Leather belt buckle

A belt buckle and belt body technology, applied in the direction of belt buckles, fasteners, clothing, etc., can solve the problems of easy damage to the belt body, fastening, loosening, and troublesome adjustment of the tightness, and the process of adjusting the tightness is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

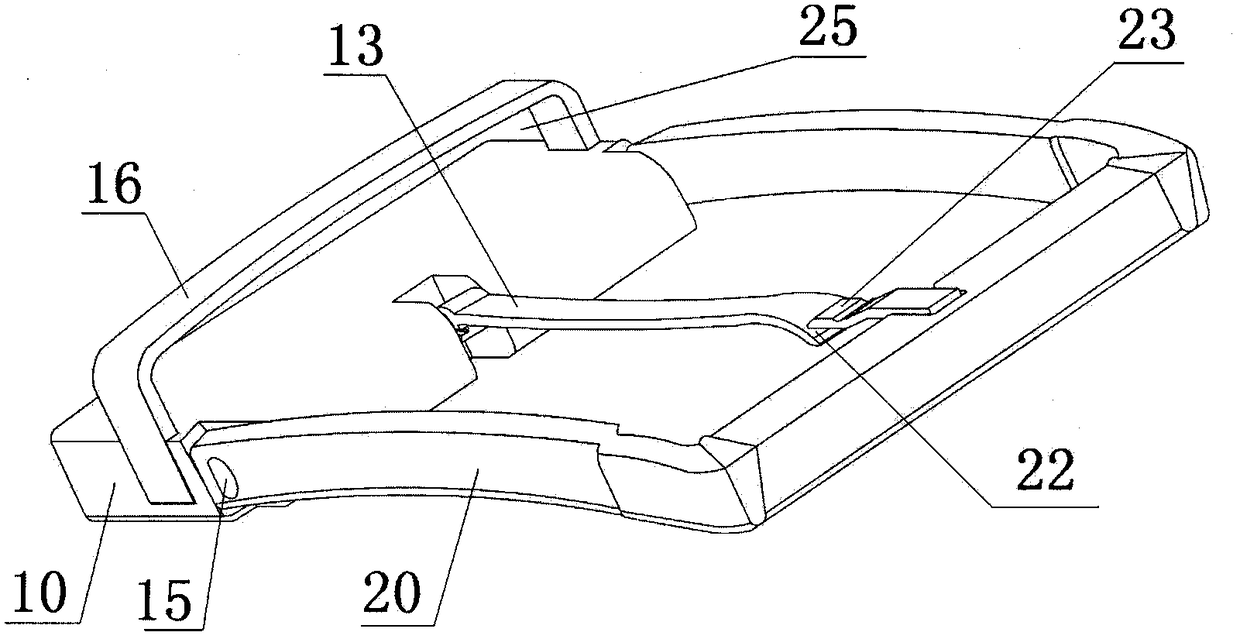

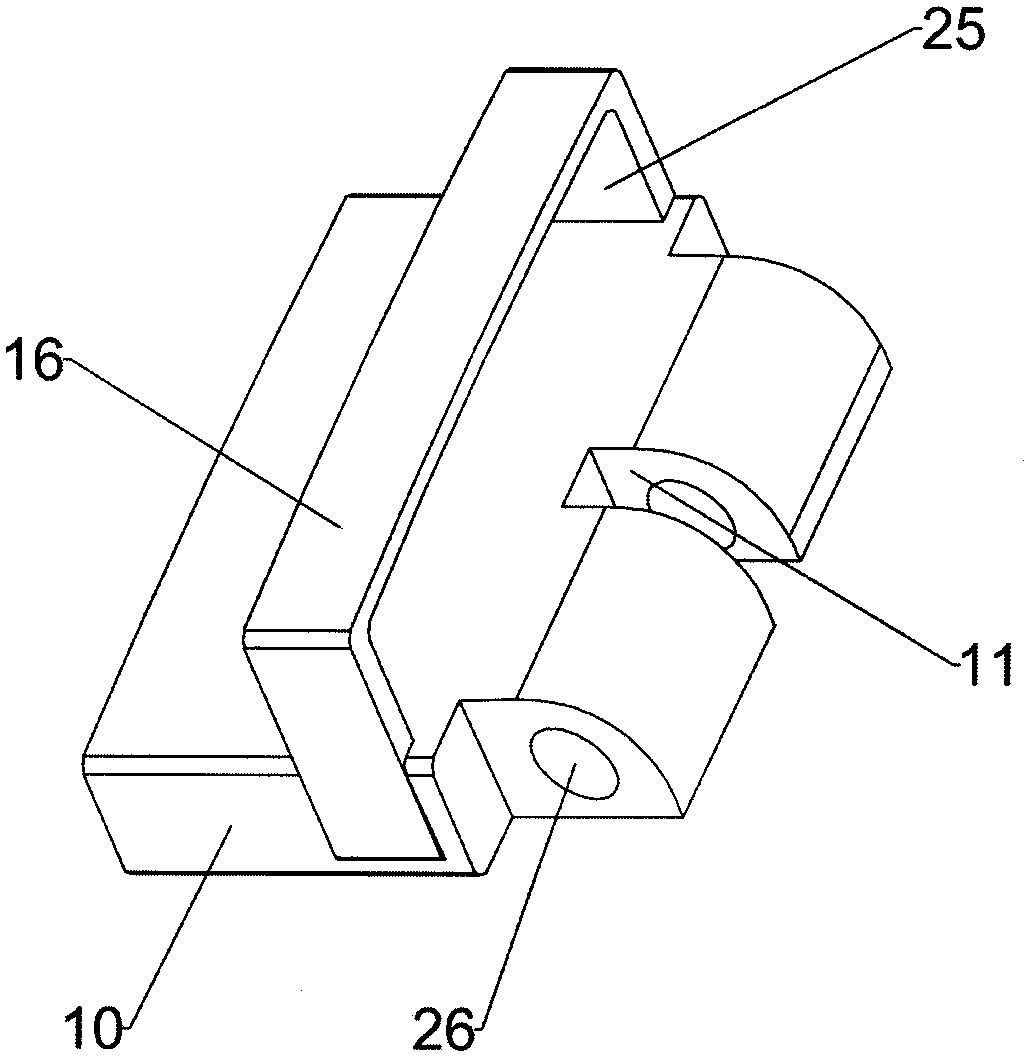

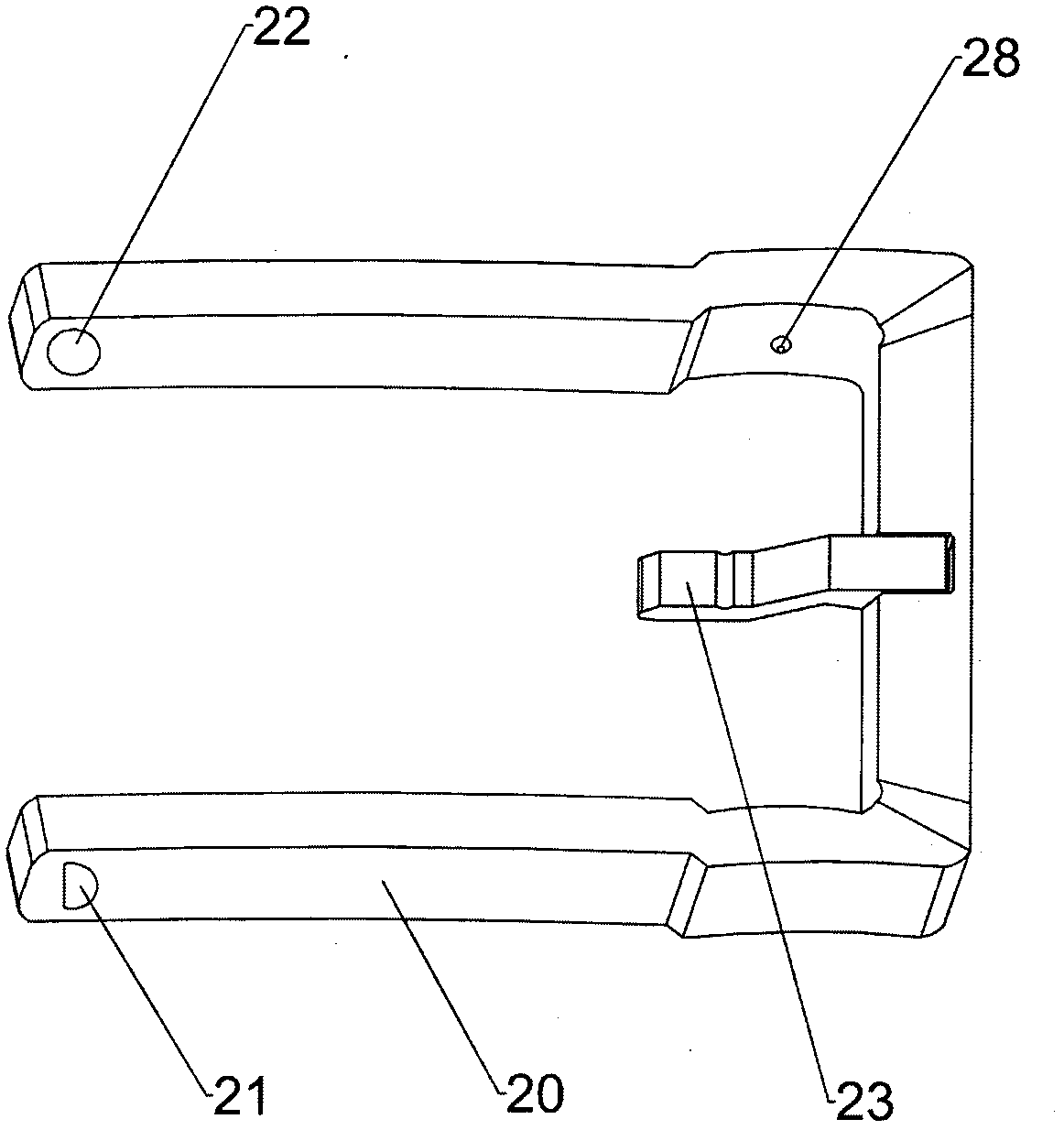

[0041] refer to Figure 1 to Figure 5 , a belt buckle, comprising a body 10, a plate control body 20, a guide needle 13 for guiding the insertion of the belt body, and a limit needle 23 for limiting the position of the belt body; the rear end of the body 10 is provided with a belt clamping portion, and The front end of the main body 10 is connected with a rotating shaft 15 arranged in the left and right directions; the inner surface of the front end of the board control body 20 is provided with a limit pin 23, and the rear end of the board control body 20 is fixedly connected with the rotating shaft 15; the outer surface of the front end of the body 10 is provided with a concave Groove 11, the guide pin 13 is located in the groove 11, the rear end of the guide pin 13 is connected to the rotating shaft 15, the front end of the guide pin 13 is located below the limit pin 23; the rear end of the guide pin 13 is connected with the return spring 12 and the rotating shaft The body 1...

Embodiment 2

[0058] refer to Figure 12 Figure 13 The difference from Embodiment 1 lies in the difference in the structure of the guide needle. In this embodiment, the rotating part 131 of the guide needle 13 can be rotatably connected or fixedly connected. The guide needle 13 can also be a detachable structure. The two connection ends are respectively provided with corresponding grooves and protrusions, and are provided with a first connection hole 136 of the split end, and a second connection hole 137 of the split end, and are connected by the split end rotating shaft 138 and the split end reset spring. 139 connection, the split end rotating shaft 138 diameter is the same as the first connecting hole 136 of the split end and the second connecting hole 137 of the split end, and can freely rotate and reset.

Embodiment 3

[0060] refer to Figure 14 Figure 15 The difference from Embodiment 1 is that a conversion panel 50 is added above the main body of the belt buckle, which is a square sheet structure. The left and right sides of the conversion panel 50 are respectively provided with conversion plug connectors, the left side is the first plug connector 51, and the right side The side is the second plug connector 52, which is respectively provided with a first concave point 53 and a second concave point 54, and is used in conjunction with the first convex point 27 and the second convex point 28 on the left and right sides of the board control body 20, so that the The conversion panel 50 is fixed on the panel control body 20 and can also be easily removed.

[0061] refer to Figure 16 Figure 17 , the difference from Embodiment 1 is that the main body 10 is two cylindrical structures with through holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com