Motor cooling structure, power motor and electric drive system

A technology of motor cooling and liquid cooling structure, applied in electric components, cooling/ventilation devices, magnetic circuit shape/style/structure, etc., can solve the problems of rotor temperature rise, impact on bearing life, bearing overtemperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. In the drawings, the same reference numerals represent the same or corresponding technical features.

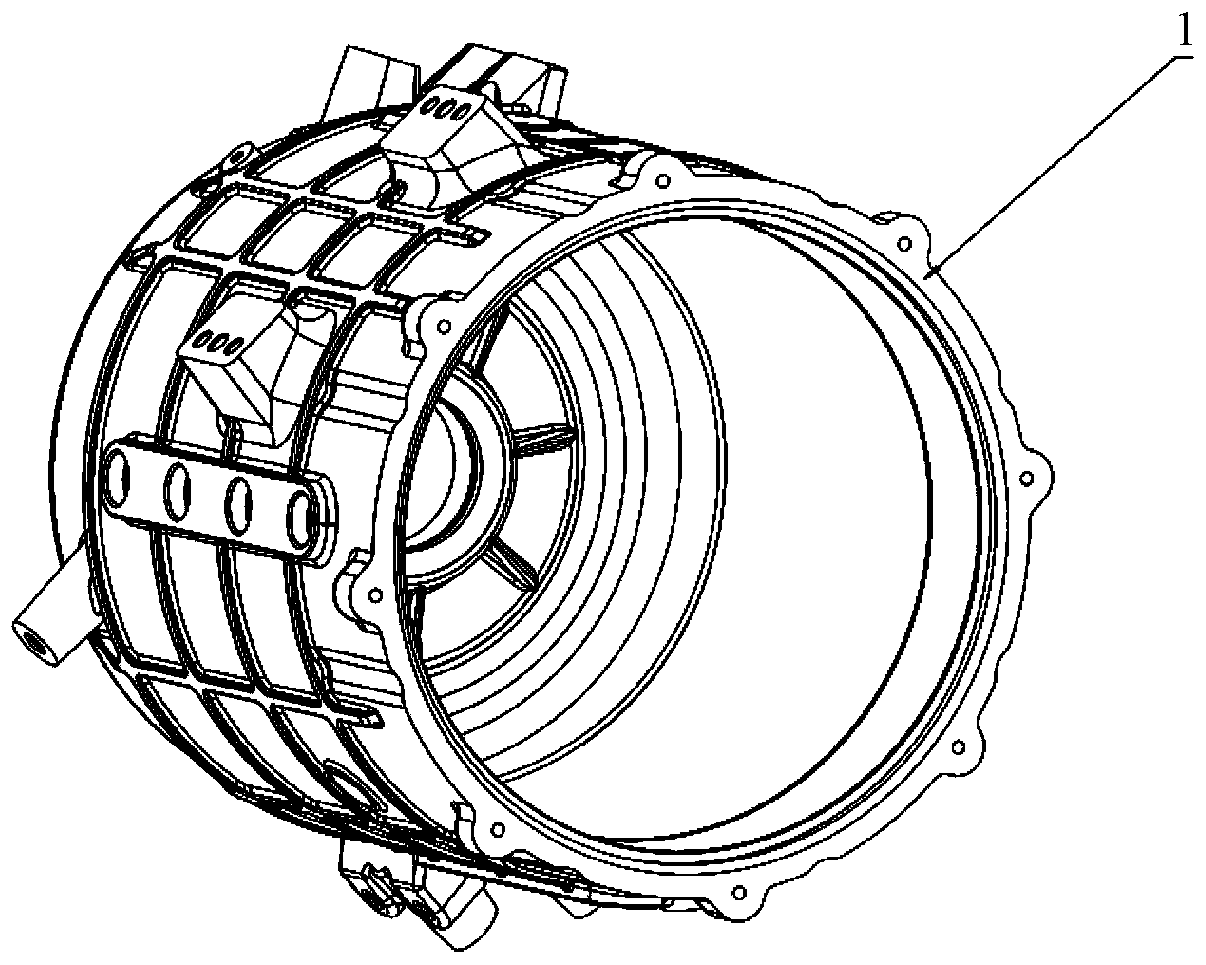

[0026] figure 1 It is a schematic cross-sectional view of an embodiment of the power motor according to the present invention. It can be seen from the figure that the power motor includes a motor casing 1, a stator winding 2, a stator core 3, a motor end cover 5, a rotor core 6, and the like.

[0027] In the figure, the stator winding 2 is embedded in the stator core 3, the stator core 3 is fitted on the motor casing 1 by shrink fitting, and the motor end cover 5 and the motor casing 1 are connected together by bolts. The motor casing 1 may have a built-in stator liquid cooling structure. When the motor is running, the coolant circulates in the stator liquid cooling structure to take away the heat from the motor stator. The cooling liquid her...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap