Pressure maintaining jig, machining method of cover plate assembly, cover plate assembly and terminal device

A technology of terminal equipment and processing methods, applied in branch equipment, mechanical equipment, connecting components, etc., can solve problems that affect user experience and brand image, degumming and separation, and affect the consistency of the pressure-holding effect of glass cover components, etc., to achieve The effect of improving product quality and user experience, improving consistency, and reducing the risk of degumming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

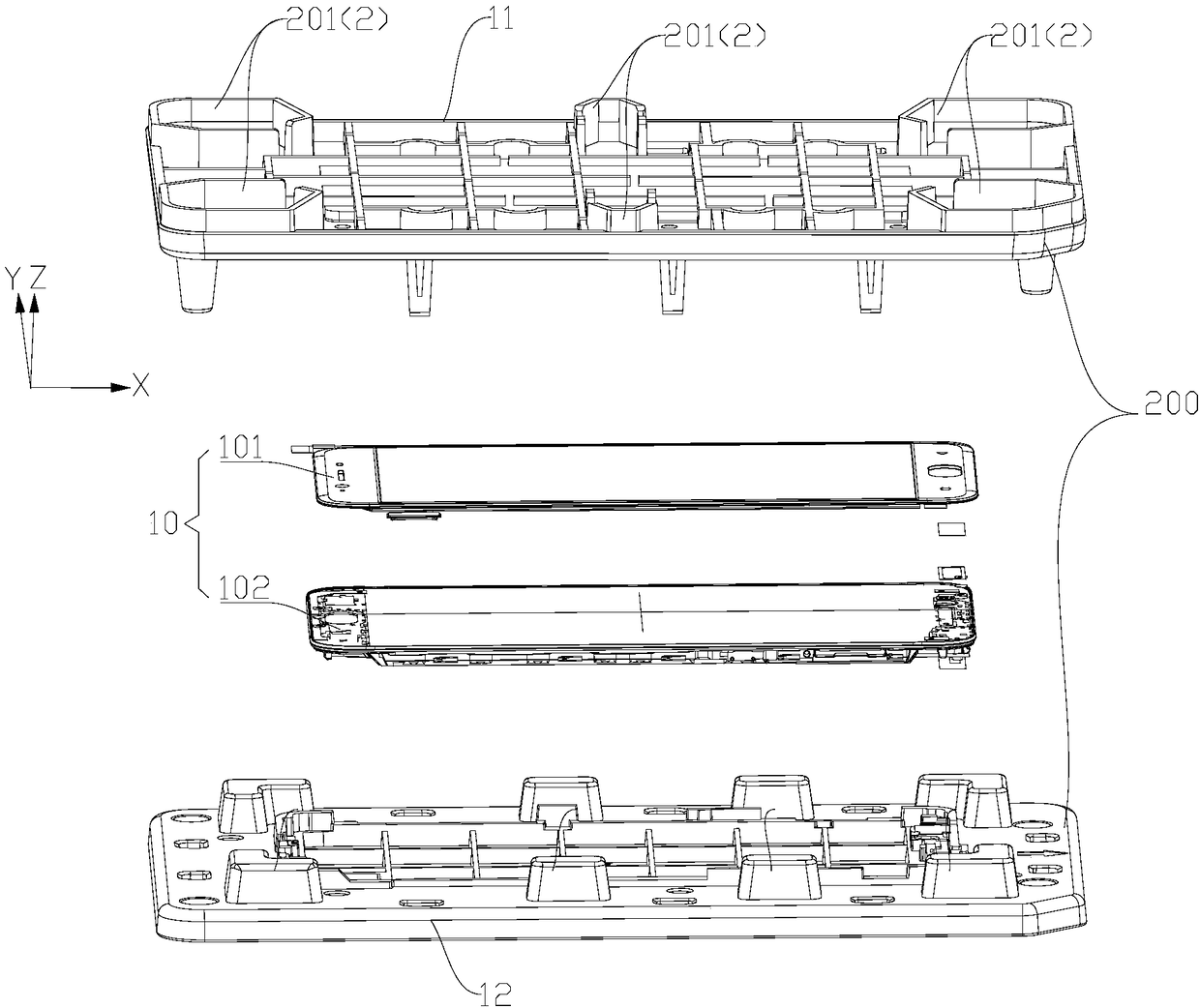

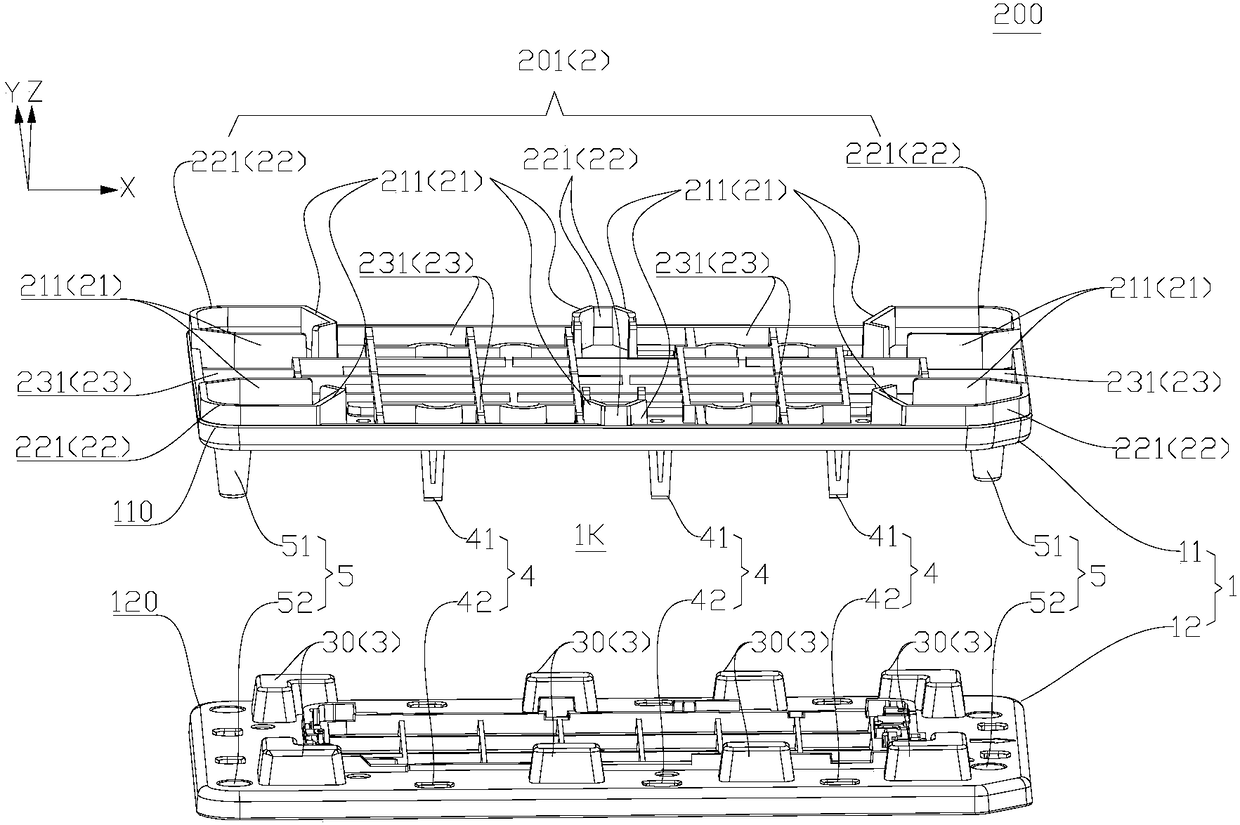

[0057] In this embodiment one, refer to Figure 1-Figure 3 The limiting structure 2 is disposed on the first cover 11 and defines a limiting groove 23 located on the side of the first cover 11 away from the second cover 12 for limiting the clip 6 . Here, for a clearer description, the limiting structure 2 provided on the first cover 11 is marked as "first limiting structure 201", and the limiting structure 2 located on the side of the first cover 11 away from the second cover 12 is The positioning groove 23 is marked as "the first limiting groove 231".

[0058] That is to say, the first limiting structure 201 is provided on the first cover body 11, that is, the first limiting structure 201 is integrally formed with the first cover body 11, or installed on the first cover body 11, the first limiting structure 201 The positioning structure 201 defines a first limiting groove 231, the first limiting groove 231 is located on the side of the first cover 11 away from the second cov...

Embodiment 2

[0062] In the second embodiment, refer to Figure 4-Figure 5 The limiting structure 2 is disposed on the second cover 12 and defines a limiting groove 23 located on a side of the second cover 12 away from the first cover 11 for limiting the clip 6 . Here, for a clearer description, the limiting structure 2 provided on the second cover 12 is marked as "second limiting structure 202", and the limiting structure 2 located on the side of the second cover 12 away from the first cover 11 is The positioning slot 23 is marked as "the second limiting slot 232".

[0063] That is to say, the second limiting structure 202 is provided on the second cover body 12, that is, the second limiting structure 202 is integrally formed with the second cover body 12, or is installed on the second cover body 12, and the second limiting structure 202 The positioning structure 202 defines a second limiting groove 232, the second limiting groove 232 is located on the side of the second cover 12 away fro...

Embodiment 3

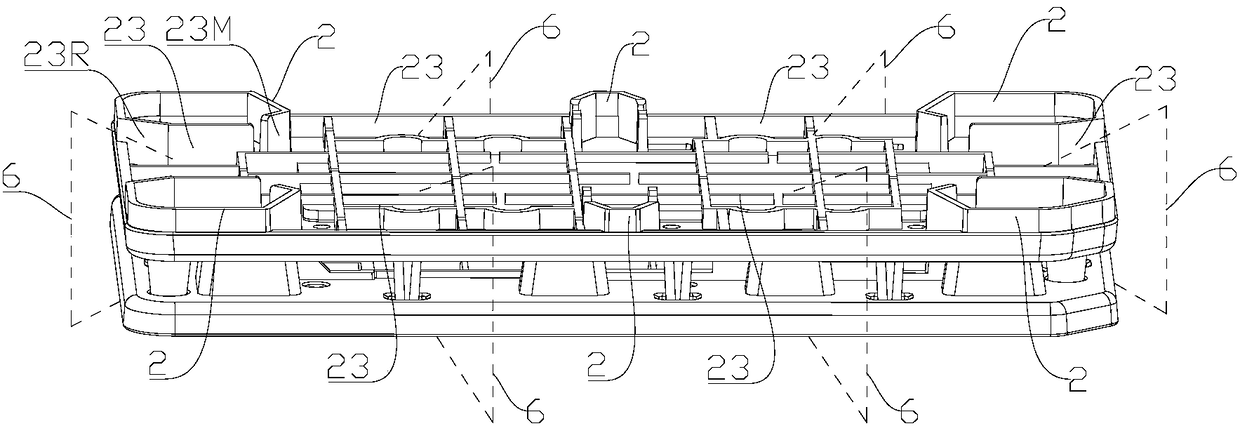

[0067] In the third embodiment, refer to Figure 6-Figure 7 , the position-limiting structure 2 is provided on the first cover 11 and the second cover 12, wherein the position-limiting structure 2 provided on the first cover 11 defines On one side, there is a limiting groove 23 for limiting the clamp 6, and the limiting structure 2 provided on the second cover 12 defines a side of the second cover 12 away from the first cover 11 for The limiting groove 23 for limiting the clip 6 is opposite to the limiting groove 23 located on both sides of the cover assembly 1 .

[0068] That is to say, in the present embodiment three, the limiting structure 2 includes both the above-mentioned first limiting structure 201 and the above-mentioned second limiting structure 202. At this time, the cover assembly 1 There are first limiting grooves 231 and second limiting grooves 232 respectively on both sides of the two sides, and the first limiting grooves 231 and the second limiting grooves 232...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com