Plumb bod fixing device for horizontal impact test

A technology of impact testing and fixing devices, which is applied in the direction of impact testing, measuring devices, and testing of machine/structural components, etc. It can solve problems affecting the implementation of the test, accidents and dangers, and affecting the test, so as to avoid vertical slippage It is difficult to remove the residual glue, quickly and safely change the equipment, and realize the effect of automatic separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

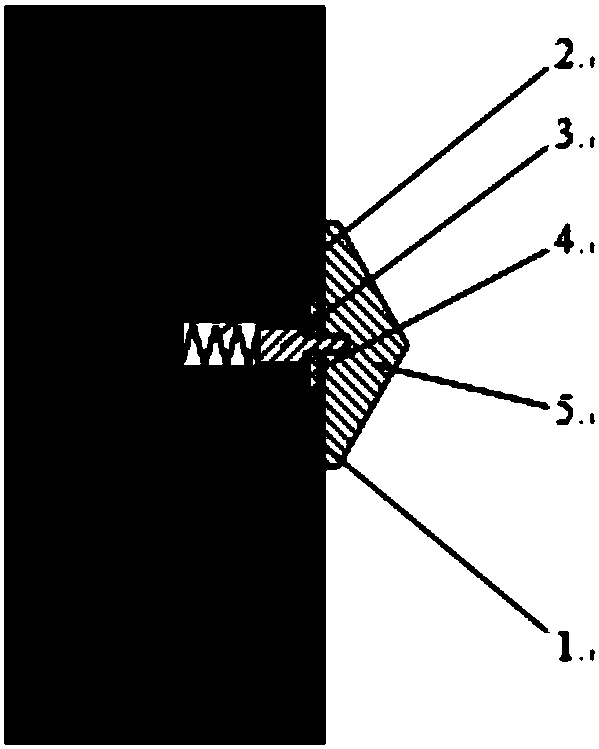

[0015] The present invention designs a lead cone fixing device for horizontal impact tests, and its structural schematic diagram is as follows figure 1 shown.

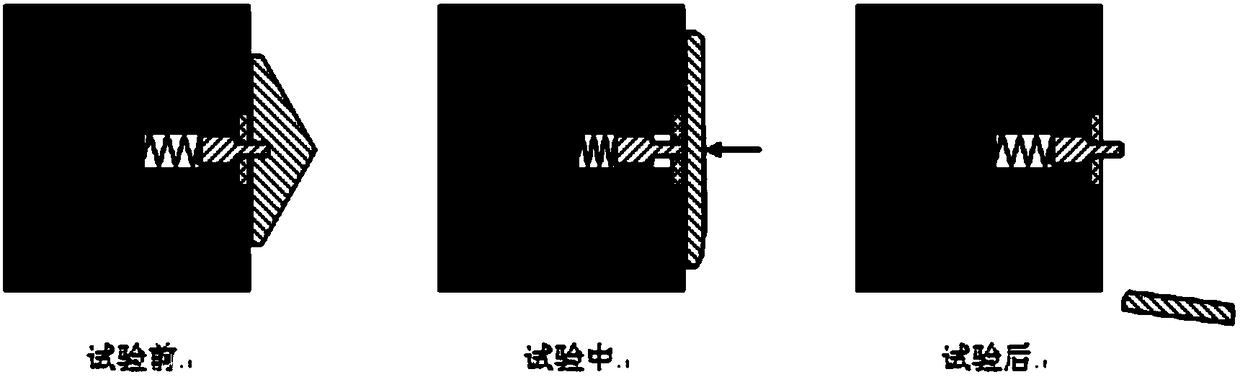

[0016] There are mounting holes on the mounting surface of the waveform generator, combined with figure 2 The test process is shown as follows:

[0017] 1. Before the horizontal impact test, install and fix the lead cone on the installation surface through the thin end of the step pin protruding from the installation surface;

[0018] 2. During the test, the lead cone will be subjected to the impact force from the impact table body and the test piece, and will be deformed under the action of the impact force. At the same time, the step pin is completely pressed into the installation hole by the impact force, so that It is automatically separated from the deformed lead cone, so that the plumb bob f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com