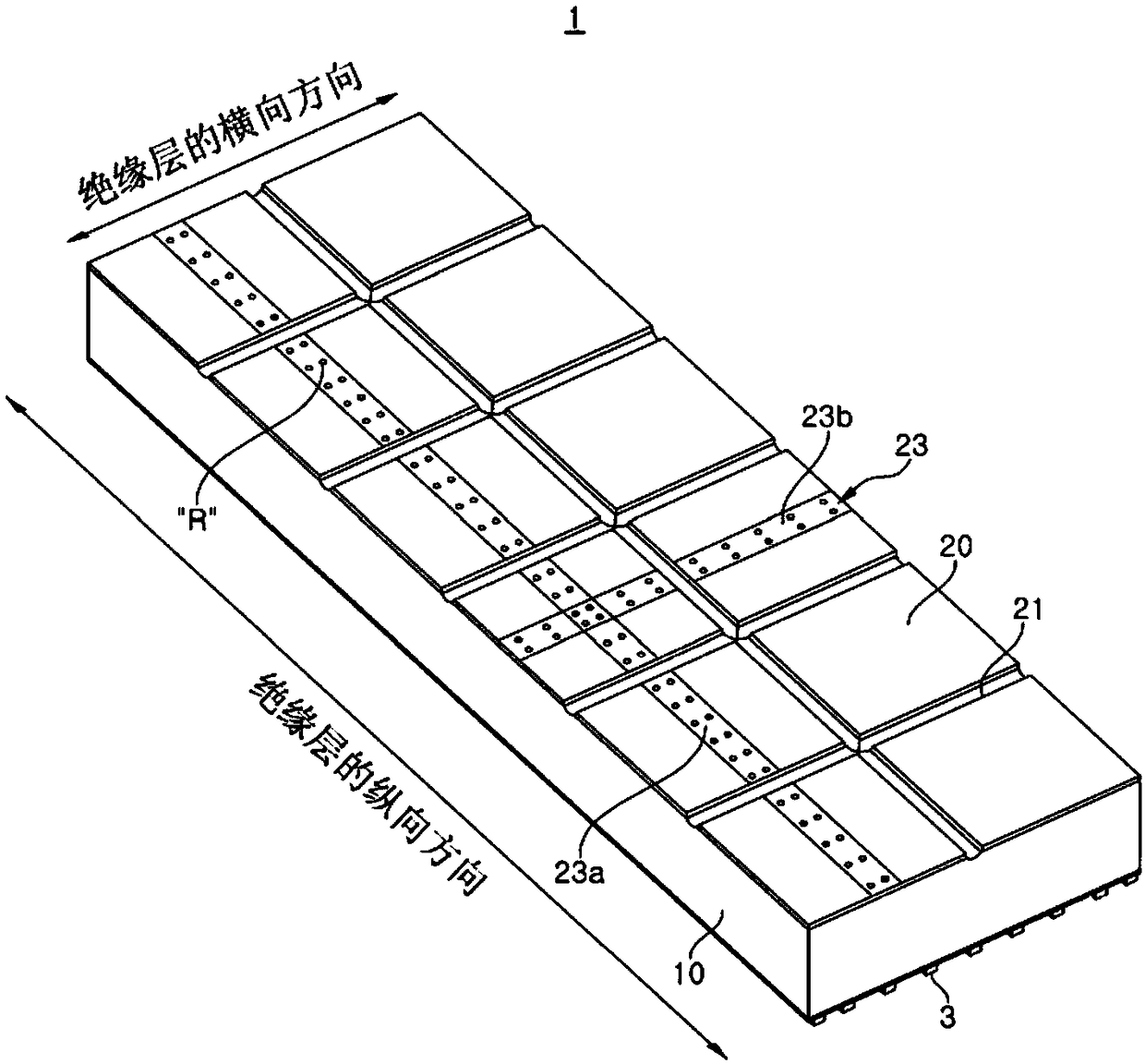

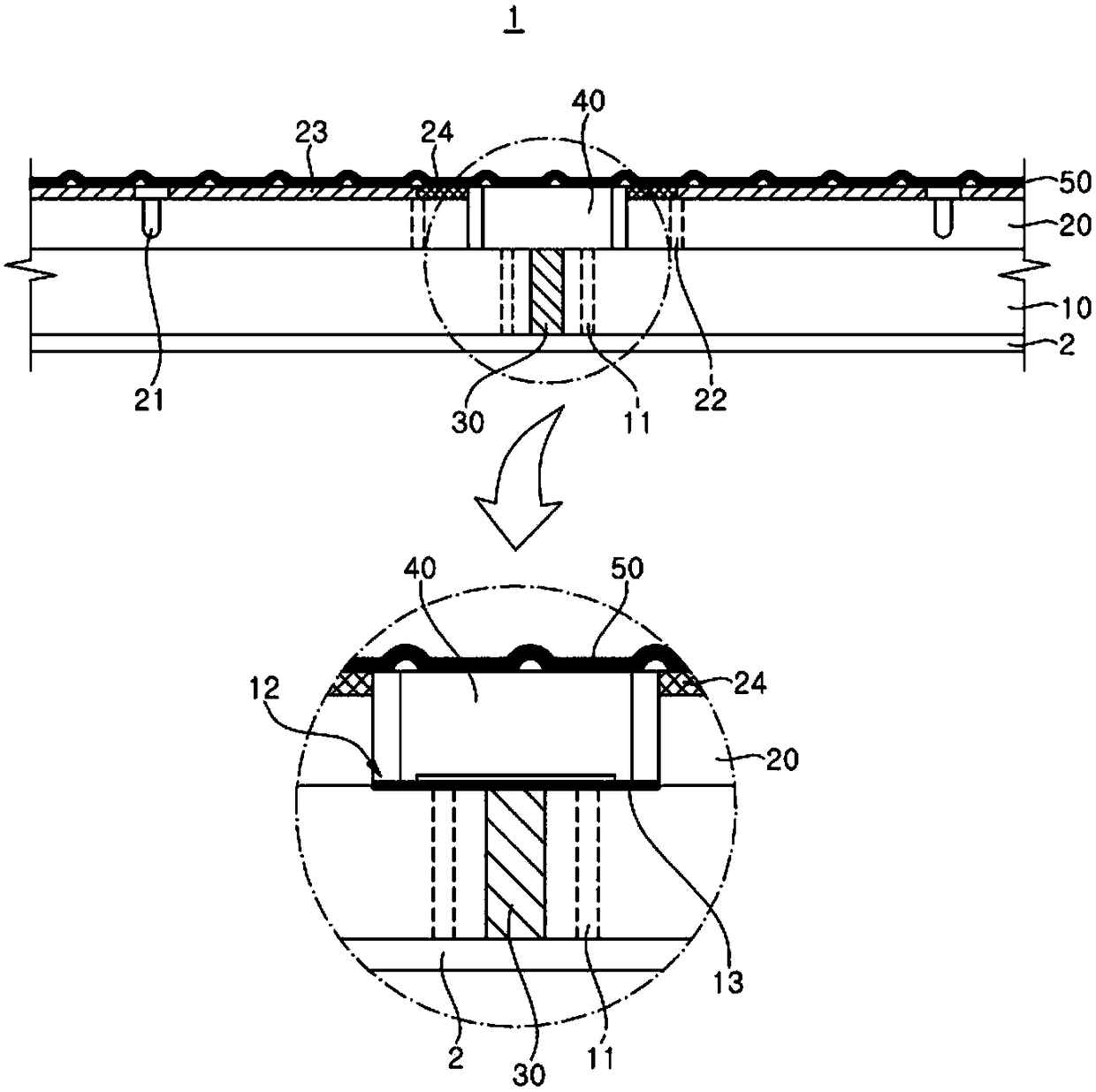

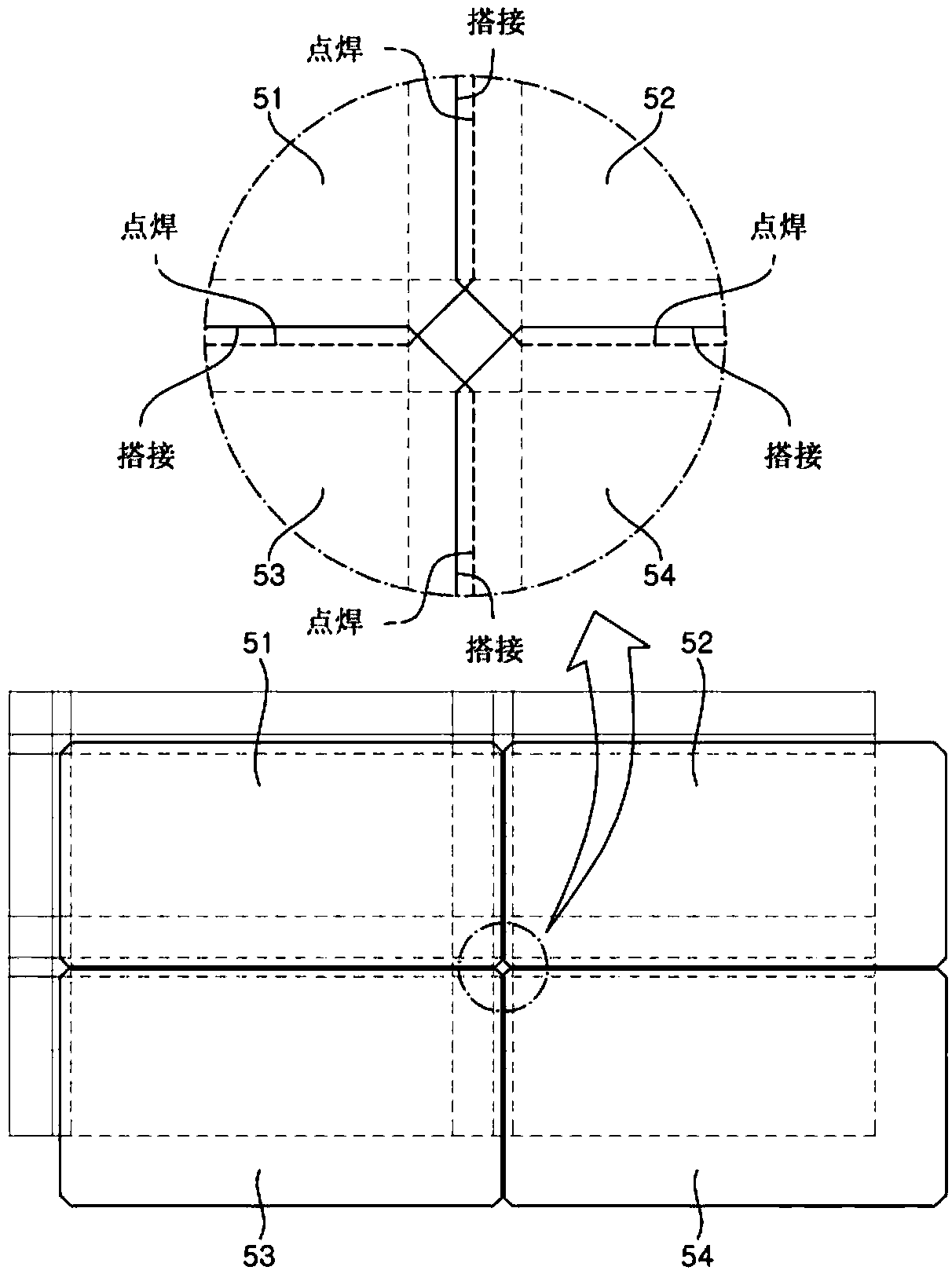

[0062] According to the present invention, a corrugated diaphragm automatic welding system for a membrane-type liquefied gas tank includes: a longitudinal anchoring strip arranged in the longitudinal direction of an insulating layer, the insulating layer including a corrugated diaphragm as a first barrier; a transverse anchor An anchoring strip arranged in the transverse direction of the insulating layer; a cross anchoring strip arranged at the junction between the longitudinal anchoring strips and the transverse anchoring strips, the crossing anchoring strips having a fastening a groove; a vertical support firmly set in the fastening groove; a welding guide connected to the vertical support; and an automatic welding device movable along the welding guide to pair the adjacent The corners of the corrugated diaphragm are lap welded.

[0063] The automatic welding device may include: a main body including a rail in which the welding guide is embedded; a moving wheel provided on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com