Pressure maintaining device and equipment

A pressure-holding device and indenter technology, which is used in mechanical equipment, metal processing equipment, presses, etc., can solve problems such as unsatisfactory pressure-holding effect and uneven force on the material to be held.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

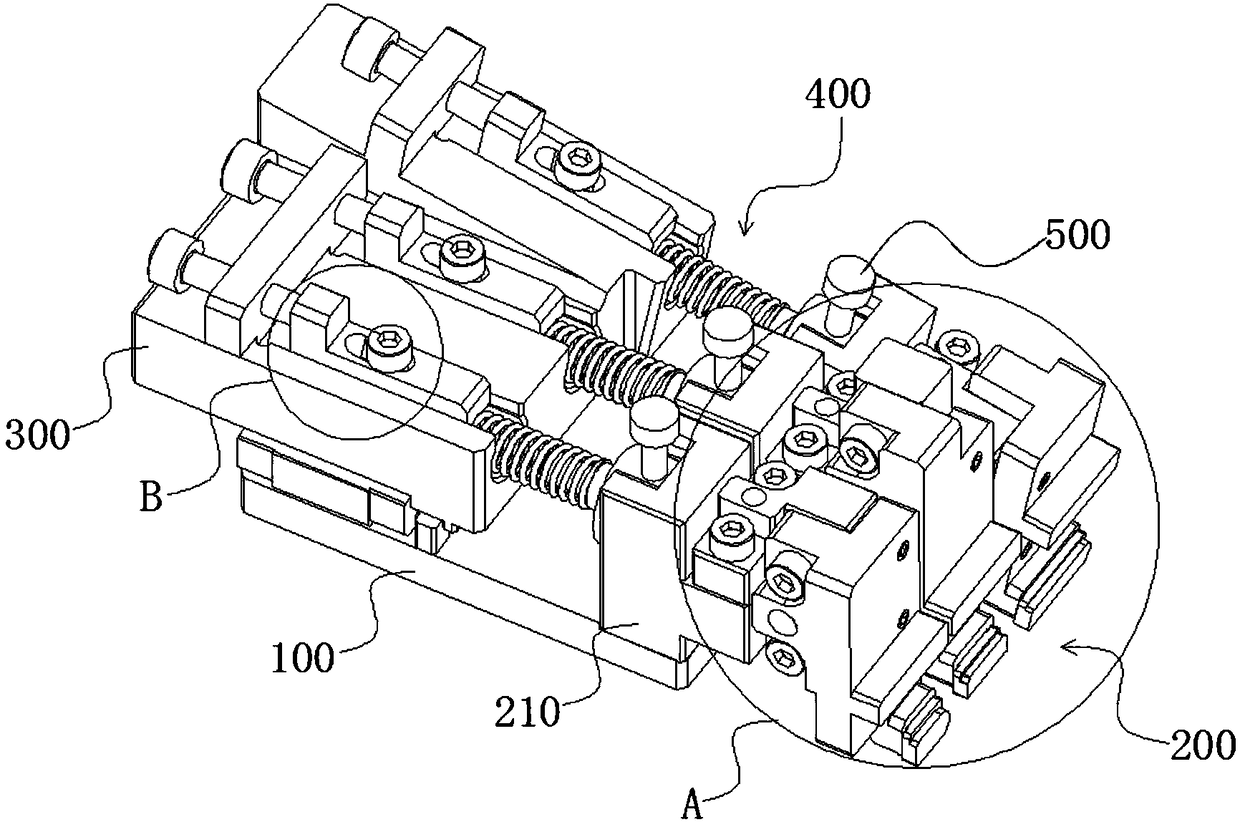

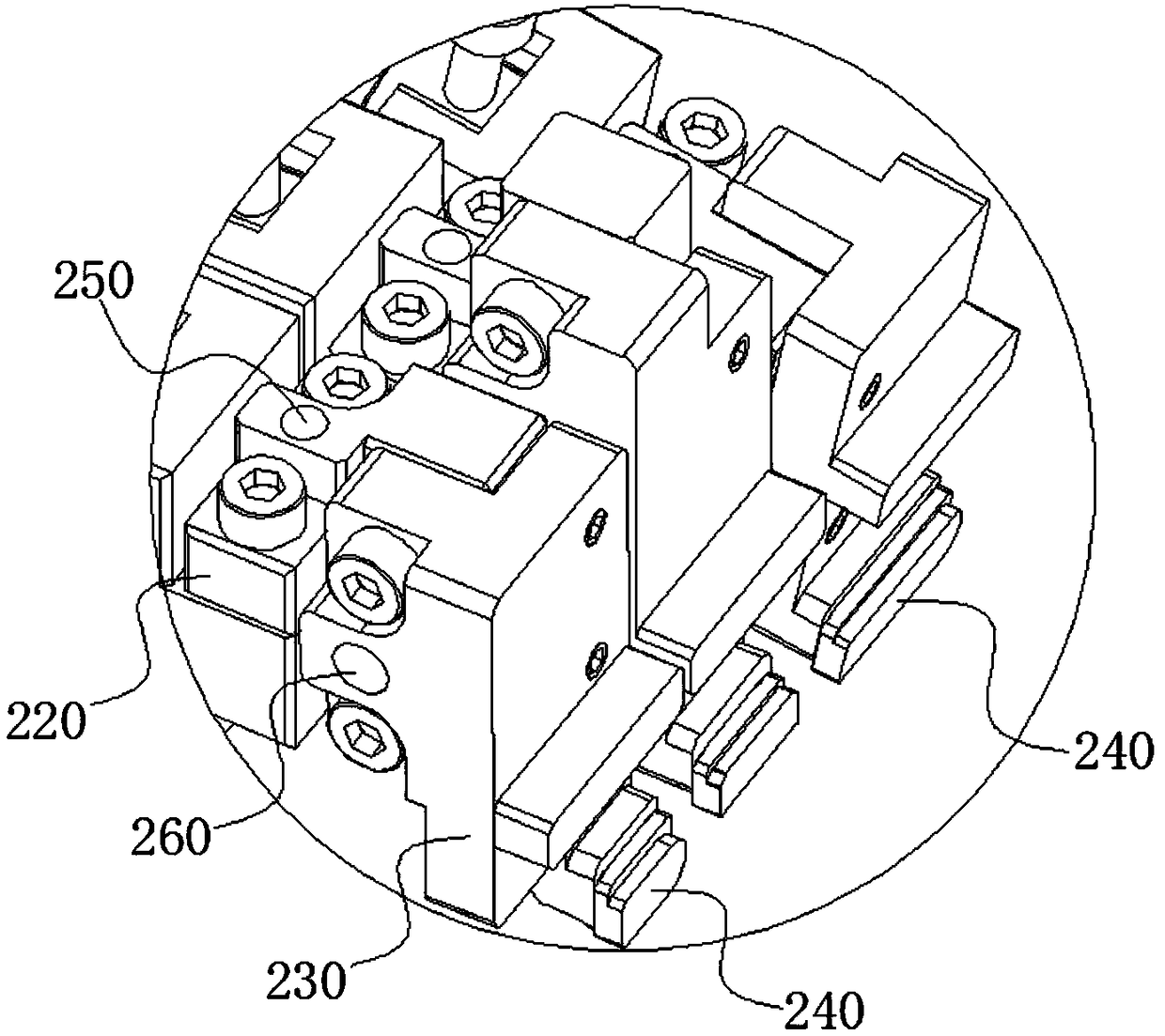

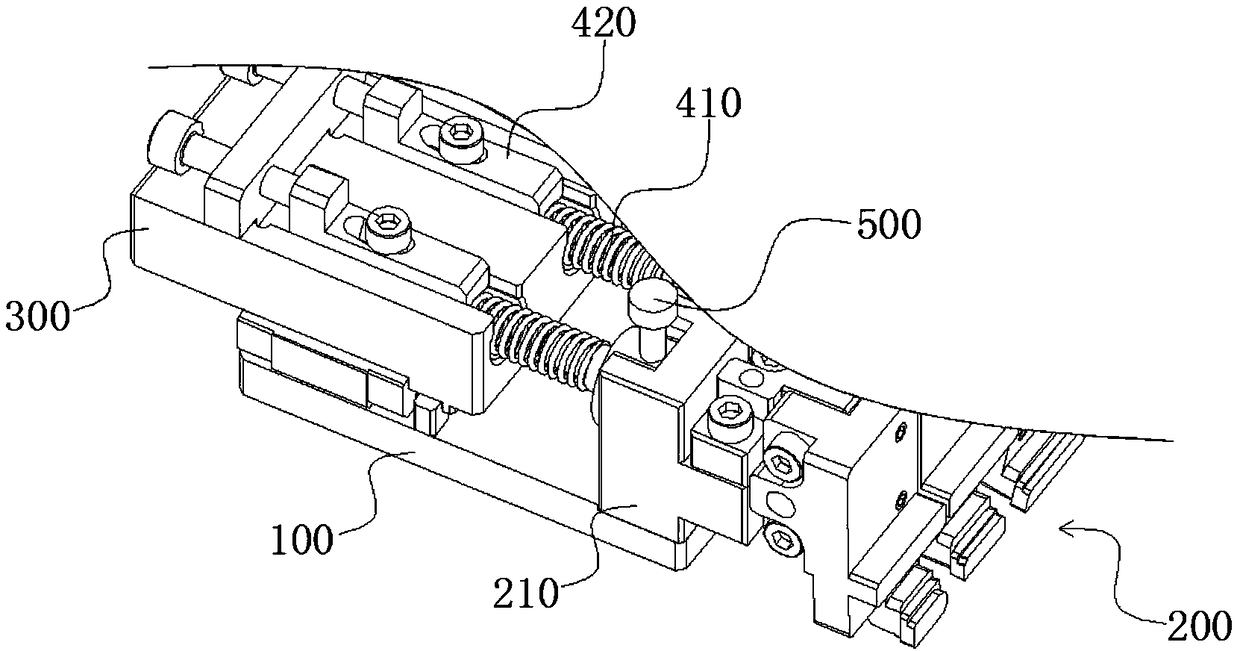

[0040] Such as Figure 1 to Figure 4 As shown, the first embodiment provides a pressure maintaining device, including: a connection base 100, a pressure maintaining head assembly 200 connected to the connection base 100, and a power mechanism for driving the pressure maintaining head assembly 200; wherein, the pressure maintaining head The assembly 200 includes a fixed block 210 fixed on the connection base 100, an intermediate block 220 connected to the fixed block 210, a pressure maintaining head seat 230 connected to the intermediate block 220, and a pressure maintaining head seat 230 connected to the pressure maintaining head seat 230. The head 240; the middle block 220 and the fixed block 210 are hinged through the first pin shaft 250, the pressure maintaining head seat 230 and the middle block 220 are hinged through the second pin shaft 260, and the first pin shaft 250 and the second pin shaft 260 are vertically arranged. The fixed block 210 , the middle block 220 and th...

Embodiment 2

[0069] Embodiment 2 provides a pressure-holding device, including: a product carrier for fixing products and the pressure-holding device in Embodiment 1 above.

[0070] The above-mentioned pressure-holding device is provided in the pressure-holding device, wherein the specific structure, connection relationship, working process and beneficial effects of the pressure-holding device have been described in detail in the above text, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com