Vehicle front body structure and method for manufacturing thereof

一种前部车身、车辆的技术,应用在车辆部件、下部结构、上部结构等方向,能够解决无法完全实现功能等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the following description, the terms inner, outer, front, rear, transverse, longitudinal, vertical and horizontal refer to the usual orientation of the illustrated element, component or structure assembled on the vehicle structure with the vehicle in a horizontal plane to explain.

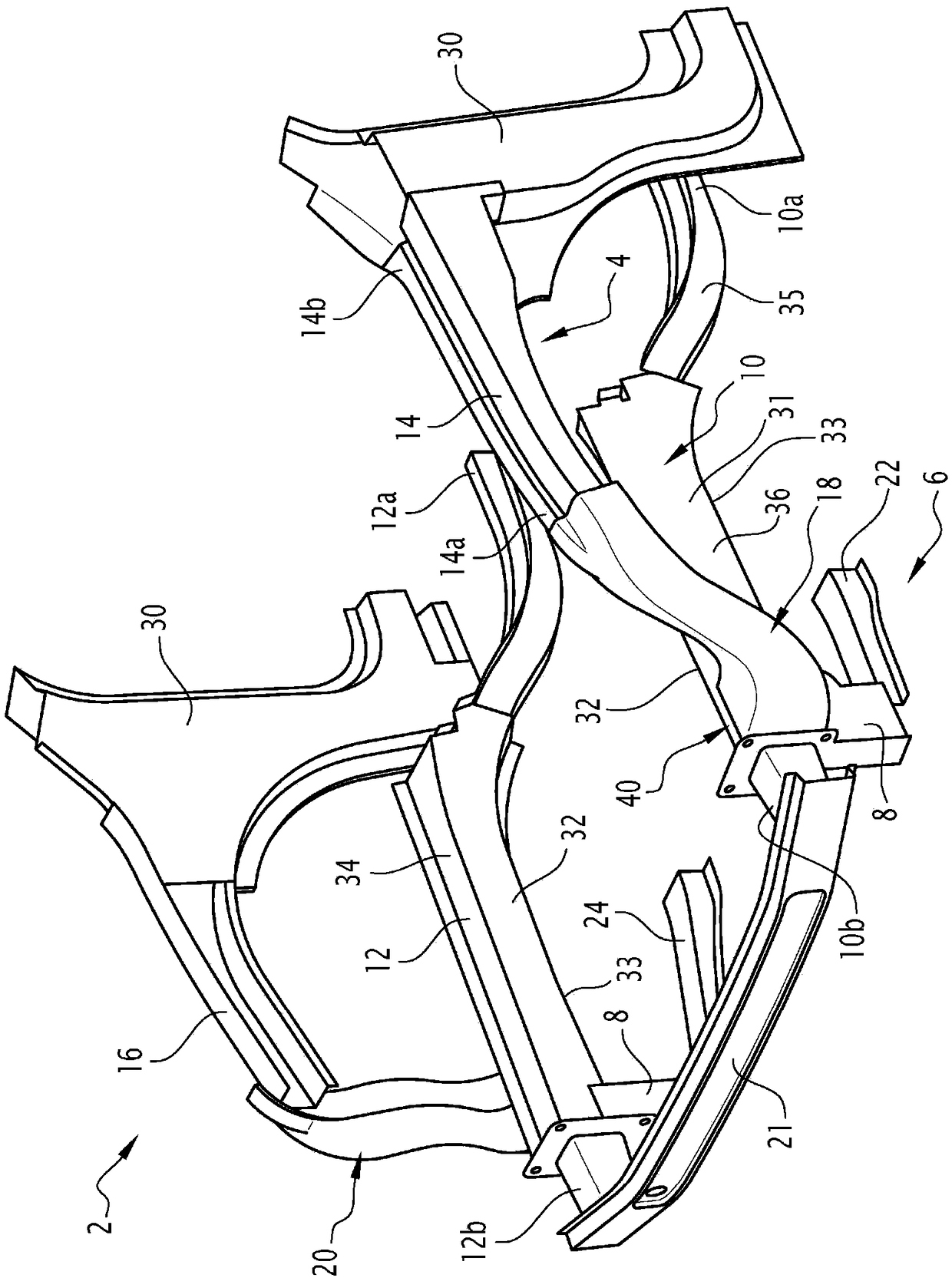

[0017] figure 1 A vehicle front body structure 2 according to an embodiment is shown in . The front body structure 2 of the vehicle can be any kind of front body structure of a four-wheeled vehicle, especially the front body structure of a combination.

[0018] The vehicle front body structure 2 includes an upper frame assembly 4 , a lower frame assembly 6 and a connecting member 8 for joining the upper frame assembly 4 and the lower frame assembly 6 .

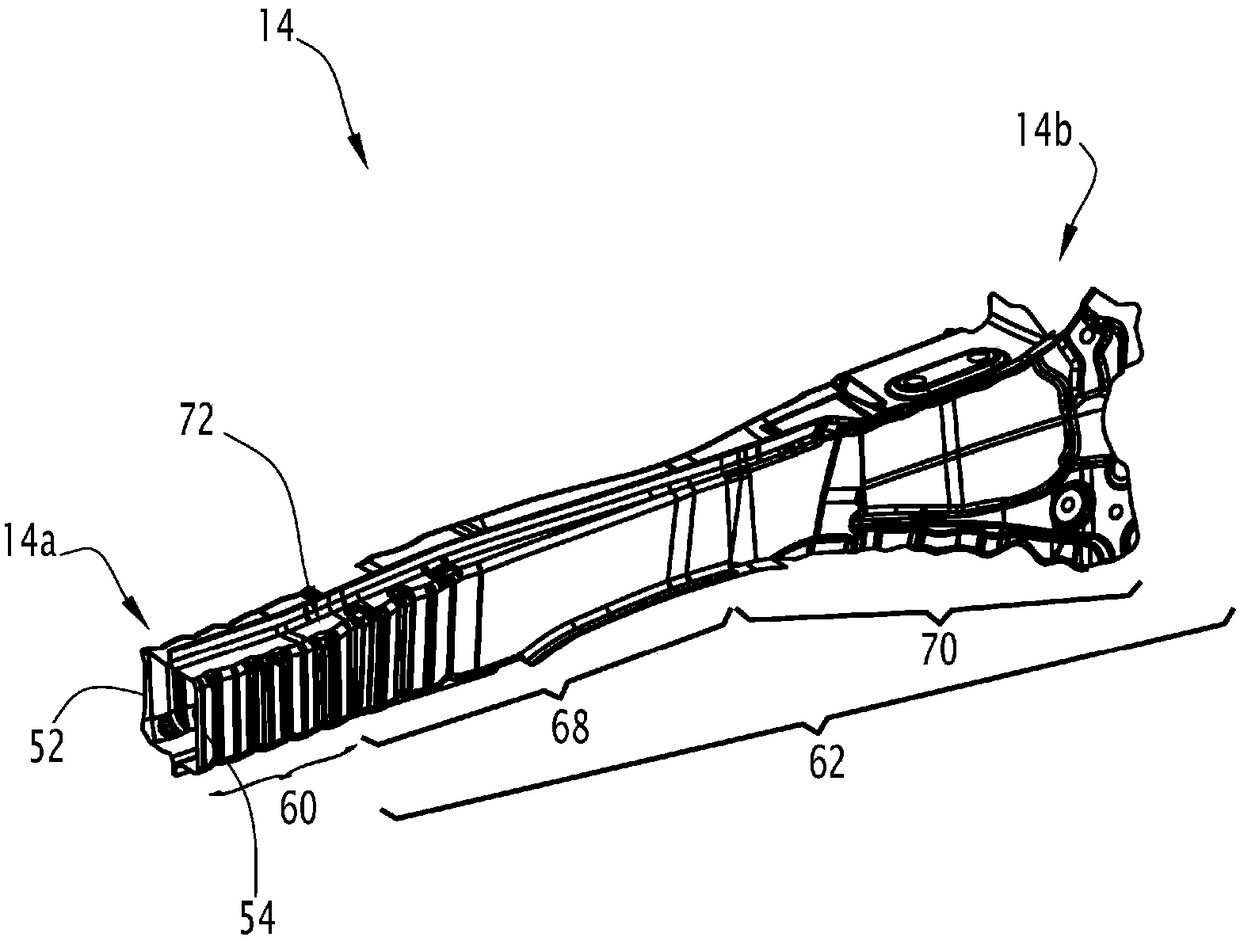

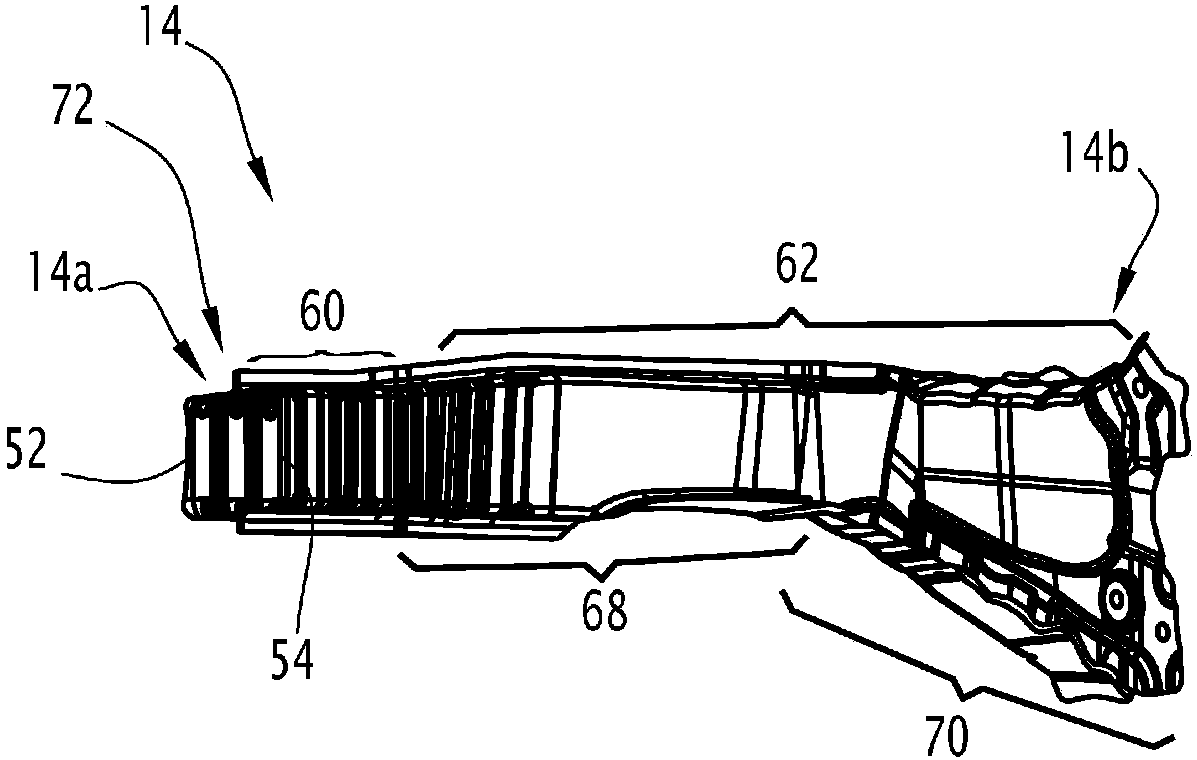

[0019] The upper frame assembly 4 includes two upper side rails 10, 12, two upper fender side rail members 14, 16 and two link members 18, 20 each connecting the upper fender The side rails 14 , 16 are joined to the head rails 10 , 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com