Anti-vibration rubber bushing

A rubber bushing and anti-vibration technology, applied in the direction of high internal friction springs, etc., can solve the problems of limited installation space, limit of load resistance, inability to fully bear load reaction force, etc., and achieve reliable anti-vibration performance and excellent anti-vibration performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

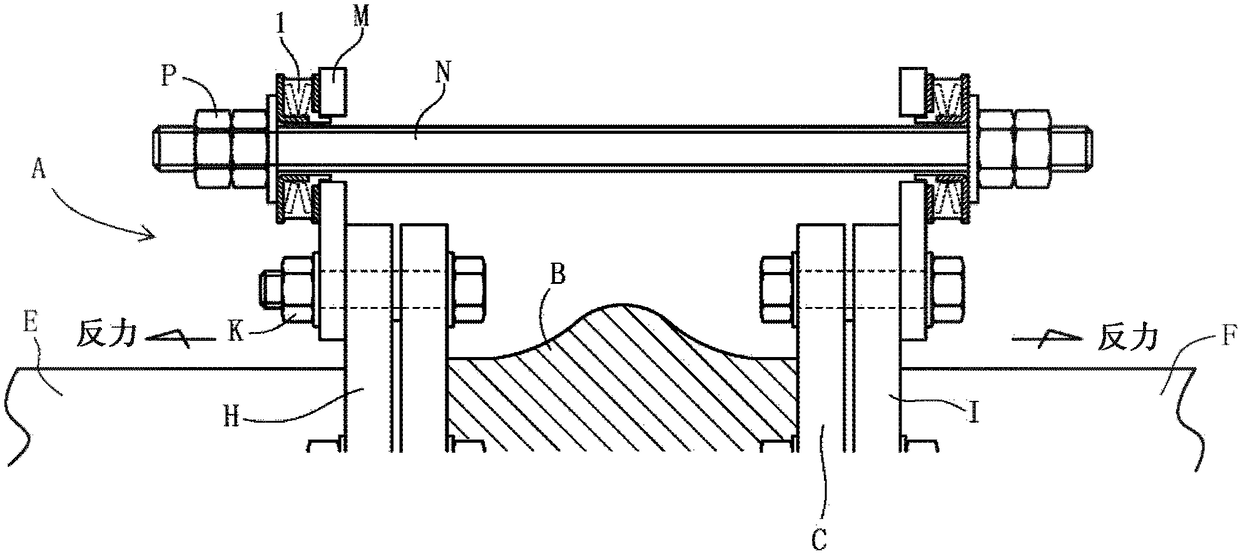

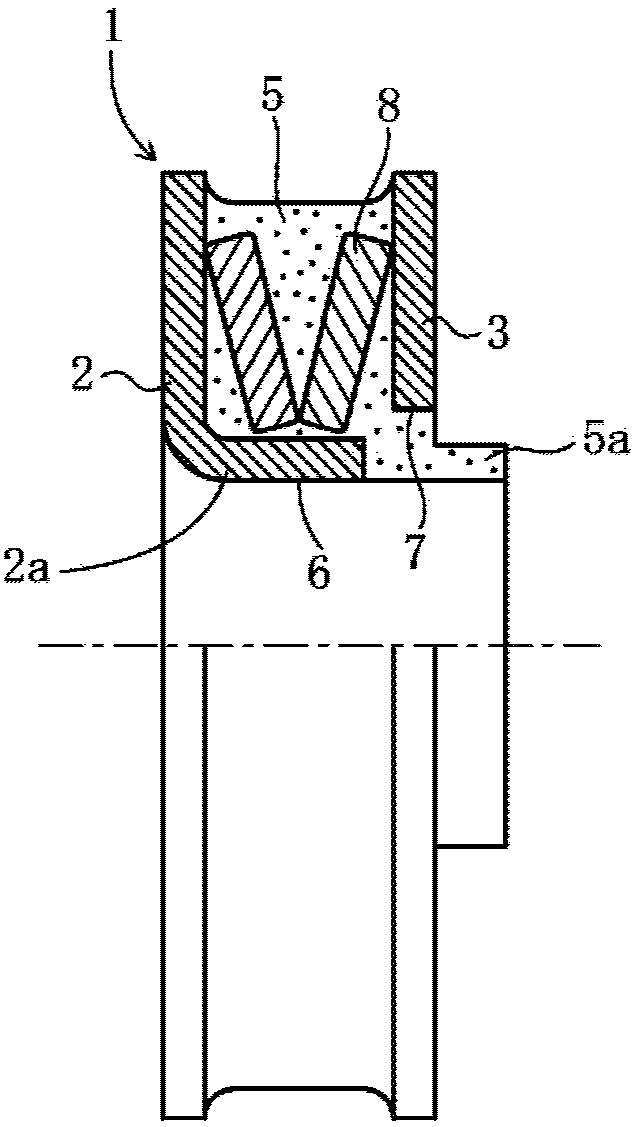

[0043] figure 1 It is a schematic diagram showing the use state (installation state) of the control unit that controls the elongation of the rubber flexible joint. In the figure, A is a flexible joint made of rubber, and the flexible joint A is composed of a cylindrical main body B made of rubber and metal flanges C attached to both ends of the main body. The flange part C abuts against the flange part H and I provided on the opposite ends of the pipes E and F respectively, and is fastened and fixed by bolts and nuts K. The above-mentioned pipes E and F are separated by a predetermined distance on both sides of the flange part C. Configured at intervals. During the above-mentioned fixing, the base end portion of the control unit board M is fixed to the outer surfaces of the flange portions H, I. Holes for control unit bolts are drilled at the front end of the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com