PE conveying hopper

A technology for conveying materials and hoppers, which is applied in the directions of transportation, packaging, loading/unloading, etc. It can solve the problems of not being able to improve the fluidity of materials, and achieve the effect of improving activity and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

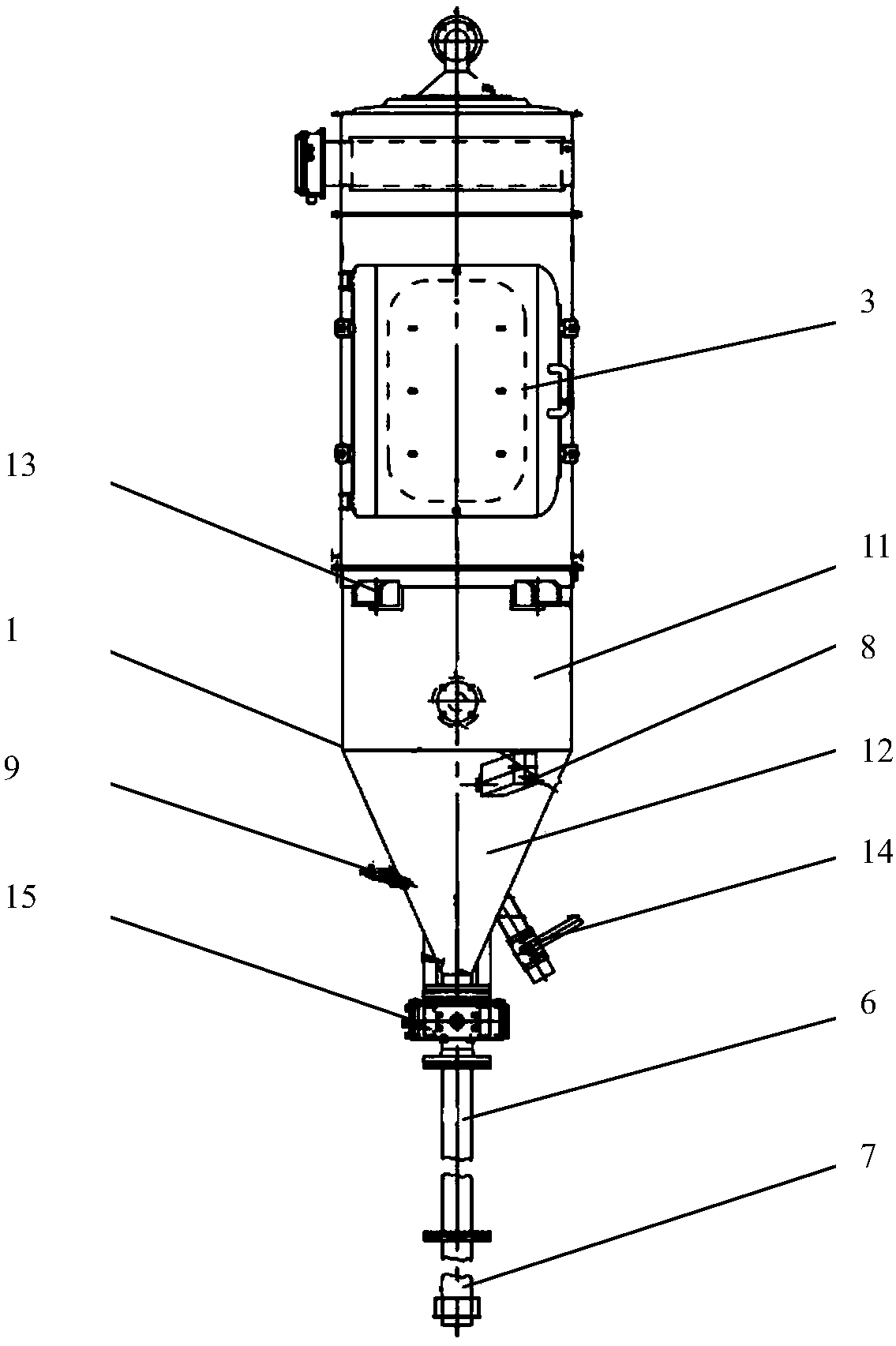

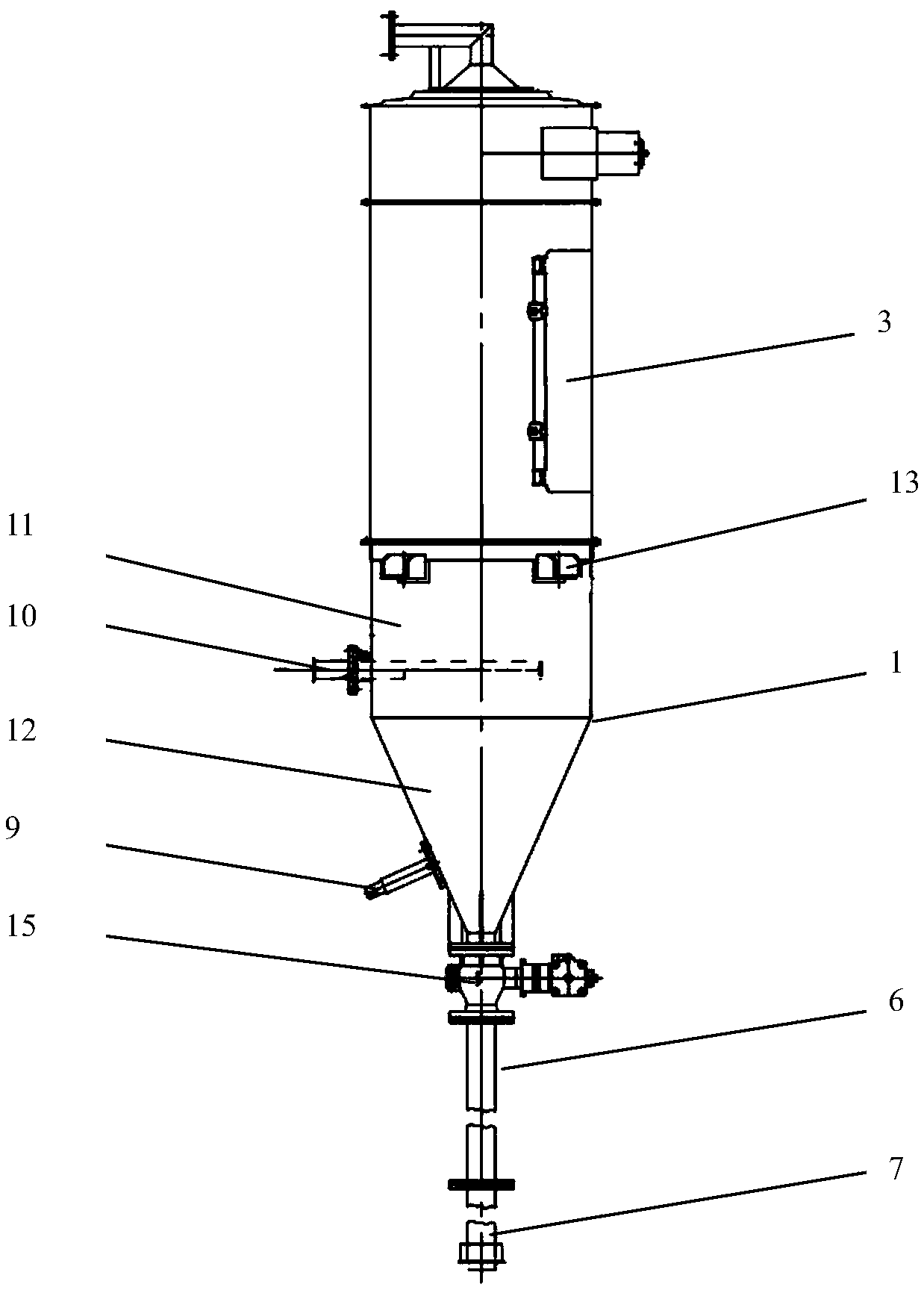

[0025] In a further embodiment of the present invention, the first gas activation device 5 includes an exhaust connecting pipe 51 , and one end of the exhaust connecting pipe 51 communicates with the upper cover 4 .

[0026] In a further embodiment of the present invention, a vibrating level gauge 8 is installed on the outer wall of the hopper 12 .

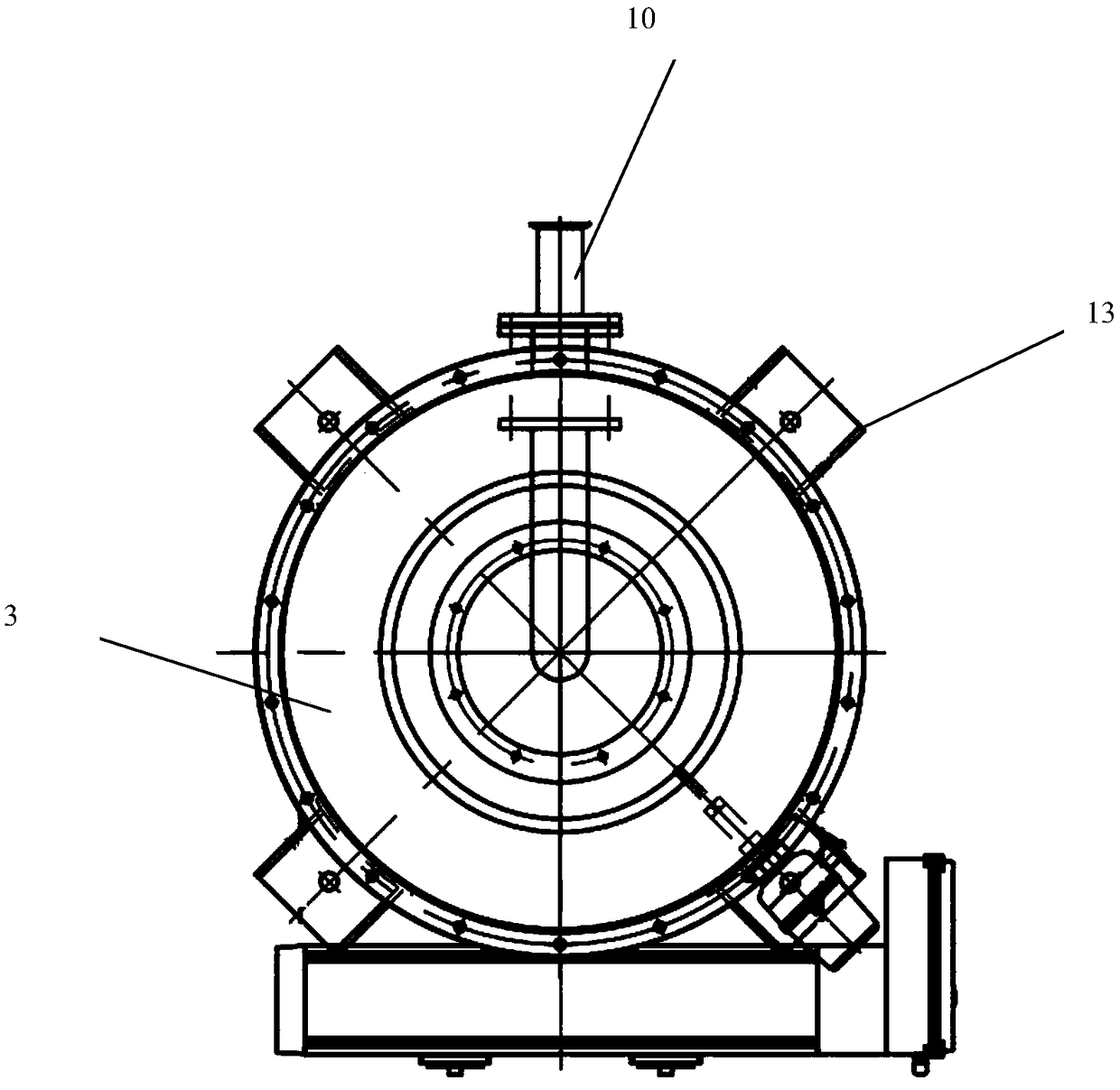

[0027] In a further embodiment of the present invention, a feed tube 10 is installed on the outer wall of the barrel 11 , and one end of the feed tube 10 communicates with the barrel 11 .

[0028] In a further embodiment of the present invention, four lifting lugs 13 are fixed on the outer wall of the hopper 12 .

[0029] In a further embodiment of the present invention, the other end of the second connecting pipe 7 relative to the first connecting pipe 6 has a material outlet.

[0030] In a further embodiment of the present invention, the other end of the feed pipe 10 has a material inlet.

[0031] In a further embodiment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com