Method and device for detecting resonance frequency of linear motor

A resonant frequency, linear motor technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of low use efficiency, the driving signal has a pause, the motor cannot make full use of the driving time, etc., and achieve the effect of improving the use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical scheme and advantages of the embodiments of the present invention clearer, the embodiments of the present invention will be described in detail below with reference to the drawings. However, those skilled in the art can understand that in various embodiments of the present invention, many technical details are put forward in order to make readers better understand the present invention. However, even without these technical details and various changes and modifications based on the following embodiments, the technical solutions claimed by the present invention can be realized.

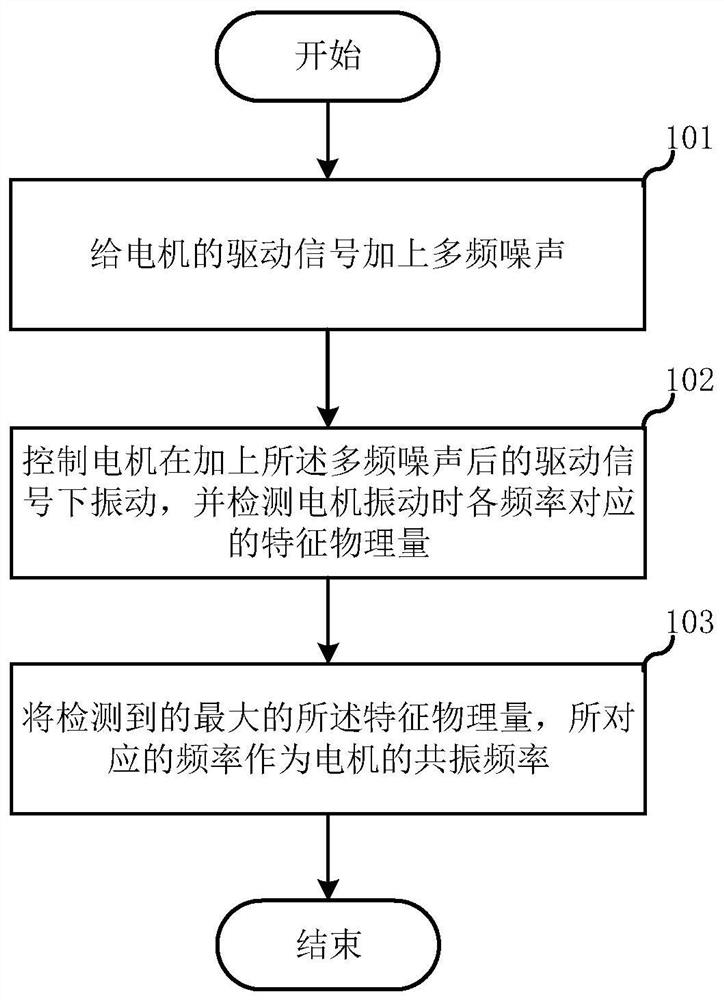

[0023] The first embodiment of the invention relates to a method for detecting the resonance frequency of a linear motor. The core of this embodiment is to add multi-frequency noise to the driving signal of the motor; Controlling the motor to vibrate under the driving signal added with the multi-frequency noise, and detecting characteristic physical quantities...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com