Cleaning blade, process cartridge, and image forming apparatus

A cleaning scraper, flat-shaped technology, applied to the cleaning scraper, can solve the problems of cracking of the surface layer, reduction of tracking of cleaning parts, etc., and achieve the effect of suppressing the reduction of tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

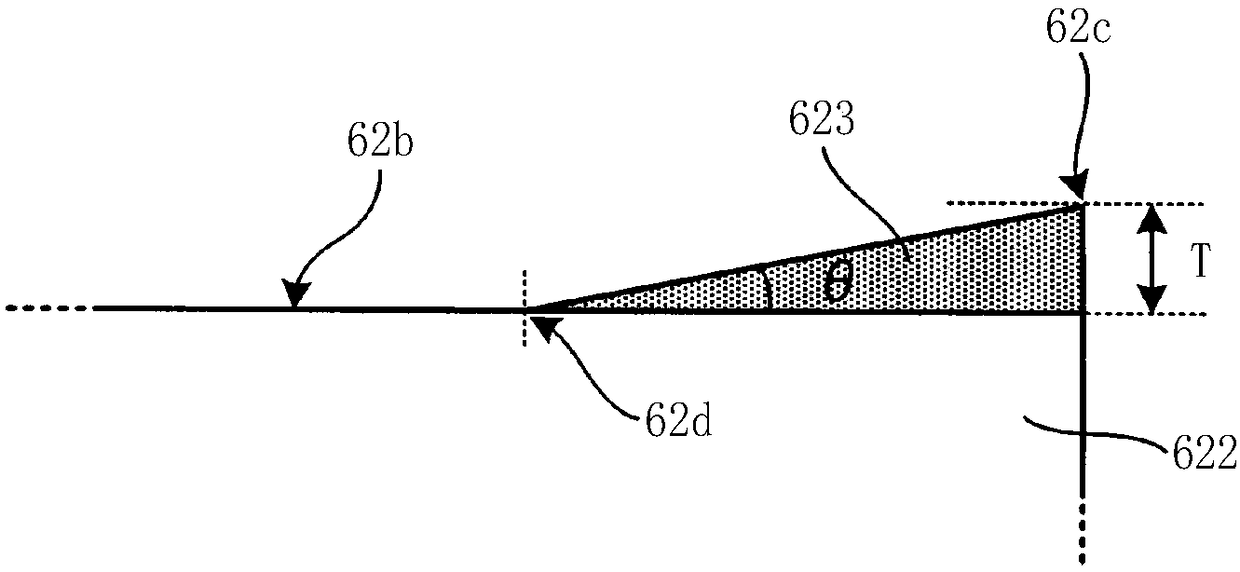

[0235] The coating liquid 1 was sprayed on the surface of the base material made of urethane rubber with a mask width of 5 mm.

[0236] The spray gun used was SV-91 manufactured by SANEITECH Co., Ltd., and the tip of the gun faced the center of the coating portion, and the distance from the tip of the gun to the surface of the sheet was 60 mm. The spray gun sets the spray speed of the coating liquid to

[0237] 0.04cc / min, the atomization pressure is set to 0.05MPa, and the surface of the sheet is repeatedly reciprocated in the long direction at 5mm / sec for coating.

[0238] Next, remove the mask, and use an ultraviolet irradiation device (ECS-1511U manufactured by EYE GRAPHICS CO., LTD.) to perform secondary ultraviolet irradiation (transport speed 54mm / min, cumulative illuminance 4000mJ / cm 2 ), and thereafter, drying was performed at an internal temperature of 100° C. for 15 minutes using a heat dryer to form a surface layer.

[0239] The central part of the region where t...

Embodiment 2~3

[0258] As shown in Table 1, the width of the mask was changed to form a surface layer. In the same way as in Example 1, cleaning blades 2 and 3 were produced respectively, and in the same way as in Example 1, they were installed in an image forming apparatus and a paper passing test was carried out. Make an evaluation.

[0259] Table 1 shows the shape and hardness value of the formed surface layer, and the evaluation results.

Embodiment 4~5

[0261] As shown in Table 1, the width of the mask was changed, and the surface layer was formed using the coating solution 2. In the same manner as in Example 1, cleaning blades 4 and 5 were produced, respectively, and were installed in an image forming apparatus in the same manner as in Example 1. A paper pass test was implemented and evaluated.

[0262] Table 1 shows the shape and hardness value of the formed surface layer, and the evaluation results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Martens hardness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com