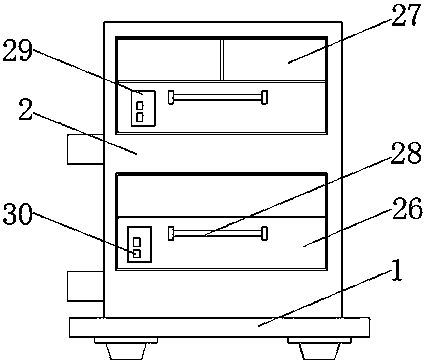

Automobile part storage box with high space utilization rate

A technology of auto parts and utilization rate, which is applied in the field of auto parts, can solve the problem of messy placement of parts, and achieve the effects of easy arrangement, improved efficiency, and simple inventory management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

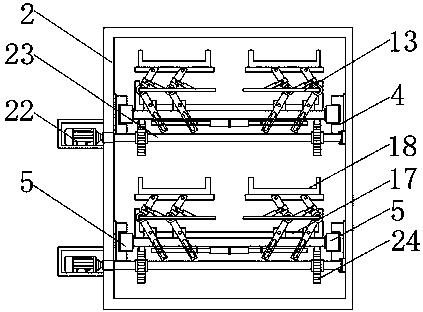

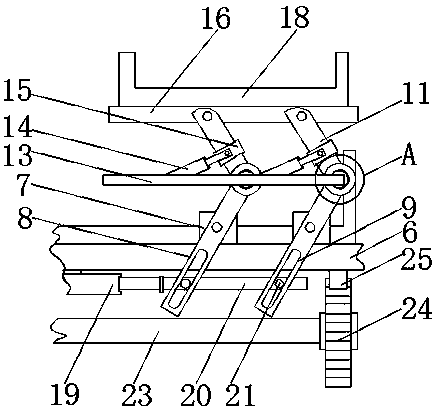

[0024] As the first embodiment of the present invention: the moving block 15 is driven by the first electro-hydraulic rod 14, and the inside of the moving block 15 is slidingly connected with the surface of the linkage rod 11, and the driving rod 8 and the connecting rod 11 are stretched to save space. Two electro-hydraulic rods 19 drive the moving rod 20 and the contact rod 21 to move the surface of the contact rod 21 to slidingly connect with the inner wall of the fixed groove 9, drive the driving rod 8 to rotate, and change the structural space.

[0025] One side of the casing 2 is fixedly connected with a motor 22 through the casing, and the output shaft of the motor 22 is fixedly connected with a rotating rod 23, and one end of the rotating rod 23 penetrates the casing 2 and extends to the inside of the casing 2, so One end of the rotating rod 23 extending to the inside of the casing 2 is rotatably connected to the inner wall of the casing 2 , and a gear 24 is fixedly conn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap