Improved bridge facility

An improved, bridge technology, applied in mechanical equipment, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of monitoring dead corners, waste of mains power, difficulty in adjusting the angle of monitoring devices, etc., to prolong the service life, increase the monitoring range, and have a simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

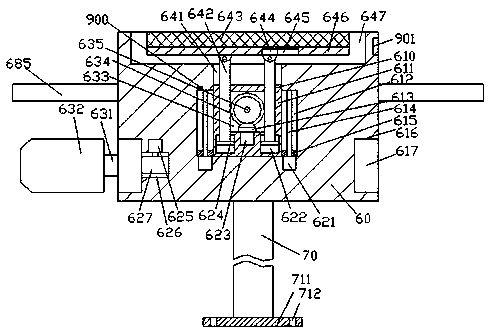

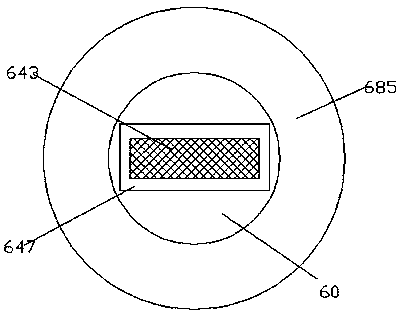

[0015] Such as Figure 1-Figure 3 As shown, an improved bridge facility of the present invention includes a frame 60 and a monitoring probe 632 cooperatingly installed on the frame 60, and a circular shroud 685 is annularly arranged on the outer circumference of the frame 60, thereby It can prevent rainwater from entering the monitoring probe 632 and causing damage. The top end surface of the frame 60 is provided with an installation cavity 647, and the inner wall of the frame 60 on the lower side of the installation cavity 647 is connected with a first A chute 641, the first chute 641 is movably fitted with a sliding table 611, the left and right sides of the sliding table 611 are provided with a push structure and a touch structure, and the inner wall of the sliding table 611 is provided with a first rotary warehouse 633, the first rotating column 635 extending forward and backward in the first rotating housing 633 is connected with the front and rear inner walls of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com